Henry Ford believed in "vertical integration." That means, he not only made cars, he made the things that made cars like steel. He even had his own railroad. I believe it was Detroit, Toledo & Ironton.

|

| Robert Preis shared a photo posted by the Detroit Historical Society On May 17, 1920, the blast furnaces at the Ford Rouge Plant were fired up for the first time. Iron from the furnaces was transported directly to the foundry, where it was poured into molds to make engine blocks, cylinder heads, intake and exhaust manifolds, and other automotive parts for the Model T (which was still assembled in Highland Park). Gary Giannini: Is it true that before this Henry Ford would only get his steel from OH#5 in Homestead PA? James Torgeson shared Detroit Historical Society posted On May 17, 1920, the blast furnaces at the Ford Rouge Plant were fired up for the first time. Iron from the furnaces was transported directly to the foundry, where it was poured into molds to make engine blocks, cylinder heads, intake and exhaust manifolds, and other automotive parts for the Model T (which was still assembled in Highland Park). Learn more about the Rouge Complex in our online encyclopedia: https://detroithistorical.org/learn/encyclopedia-of-detroit/ford-rouge-complex |

|

| John Abbott posted River Rouge Ford Plant 1927 Robert Hagar I use to work there. Straight ahead would be where the BOF (Basic Oxygen Furnace) and mold room will be built. To the very hard right is Gate 1. This is where the big water tower would stand. This was torn down after the Russian steel co. took over the steel operations. The highline was to the right bank of the channel where they unloaded the ships. (The highline was an elevated railroad where they unloaded the coalcars from the bottom.) The coke batteries were to the lower right of the picture. The road to the right which would lead to Gate 1 leads to the building I first worked in. The EE bldg. It is hard to tell but may be in the picture. I also worked in the BOF mold room.Robert Hagar The buldings to the left were assembly buildings and when I worked at the mold room I would walk through them. Some were abandoned but others were in use. The metal shop was over there and they would do all kinds of sheetmetal work. |

|

| Association for Great Lakes Maritime History posted The freighter Edgewater returning to the Ford River Rouge complex at Dearborn, Mich., circa Nov. 27. 1936 (Source: The Henry Ford – Digital Collections). The name of the photographer is not included in the notes for the image. Additional Historical Information Launched in 1931, the freighter Edgewater was built at River Rouge, Mich. by the Great Lakes Engineering Works for the Ford Motor Co. The 300-foot [91m] vessel (LOA) was designed to transport auto parts from the Dearborn, Mich. to assembly plants in Chester, Pa. and Edgewater, N.J. To reach those plants, the ship sailed on Lake Erie, the New York State Barge Canal and the Hudson River. To allow it to pass under bridges over the Barge Canal, the vessel had a retractable pilothouse canalErie and folding masts and funnels. In addition to parts, the freighter was occasionally used to transport new Ford automobiles from Dearborn to East Coast ports for export. In 1942, the vessel was requisitioned by the U.S. War Shipping Administration for off-lakes service during World War II. In 1947, the ship was sold to Cleveland Tankers Inc. of Cleveland, Ohio. for Great Lakes service. It was then converted into a tanker at Staten Island, N.Y. by the Bethlehem Shipbuilding Co. The conversion work was delayed by a two-month shipyard strike. Once completed, the tanker sailed back to the Great Lakes via the Gulf of Mexico and Mississippi River. During the voyage, it took on a cargo of oil at Baton Rouge, La. On March 19, 1948, the vessel went aground near Grand Lakes, Ark. After its cargo was lightered, the ship was towed to Greenville, Miss. for repairs. An inspection determined the damage was too great to be repaired at Greenville. The vessel was then towed to Lockport, Ill. by the Federal Barge Line. From there, the Great Lakes Towing Co. towed the tanker to the American Ship Building Co. yard in Chicago, Ill. for repairs. On May 15, 1948, the vessel finally entered service just as Cleveland Tankers experienced a maritime union strike. On July 8, 1948, the ship suffered two explosions and a fire. It was carrying a cargo of 31,000 gallons of gasoline at the time. Nine crew members were injured. Seven were severely burned and two would later die because of their injuries. After being repaired at the American Ship Building yard in Chicago, the tanker re-entered service on July 21, 1948. In 1949, it was renamed the Orion. The vessel was permanently laid up at Cleveland at the end of the 1957 sailing season. In 1964, the ship was sold for scrap and towed to Ashtabula, Ohio for dismantling. The forward section was converted into a 120-foot derrick barge. While under tow, the barge sank in Lake Erie off Lorain, Ohio on July 23, 1968. It was later raised, beached and dismantled. Information Sources: William Lafferty |

Jul 22, 2035: Andrew Dean Aerial Photography posted three photos with the comment: "Algoma Innovator loading ore Sunday morning at Cliffs Dearborn."

