LTV was on the west side.

Inland got started as Chicago Heights Steel.

The roundhouse has its own notes.

A higher resolution:

Photos of the 2021 repair of Blast Furnace #7, the largest blast furnace in the Western Hemisphere.

|

| Mike Delaney posted Panoramic view of Inland. Shows A and B furnaces on the far right bottom. Built for the US defense plant corporation. John Groves: Mike, that is an awesome picture of Indiana Harbor in 1943. In the top center is the relatively new No.2 Open Hearth shop. With 24 furnaces in a row, it was probably the longest single-row open hearth shop ever built. My records indicate No.2 Open Hearth shop was built in stages. The first 10 furnaces were started up in 1917. Four more were added in 1924, one more in 1929, four in 1936 and five in 1937. Nathan Leindecker: Where did you find this. It’s spectacular. Mike Delaney: Nathan Leindecker Inland Steel 50 years 1893 to 1943 anniversary book. |

A higher resolution:

.jpg) |

| 1 of 74 photos of the Calumet Region shared by Michael Siola of his post |

|

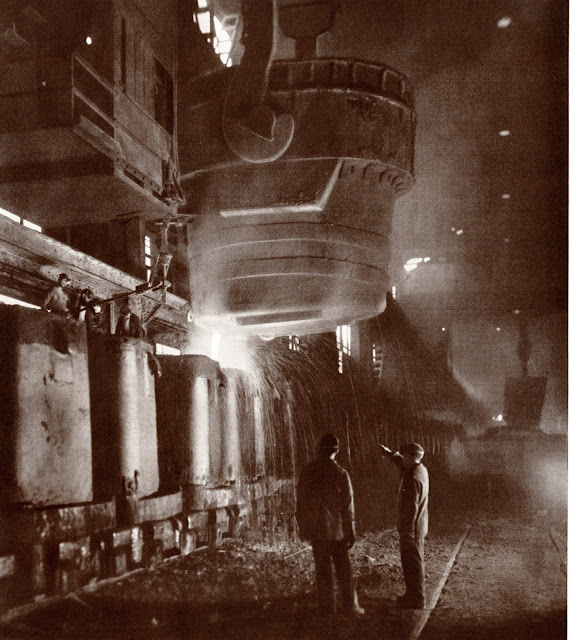

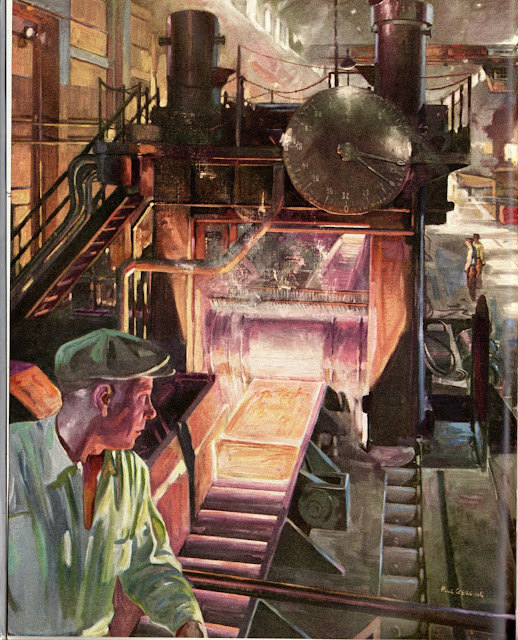

| John Groves commented on his comment If you can find an interior picture of one of the open hearth shops, it should be reasonably clear which shop it is. No 1 shop has only 12 furnaces, while No.2 had 24. This picture of No.2 shop shows the furnaces disappearing off into the far background. This 1947 picture is from the Inland Steel collection at the Indiana University Northwest Calumet Regional Archives. |

I wish I had seen this map when I started writing these notes rather than long afterward. It does show the old parts as well as the new part.

Trebor Thee Trebor posted two images with the comment: "This is a map of Inland Steel and the other side is the process of how to make steel.."