[I have seen a comment about Cliffs closing this plant. I thought Trump's tariffs were supposed to help our steel mills. Not letting normal production take down the ore pile implies this was an emergency closing. What was the emergency?]

|

| 1 |

|

| 2 |

|

| 3 |

|

| Jason Pond posted The Rouge looking from the west side of the complex. Mid-2011. Rick Horstman: The white buildings Ford assembly. .The reddish building is the steel plant. Joseph Hardin: The two large white buildings are the hot dip and new cold mill,aka PLTCM,I worked at them each. J.E. Gadd: Where is this? Michigan? |

|

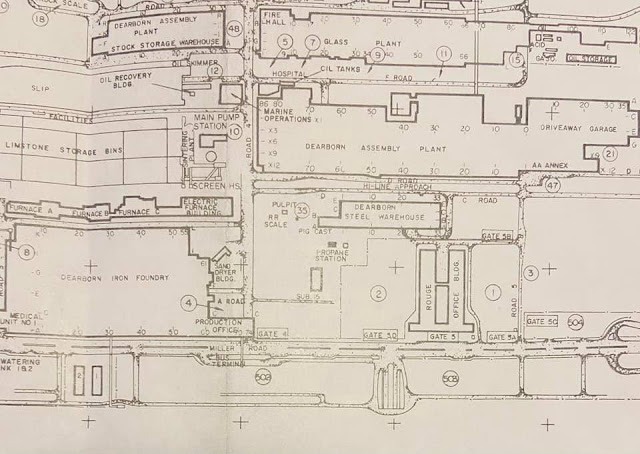

| Dennis DeBruler answered Gadd's question https://www.google.com/maps/@42.3029502,-83.1612203,3462m/data=!3m1!1e3?entry=ttu |

|

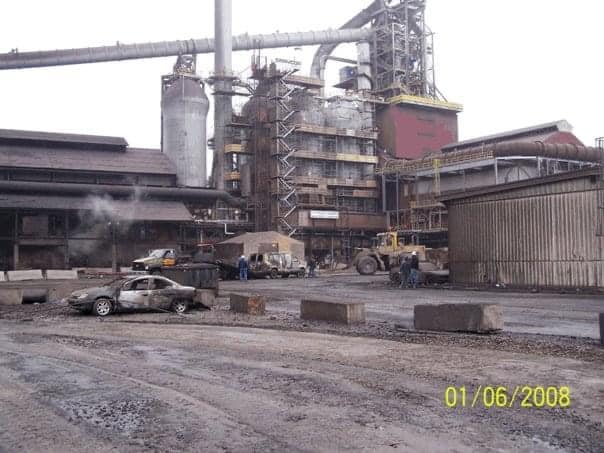

| Tony Vegas posted Furnace at the Old Rouge Steel in Dearborn Mi. Ralph DeAngelis: That's the one that blew up, right? Tony Vegas: Ralph DeAngelis that was B blast furnace that’s not seen but was to the right of the stoves you see in the middle. Left is A furnace which shutdown in 1988, and on the right is our C blast furnace with double tap holes. |

|

| Jay T Robinson commented on Tony's post |

|

| Ralph DeAngelis commented on his comment |

|

| John LaMothe commented on Tony's post |

Chuck Stephenson posted three photos with the comment: "Some pics I got from an old timer. Ford Rouge plant."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Mike Delaney posted First vessel to unload at Ford Rouge dock after river widening and changes. Cletus Schneider arrives to unload. 1923 [DT&I Bridge] |

Andy Payne posted three photos with the comment: "Construction of Henry Ford's Rouge steelmaking facility 1919."

|

| 1 |

|

| 2 |

|

| 3 |

Kevin Nelson posted two photos with the comment: "Ford Rouge Steel complex, 1931. (courtesy of the Ford Collection)"

James Torgeson: Showing the Rouge Plant's two Hulett unloaders, one of which was knocked over during WW2. One of US Steel's Michigan Limestone boats tangled with the Hulett and won!

|

| 1 |

|

| 2 [Some comments about Huletts, Brown Hoists and Mead Morrison coal unloading.] |

|

| Cosmic Enigmas posted Ford Rouge Blast Furnaces and Power House stacks. 1935 (courtesy of Ford Images). Kevin Nelson posted Ford Rouge Blast Furnaces and Power House stacks. 1935 (courtesy of Ford Images) Andy Payne: 13 years later (1948 ) C Fce was built. Richard Vertrees: Just watched a documentary on this place on YouTube. My boss is trying to get a field trip out together to go check it out. Said he went on a tour of it years ago. https://youtu.be/vuiJyWAW2Pk?si=-pjlmkoydpW3CWEx |

|

| Role Arjuw posted 1946 Ford Rouge Blast Furnace Building 0401-5639 |

|

| Alan Etoll posted Dearborn Works BF. James Torgeson posted The Cliffs Dearborn Works blast furnaces in a photo by Alan Etoll. John McDowell: Ashland Kentucky's replacement |

|

| William Opper posted C furnace. B furnace is gone and the whole top of A furnace has been removed. The stoves for them are still there. |

|

| Dean Okonski posted Rouge c furnace today [Jun 11, 2024] |

|

| Tony Vegas posted Original C Furnace in 1997 that Henry Ford built at his Ford Rouge Complex. Toby Salisbury: The replacement C furnace was probably the cleanest environmentally running blast furnace in North America. While in operation from a distance you couldn't tell if it was running other than steam in cold weather or driving by and actually seeing the iron and slag running into the bottle cars and slag pots. The furnace now needs to be relined along with both BOF vessels, vessel stack boilers and refractory stacks need replaced. The plant also needs a new hot strip and rolling mill that can run wider than the current 68" mill that has been shut down for years. I believe the reheat furnaces could be rebuilt and reused but the rolling mill would need complete replacement for wider slabs. I honestly don't think Cliff's has the money to do what's actually needed and they will only do enough to start the plant and then struggle with what wasn't repaired correctly for sustainable production. In my almost 40 years that I've worked as a contractor in many steel plants I've only seen major plant wide repairs/rebuilds done and that was Severstal at the Rouge plant. The work that Severstal did is the only reason that the steel operation at the Rouge lasted as long as it did. |

|

| Michael Kloeckner posted Rouge Steel Dearborn Michigan |

|

| Scott Noble commented on Michael's post B Furnace not sure what year |

|

| Robert Preis posted Ford Rouge - July 1969 Looking from Left to Right - you can see the stacks of the Dearborn Speciality Foundry, the BOF, the East Side Coke Oven Gas Holder, the framework of one of the Ore Bridges, and the Coke Ovens Smokestack & Transfer Tower Picture copied from Michigan Railfans site. Sam Foster - original image from the Gulash Collection Wade Klaffer: And to the far right is the powerhouse that blew up in 1999 |

|

| Rebert Preis commented on Derrick's comment |

|

| Mike Delaney posted Ford Motor Company Rouge plant 1958 |

Mide Delaney posted three images with the comment: "Ford Motor Company Rouge plant. Photo shows Henry Ford and son Edsel with scale model of rouge plant."

|

| 1 Bob O'Donnell In 1915, Henry Ford built the first Ford Motor Co. plant on the banks of the Rouge River in Dearborn, Mich. The site quickly grew to become one of the largest integrated manufacturing complexes in the world. The inbound transportation of raw materials and supplies by barge was part of Ford’s initial plans for the project. By 1923, however, the scale of the complex’s demand for raw materials for steel making required Ford to begin acquiring his own fleet of ships. The first two vessels in the fleet were the bulk carriers, Henry Ford II (1924-1989), and the Benson Ford (1924-1982). Named for Ford’s grandsons, both ships were built at the Great Lakes Engineering Works shipyard at Rouge River, Mich. Also, during this time, Ford purchased 200 surplus World War I merchant vessels from the U.S. government. Most of these ships were scrapped for the steel furnaces at Rouge River, but 22 were converted for use as barges, canallers, and ocean-going freighters to serve Ford Motor Co.’s export plants on the U.S. East Coast. The Ford Motor Co.’s fleet operation grew so rapidly that, by 1925, it was necessary to establish a Marine Department within the company. At the start of World War II, automobile manufacturing came to a standstill. The Ford fleet carried less raw materials and fewer finished parts to Ford factories forcing the company to place more emphasis on non-Ford cargoes. By June 1942, however, almost the entire Ford fleet had been acquired by the United States government for wartime service. After the war, several of those vessels returned to the Great Lakes and the Ford fleet. In 1953, Ford Motor Co. had the 629-foot bulk freighter, William Clay Ford built at the Great Lakes Engineering Work in Rouge River. In 1966, it acquired the 630-foot bulk freighter John Dykstra (ex-Joseph S. Wood, ex-Richard D. Marshall). In 1982, Ford converted its steel making operation at the Rouge manufacturing complex into a wholly owned subsidiary, the Rouge Steel Co. That same year, the Benson Ford was sold for scrap and the John Dykstra was renamed the Benson Ford (II). In 1985, Rouge Steel Co. acquired the 767-foot freighter Edward B. Greene. It was renamed the Benson Ford (III) in 1986 after the Benson Ford (II) had been sold for scrap. That same year, the William Clay Ford was also sold for scrap and its pilothouse was removed to become part of the Dossin Great Lakes Museum in Detroit. Also in 1986, Rouge Steel acquired the Walter A. Sterling (ex-Chiwawa) and renamed it the William Clay Ford (II). In 1989, after the company was acquired by Marico Acquisitions Corp., the Benson Ford (III) and the Henry Ford II were sold to the Lakes Shipping Co. That same year, the William Clay Ford (II) was sold to the Interlake Steamship Co. and renamed the Lee A. Tregurtha. Information Sources: |

|

| 2 |

|

| 3 |

|

| Raymond Boothe posted Cliffs Steel-Dearborn: this is a view of Cliffs Steel C Blast Furnace at its Dearborn Works. Originally built by Serverstal and acquired vt AK Steel this furnace is currently the newest blast furnace in the United States (unkn/Dr. Raymond Boothe collection). John Groves: Dearborn plant, originally Ford Motor Co., then Rouge Steel, then Severstal from 2004, then acquired by AK Steel 2014, then Cleveland Cliffs 2020. No.C BF built 1948 (8.4m), completely rebuilt 2007 ($350M). Severstal then rated the furnace at 6000 to 6200 tpd. Now 9.2m, 1797 cu.m. wv, producing 5000 to 5750 tpd over past decade. |