Steve Pajak: What is the year that this map was issued?

Keith R Phelps: Steve Pajak it’s showing 7 furnace under construction, so pre 1980. I can’t see any date in the photo.

|

| 1 |

|

| 2 |

|

| Frank Newton posted Frank Newton shared #7 Blast Furnace . This was took when Inland Steel was running the show . Inland Steel staff photographer Tim Fuller photo credit . Sam Burkett: Engineered by Koppers. I designed the stove hydraulics around 1978. I quit Koppers right after I got back from the startup at Sparrows Point. I didn't want to spend my life on the road. Frank Newton shared again |

|

| James Torgeson posted The Indiana Harbor Works of Inland Steel as seen from Lake Michigan. |

|

| 1965 |

Before the landfill was built.

|

| Kevin A Heggi posted Inland Steel 1913 Bert Pass: First blast furnace in Indiana. |

|

| 1 of 74 photos of the Calumet Region shared by Michael Siola of his post |

|

| Kerry Duvall posted This is an aerial photograph of Inland Steel from July of 1937. Taken by United Airlines. I got this photo many years ago off of eBay. Frank Newton shared |

|

| Larry Candilas posted Inland Steel, East Chicago - 1949 looking NE Curt Zehner: I can’t even recognize the place . There’s no 7 BF, 4 BOF, 2 BOF, 84”, Cold strip, or Sun Coke. The place sure has changed. Frank Newton: Shows part of Plant 3 , all of Plant 1 and Plant 2 and the lake being filled in for expansion. Jerose Park wasn't even built yet but was in planning stages . Youngstown Steel on the left of the ship canal . |

Christopher Camalick posted two photos with the comment: "My alma mater, the original Inland Steel Company at the Indiana Harbor."

|

| Tom Logan Novak posted "It looks like Plt. #3 "A" Furnace. Overhead Conveyer is the coke belt from "C" Battery. Cast House is off the Side not in line. Right to the left is the Pig Machine dump tower." |

Kevin Piper posted a history, a YouTube link and 13 photos. At 4:24, the video explains that #7 is 30 stories tall and can make up to 10,000 tons per day.

Frank Newton: Not much left of the old Inland Steel . One standing and operating Blast Furnace left . Used to be nine . BOF, Caster, 80" Hot Strip , Cold Strip . ArcelorMittal pretty much gutted and scraped 75% of the mill . I spent 35 years there and my family started in 1912 .

Jeff Marsh: Yeah Frank, we both started around the time things were booming, had to wait a long time for a close/decent parking space or have a long walk to the gate, most every department was running,,, now it's a bleached skeleton of what it once was. Always wondered why the shuttered depts. stayed and not re-used for something else, or leveled.(tax benefits can only be a good thing for so long IMO) 2 coke was leveled fairly quick after it shut down (for obvious reasons IMO, out of sight, out of EPA's sight for pollution/Hazmat conditions/fines) IF/when the depts. that have been closed over the years (in addition to those that have been leveled already) places like Plant 2 is going to look more of a parking lot than it is right now. All we have are our memories,,,,

|

| [Full resolution] |

|

| Bob Lalich commented on a post Here is an old aerial view of Inland Steel, with a circle around the area of the photo above. The street was the entrance to Plant 2. [The post has a photo of Michigan Avenue when it was still a grade crossing across all of those tracks.] |

LTV on the left, Inland on the right.