|

| Aaron Payne posted, cropped Little Burp outta Henry Fords B Furnace just before we moved over to C Furnace to tare it down and rebuilt it for them! 97 days from demo to a full rebuild 2007 Graham Whitfield  +2 My late Father worked on Blast Furnaces for 46 years, he used to describe this as a ‘Slip.’ When the built up Burden (Coke, iron ore, limestone) suddenly drops into the melting zone of the Furnace. Usually when the Furnace lining is getting worn. Flames shoot out of the top of the Furnace and night becomes day. If the Furnace is Casting molten Iron spews out all over the Cast House floor at pressure. Blast Furnace front side crew were a ‘special breed’ of men. |

|

| Wade Klaffer posted Cast house floor at Ford rouge [There are several interesting comments including terminology for those "gates."] |

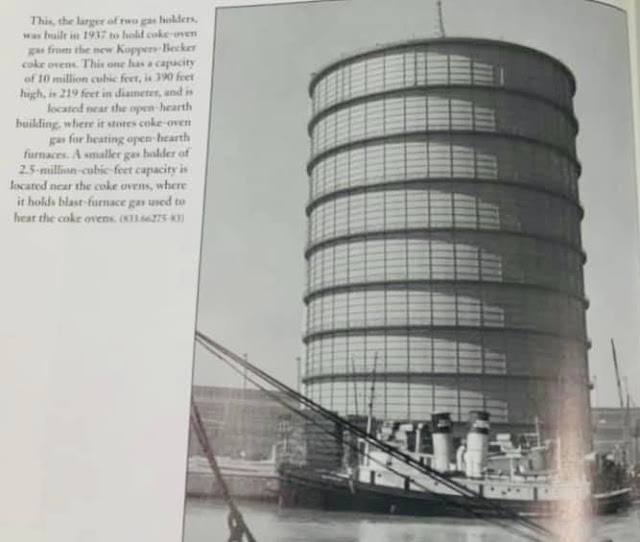

I added the "energyGas" label because of the gasometers in these photos.

|

| Wade Klaffer posted, cropped Aerial shot above the rouge river in the 60’s |

|

| Aaron Payne posted, cropped Little Burp outta Henry Fords B Furnace just before we moved over to C Furnace to tare it down and rebuilt it for them! 97 days from demo to a full rebuild 2007 Graham Whitfield  +2 My late Father worked on Blast Furnaces for 46 years, he used to describe this as a ‘Slip.’ When the built up Burden (Coke, iron ore, limestone) suddenly drops into the melting zone of the Furnace. Usually when the Furnace lining is getting worn. Flames shoot out of the top of the Furnace and night becomes day. If the Furnace is Casting molten Iron spews out all over the Cast House floor at pressure. Blast Furnace front side crew were a ‘special breed’ of men. |

|

| Wade Klaffer posted Cast house floor at Ford rouge [There are several interesting comments including terminology for those "gates."] |

I added the "energyGas" label because of the gasometers in these photos.

|

| Wade Klaffer posted, cropped Aerial shot above the rouge river in the 60’s |

Derrick Gow posted three photos with the comment: "Rouge Steel B Furnace 2001."

A Tuyere blew out. Iron and hot coke made it to the Natural Gas Injection station.

[According to some comments, they had another accident a few years later (2007?) that "blew the dome off." That accident shut down B Furnace B partially because C Furnace had been built and was bigger than A+B.]

Mike Benedict

Was the furnace full and the furnace was casting itself through the tuyere. It seems like Servestal had lots of safety problems. I have seen where a cast was delayed for one reason or another and instead of decreasing wind, they just waited. When the furnace gets to a level where you cannot cut the wind. At full wind the furnace burden is floating or being blown upward and when the wind is cut, the burden slips down and overflows the level of the tuyeres and the furnace starts casting out of a tuyere or several tuyeres. What a mess and hope no one is hurt. It is like having a glass of water and ice at the very brim and you push down the ice, like cutting the wind and the ice will make the glass over flow. Same thing with a blast furnace.

|

| 1 |

|

| 2 |

|

| 3 |

Elvin Howland posted five pictures of the steel operation, each with their own comment.

A time-lapse video of the Herbet C. Jackson being pulled out of the Ford slip and then going down the Rouge River until it gets into the Detroit River.

Robert Preis posted two photos with the comment: "Rouge Steel - Powerhouse Stack & Coke Ovens Demolition - Summer 2004."

Scott Marlow posted twelve photos with the comment: "More....." (I believe this was his first set of photos that he posted.)

|

| 1: To All: Newly poured slabs ready for the rolling mill in the Ford Rouge Steel Plant. Taken in the 1970's. Photo by Elvin Howland. |

|

| 2: To All: A bottle car being filled with molten steel in the Rord Rouge Steel Plant. It was raining that day. Photo by Elvin Howland. |

|

| 3: To All: The quench tower being used to cool down a hopper load of coke in the Ford Rouge Steel Plant. Taken in the 1970's. Photo by Elvin Howland. |

|

| 4: Ditto. Photo by Elvin Howland. |

|

| 5: To All: A Ford Switcher pulling a mill gondola in the Ford Rouge Steel Plant. Taken in the 1970's. Photo by Elvin Howland. I worked under contract for Ford Motor Co. to clean their directional signs and the Ford oval sign on the coke tower. This sign was 200 feet off the ground and was 90 feet long by 35 feet high. While up there I saw a nine locomotive Conrail freight go by. Outsiders were not allowed to have a camera in the plant, but I sneaked one in and took these photos. This plant was one of the largest in the word, being self contained, with an electric plant, blast furnaces, and an auto plant and other facilities. In WW II the plant built Liberty Ships. Aaron Angle They actually did not build liberty ships at the Rouge plant during WWII. They did however build Eagle Boats, which were submarine chasers, there in WWI. These are great photos. Thanks for posting them. |

|

| John Abbott posted River Rouge Ford Plant 1930's |

|

| 3D Satellite |

|

| Alec Gills posted Ford Steel Division (Rouge Steel) back in the 70’s... Howard Harwood I remember pouring ingots |

Robert Preis posted two photos with the comment: "Rouge Steel - Powerhouse Stack & Coke Ovens Demolition - Summer 2004."

Scott Noble It did until it blew up.

Johan Gillies Heins R.I.H. 21 years ago, In Everlasting Remembrance of 6 of my ‘co-workers’ who perished that cold February day. 01-Feb-1999

https://www.freep.com/.../ford-rouge-power.../2731695002/

https://www.freep.com/.../ford-rouge-power.../2731695002/

|

| 1 |

|

| Alan Etoll posted [A summary of the comments: C-Furnace AK Steel Dearborn Works, formerly Ford Steel Division.] |

|

| Screenshot AK steel Dearborn works, ore bridge crane demo 9-22-2017 What the hell is going on there? No more blast furnace production? Viktor Mácha no.. that ore bridge got Demi’s beacause it got destroyed from a strong wind storm. There is another one if you look to the left. |

|

| Nagi Nasser posted [The comments indicate it is being put back in service. I assume it was shut down for Covid-19.] Bubba Dubs This is AK Dearborn/Rouge, Former Severatal, former Rouge steel. Brian Stevens John Orlando the plant was government subsidized during WWII for Republic Steel and made large gun barrel. Ford obviously bought it the late forties and ran a Forging Plant there. The ESOP, the employee buyout of LTV's Bar Division, purchased the building for a continuous caster. The history between Ford, Republic and Canton, Ohio runs a little deeper. |

Is the hot strip at Dearborn down forever? I used to deal with AK when it was Armco and supervised contract work at Middletown No.3, Hamilton Blast Furnaces and Amanda and Bellefonte at Ashland. I understand Cleveland-Cliffs has no plans to ever start Amanda again so I guess it is the wrecking ball for her. I never could understand why AK closed the hot strip in Ashland and only sent slabs to Middletown like they are doing to Dearborn. I know the tonnage on Middletown No.3 has been increased. I can't imagine the Middletown Hot Strip rolling more than 10,000 tons per day. It seems that both blast furnaces are capable of making much more than that so running them slow increases costs, even with smaller tuyeres and then the transportation costs by rail make the slabs expensive. I can see why AK and now Cleveland-Cliffs stock is so low....

Author

HSM Dearborn no longer functioning.

We use to send over 200 slabs per shift into the HSM! I still can’t believe it was shut down! Another sad day for Steelworkers!

|

| 1 Mighty Rouge’s Ford Steel Division HSM.... I was the first woman to work that Building, 1978. A lot of pro’s and con’s, but I was a ‘smooth operator’ in every crane in there! |

|

| 2 |

|

| 3 |

|

| 4 That pots got some crack |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 The Big Kline |

|

| 9 That’s a problem |

|

| 10 |

|

| 11 68' Oxygen Lance it's fun when you blow a hole in it and all the cooling water drains into the vessel... Oxygen Furnace is a crazy place to work, especially in the ingot days! Oh yeah! |

|

| 12 |

|

| Jason Dodson posted, cropped Wet charge at the BOF [The comments indicate this was at the Rouge. I think a wet charge means there was water in the scrap metal container. When the water hits the iron in theBOF, you get instant steam. Steam expands explosively.] Beau coup dust from the rafters, too!  Really that’s from a wet charge? Man I’ve looked down the barrel of a wet charge it’s intense but never saw the cloud outside of one lol Author Chris Cox oh yea we were probably 3/4 of a mile away and felt the percussion it was a big one. One of the other guys I work with had gotten hold of the video from outside the door it blew molten iron pretty far outside the building too. Glad no one was injured.The real big boy was the burn thru into the trunnion. Talk about a wet charge. Since it's AK Steel you know someone is getting fired for this. Someone has to hang. |

Shane Pappas posted nine photos with the comment: "Tearing down and rebuild of brand new furnace, think we did it in 05 or 06 its been so long g ago now. Old furnace to brand new working work 94 days!"

David Bandel: SeverStal, 2007. It was a great project.

Shane Pappas: The pic with the crane lifting the 3 story section was the largest lift at the time that crane had ever dont was if I remember it was like 1.6 mil pounds, was enough to lift all that trailing counter weights off the ground. Hard to tell from pics but the tires on the counter weights are like 15ft tall too. It was a monster crane.

Justin Snyder: Big crane is a Manitowoc 21000 with Maxxer wagon.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| Scott Marlow commented on Aaron's post |

|

| Aaron Payne commented on Shane's post [Note that the wheels of the Maxxer Wagon are off the ground. This is normal for a 21000 doing a heavy lift. But it does mean it is doing a heavy lift.] |

|

| Aaron Payne commented on Shane's post little burp |

|

| Aaron Payne posted 1,000,049 lbs stack section going up on a 97 day total rebuild from demo to ground up. 2007 Rouge Steel, Detroit MI. Henry Fords third blast furnace. The last and only still chugging iron out today out of three they had. Mark Goodrich: 21000 Manitowoc [I thought so because it has eight crawler tracks.]Jesse Linklater: That crane is currently replacing the steam generators where I work now at Bruce Nuclear. Brian Olson: Probably the last blast furnace that will ever be built in the US. |

|

| Scott Marlow commented on Aaron's post Same crane as the poster.... |

|

| Matthew Gilbert posted BOF and Caster at the Rouge with Detroit in the background. [drone] |

|

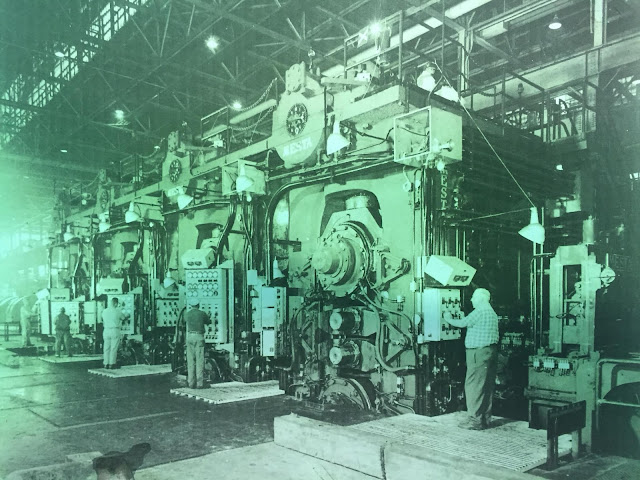

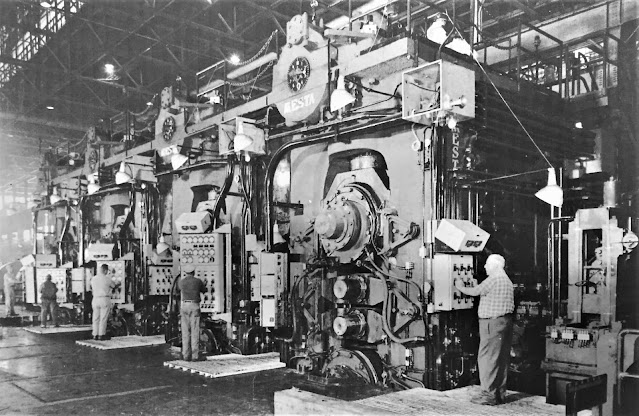

| Matthew Gilbert posted Found this picture of #2 tandem mill at the Rouge in the Cold Mill offices. Rick Kusbel: Same vintage as the Gary works 5 stand. Housings, chocks, and entry princh roll arrangement all look the same. Thomas Izzo: crane operator Stanley king could pulled off a general roll change in 18 minutes . Hold the cables, then stand back and watch him go. Ray Kankoski: Did you ever see the old picture of the 8-2 hot strip mill with the standing by each roll stand making adjustments while the strip was going thru ? [I've been wondering how the old mills were controlled.] Tom Lareau: Not a single hardhat in that picture. Michael Matisko Mesta mills encountered in my time with Alcoa: Warrick #4 Cold Mill (6 stand, 60 inch wide) Davenport Reversing Hot Mills (144 inch and 160 inch wide) Davenport 5-stand Hot Mill (100 inch wide)—replaced by SMS mill of same configuration/width early 1990s |

|

| Wm R. LaDow commented on Matthew's post |

|

| Scott Marlow commented on Matthew's post same mills - Severstal era..... |

|

| Brian Olson posted I remember talking with a guy that commissioned the 68" hot strip mill at Dearborn Michigan in 1974 which was built by Blawknox. He told me this mill had a system for changing the profile on the work rolls. There was a hole drilled down the center of the rolls and high pressure hydraulic oil was used to change the profile of crown on the rolls by varying pressure. Don't know how well it worked or if any other mill ended up utilizing this technology. Kind of sad about Dearborn. If it were a 80+ hot mill it probably would still be running given it was the last generation II hot mill built in the United States. Bill Hogrebe: Reagan is the one that ended manufacturing in The US. He wanted and got a financial economy controlled by Wall Street and changed tax laws to facilitate the export of manufacturing jobs. |

|

| Aaronn Albertt posted SEVERSTAL,DEARBORN Fertiggerüste d. Warmbandwalzwerks, Finishing Stands At The Hot Strip Mill. Christopher Getts: Looks hollow without the,work rolls. Michael Vincent Zynda: Hot Strip at Fords , I rolled a few thousand tons there too , shitty mill compared to GLS. I could bend the rolls both ways too, for crown .roll changes only took 8 min. too. . |

Marty Bernard posted three photos with the comment:

3 Ford Motor Car Co. Train PicturesDuane Hall took these three photos in sequence. There are no other similar slides, location is unknown, and the date on the slides is September 1978.Of what are the first two slides?The switchers are S4 10012 built 1948, S2 10013 built 1954, and SW1001 10022 built 1975, according to Diesel Shop. Basically what are/were they used for?

Karl Swartz: Interesting photographs. The first two are a bottle car (for molten metal) and slag car, respectively.

As for the locomotives, you swapped S2 and S4, i.e., 10013 is an S2 (not S4), etc.

Marty Bernard: Karl Swartz Is the Diesel Shop roster wrong? I thought it was weird too.

Karl Swartz: Marty Bernard, if that’s what their roster says then yes, it’s wrong. Just look at the trucks: the only difference between the two models is that an S-2 has Blunt trucks like (10013) whilst an S-4 has AAR Type A trucks (like 10014).

Alco made a clean switch from Blunt to Type A so the dates also don’t make sense unless you swap models. With that change, they are plausible, but I didn’t research the details to see if they match production timeframes of those models.

Mel Baggett: They transferred from our blast furnaces to our BOF. But the Ford railroad services the overall Rouge complex.

Richard Custer: Bottle car is parked at entrance of pig cast with Dearborn assembly in background.

Craig Ealey: The S2 10013 was built in 1948. That unit has the blunt truck which was discontinued in 1950 therefore it couldn’t have been built in 1954 the S4 was probably the 1954 build date as it has the AAR truck.

Marty Bernard shared

John Sporik: These were called hot metal subs and the other were ladle bowls. I worked at Bethlehem Steel.

[There are some comments about million pound open ladles that carried molten steel from Middletown, OH, to Hamilton, OH. A bridge was built exceptionally strong to handle those cars.]

Ray Schloss shared

Derrick Jasper: 3rd picture is looking south at the 3 blast furnaces at Ford Motor Company Rouge Complex. Not sure of date but it appears it’s pre 1986 as it appears all 3 furnaces are in use.

|

| 1 Robert C Hecker Sr.Doug Majka: Riveted construction so it must be an oldie, but probably overbuilt way back then to last forever. |

|

| 3 Richard Custer: .c furnace is 365 feet high was the second highest building in the rouge. Glass plant was tallest. Warched the city burn from the top of glass plant in 1967. |

|

| Robert's diagram |

Kyle Lang posted six photos with the comment: "Pictures from the breech of B-Furnace at the Rouge plant in Dearborn Michigan (Severstal owned at the time), circa 2008."

Jeff Butcher: Ravi Eh that's a stack breakout. Caused by loss of cooling for a long period of time or you lose the refractory inside the furnace stack.

Ted Fortier: Downtown was permanent. Only the stoves stand today with pilings for a new furnace.

Jason Stevens: It was a bad day. If I remember correctly no one got hurt. That was a miracle in its self.

Scott Noble: Jason Stevens The person driving in the van got hurt I believe he lost a finger he was driving down the road at the time of Explosion he worked for the water department he was contractor.

Kyle Lang: Pat McCon no one died in this explosion, which was around midnight on a weekend and between shifts I think.

Scott Noble: I work there for the fire department we had to drop off fire hoses all the time they used to hang them from the top of the furnace to cool the hot spots at night you could see all the hot spots.

Ran it for months with hotspots on it everybody knew it was a matter of time not the best safety department at the time.

Nathan Jay: Was the company fined or anything for it? Documented problems and no fix, crazy! Hopefully no one was injured/killed.

Scott Noble: Nathan Jay Big cover-up between management and safety department.

Donald Hall: Anyone injured ?

Joseph Whitman: Donald Hall only one person he was a outside contractor in that white van. Dummy pulled right in front of furnace after first explosion and a second happened and sent debris right at his van he ended up getting burned a little bit but I’m sure it was more of a lesson not to be so nosey and don’t ever park in front of something that blew up because you never know what will happen. Other then that we had a few supervisors lose their cars but no injuries. For myself and the other 2 workers we made it out alive but it’s something we’ll never forget.

Donald Hall: Joseph Whitman Can imagine ! Had moulds blow up a few times next to me on the pouring aisle. Lots of scars.

Chuck Francis: I remember that day. We religned that crinkly cracked up old girl just a few months before she finally gave up the furnace looked terrible from the inside.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 1st of 4 photos posted by Andrew Dean Detroit Mark W. Barker preparing to tie up for their first unload at Cliffs Dearborn yesterday. Detroit / Dearborn, Michigan Andrew Russell shared |

William Opper posted two photos with the comment: "Hauling slag."

[Some comments indicate this is Cleveland Cliffs in Dearborn, MI, and the furnace makes 12,500 tons of iron a day. It is a Levy pot hauler.]

Michael Swift: North side C furnace Cliffs Dearborn

|

| 1 |

|

| 2 |

|

| Dean Okonski posted 45 foot tall towering c furnace at Dearborn works. Andrew Hildinger: A lot taller than 45 ft Eric Galassi: That furnace is probably about 300 feet tall to the very top. Inland #7 Is 310 feet tall Roger Kalinowsky: The C furnace baghouse stack is 200 feet & I believe the top of the furnace is even taller. John Balik: When Sevesatal rebuilt the furnace in 2007 we used an M21000 with 320’ of main boom. It didn’t have a jib. Furnace was definitely less than 300’ tall. |

|

| Andy Payne commented on Dean's post Here is a Dwg from our lift plans, I think the 21000 had 380 and we took 40 out to make the 500-ton lift. |

|

| Charile Whipp posted After you're done making steel for the day at THE ROUGE, stop in for a cold one at Little Jo's. 🙂 June 1986 Dearborn, MI. Little Jo's was featured in the movie (1978) "Blue Collar". It was razed several years back. James Torgeson shared The long gone gas holder [gasometer] from the Ford Steel Division at The Rouge, and a requisite dive bar outside the gate (also gone)! Photo is from mid-1986. |

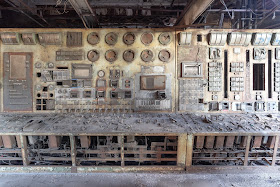

Detroit Unseen posted ten photos with the comment:

Ford Motor Company River Rouge Power Plant. Built in 1921 this power plant supplied the power to run the entire River Rouge Production Plant and more. The edifice consisted of red brick and featured eight 333-foot-high smokestacks protruding from the rooftop. Each of these smokestacks were connected to eight turbo-generators, each of which had a capacity of 35,000 horsepower. The generators were all powered by giant boilers that were heated in turn by pulverized coal, coke oven, blast furnace, or natural gas - used individually or in a mixture. Tragically on February 1, 1999 a natural gas explosion inside the Rouge River power plant killed six Ford employees and injured several others. The massive force tore through the aging power plant, shattered the control room gauges, blew the roof off, and was described as a “scene from hell” by witnesses. Some of the evidence you can as you can see in the photographs, which were taken some 21 years later. The power plant was demolished in 2025.

Maison Young shared

Russ Crenshaw: The smokestacks were connected to the boilers, not the generators. They were steam driven turbines not turbos. Turbines connected to and turned the generators

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

Sam Foster posted five screenshots with the comment:

RIP Dearborn Works. Here are some drone images from May 2024. Wish I got a second chance to visit, but I’m happy with what I got!

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| Galen Witham commented on Sam's post Research...... |

|

| Dearborn Historical Museum posted Clevelands-Cliffs Dearborn Blast Furnaces reportedly shut down this past weekend for what is deemed an indefinite period. As Cleveland Cliffs owns the former Ford Rouge steel complex site, this effectively marks the end of 105 years of blast furnace operations in that area. Here's an early Rouge plant blast furnace pic in our collection showing the area in 1927. Steve Hall: Only one blast furnace shown in pic, on far left. Can't remember if it was Furnace A or C. It's a great photo for me, as it shows the Powerhouse, Pulverizer building, the Benson in the slip, the High Line, and the 2 furnace stacks of the Coke Oven batteries. I worked in all of those, mostly as a powerhouse mechanic/machinist, earlier as a coke oven machine operator, and as a laborer on the High Line where we would do clean up duty in the holds of the boats, since they, except for the Henry Ford 2, were not self unloaders. During my time, the Benson was a coal hauling boat. Mark Brown: The finishing facilities at Dearborn—including the pickling line tandem cold mill and continuous galvanizing line—remain open. Around 550 employees continue to support those operations while the steelmaking portion is idled. Lee Hickmott: I think this was the last mill in Detroit metro area. Very little steel making in the motor city today. Cleveland Cliffs have closed 4-6 mills in the last 6 months. Eddie Makarek shared Chris Mahn: It’s totally down and tapped |

%20Clevelands-Cliffs%20Dearborn%20Blast...%20-%20Dearborn%20Historical%20Museum%20_%20Facebook.png) |

| Comments on the above post |

|

| Scott Marlow posted 75 ton roughing mill gear Rouge Steel - Dearborn, MI Don Sigler: They had to make a cradle for that thing. The timbers were starting to lean. That Gear is still there. Along with a couple others. |

lll

|

| Scott Marlow commented on his post |

|

| Scott Marlow commented on his post |

29:03 1960s video, (source) This is about the plant but does include the steel operation including the coke plant

17 photos of Wilfred Sykes loading and Herbert C Jackson unloading

10 photos including some aerial photos

1:19:45 video of "B Furnace Reline 1997 - Rouge Steel" (source) It didn't watch it because it is a bunch of detailed shots that don't mean much to me. But maybe it will mean something to others.

Cleveland Cliffs (CLF) has taken over the facility and I hope they do a good job with this famous American steel works and their well paid workforce.

ReplyDeleteNothing like it on Earth. Awesome.

ReplyDelete