|

| Kevin A Heggi posted Indiana Harbor Works, circa 2005? Ian Christiansen: That pic is a bit older than 2005. A&B furnace Are still standing in plant 3 (bottom right). Those came down about August 2004 if I remember correctly. I was on shift the day National blew them down. It was wild watching the shockwave ripple the windows on the bar mill office across the street at plant 4. Aaron Terres: Ian Christiansen what company were those old furnaces from originally? Also is that a railroad roundhouse above and to the left of the old furnaces? [Indeed, it was a roundhouse.] Ian Christiansen: Aaron Terres plant 3 was originally built for the dept of defense by inland to help supply ww2 and purchased from the dept of defense afterwards. And yes that’s the round table in plant 1 visible. James Torgeson: Ian Christiansen You mean the Defense Plant Corporation. The DOD wasn't created until 1947. Steve Herrmann: I can just see the 12” bar mill peaking out at the bottom of the pic. [Some details about the roundhouse next to the east side of the canal are here.] Robert Dorsey posted Indiana Harbor and Ship Canal James Torgeson shared The former Youngstown Sheet & Tube is at left and former Inland Steel is to the right. Now both are Cliffs. Date not noted. Thomas Lusby: That’s a old photo And B furnace are still standing |

|

| Comments on Kevin's post |

|

| Andrew Mark Popagain posted [Comments indicate this was at Inland.] |

|

| Jim Prrfan posted Inland plant #3 Jim PRRFan photo |

|

| Jim Prrfan posted Jan 25-2004 Jim PRRFan photo Thomas Lusby: Plant three A furnace |

|

| Jim Prrfan posted Inland plant#? 4-24-04 Jim PRRFan photo Thomas Lusby: What a great picture!!Plant three B furnace |

|

| Jim Prrfan posted April 24 2004 From Cline ave. bridge. Jim PRRFan photo Ron DeMack: [Plant 3] A & B Furnace...built by the government during WWII..to support the war effort. Not sure if they were given to Inland after the war or sold to them. Across Dickey road to the weat was "Cast Armor." Charles Puckett: Ron DeMack Cast Armor made tanks in WWII for the Army. Later it was sold to Inland and converted to an electric furnace. I was told it was shut down. [A is the one closest to Dicky Road. They were "energetically felled" a couple months after this photo.] |

|

| Jim Prrfan posted Inland Steel Blast furnace row along IH canal. Jim PRRFan photo |

|

| Kevin A Heggi posted Inland steel, from the Cline Ave bridge Randy Clayton: Plant 4, spent some time there. Jason Morris: This whole plant was shut down a while ago. EAF and bar mill. [Another comment implies the bar mill was 12".] |

|

| Street View |

|

| Jim Prrfan posted Inland from Cline Ave bridge. Jan 18 2004 Jim PRRFan photo Michael J Mikula: All gone now. |

|

| Jon Wolfe posted Control pulpit for new 12-inch bar mill, July 15, 1969 Inland Steel Indiana Harbor Works Charles Gardineer: No computers that guy could make you or break you. |

|

| Ron Kaszak commented on Jon's post |

|

| Kevin Braden posted Picture I had put away, Lime plant , Cleveland Cliffs , Inland Steel Bill Cravens: Worked at 3 Open Heart, right next door, for years! [But I also don't know the location of OH#3.] |

|

| Reynaldo Ron Cortez commented on Kevin's post Stone stacker |

|

| Rick Kusbel commented on Ron's post |

Norman Hinga posted two photos with the comment: "My memory of a hammer drop forge is of one at Inland Steel E. Chi IN. It was located along a street at a red light intersection in East Chicago. When you pulled up to the red light it hammered so loud you felt the shaking. in your car. Ear protection definitely required but that was in the '60s and was accepted as normal mill noise."

Michael Babbitt: Standard Forge. They beat out train axles and wheels.

Michael J Mikula: The one next to Dickey road was Indiana forge. You could see the forgings being made. Across the street was Standard forge. Indiana on the north side of the road.

|

| 1 |

|

| 2 |

|

| Randy Lentz commented on Norman's post Staring at one right now. |

(Update Apr 2022: The EAF and Bar Mill is no longer rusting away because it is being torn down. A video of the demolition)

|

| Screenshot @ 0:14 |

|

| Raymond Boothe posted Builders photo of Inland Steels' (Now Cliffs Steel) Blast furnace No. 7 (Inland photo). |

|

| Rick Craven posted, cropped #7 BF Cleveland Cliffs , East Chicago Indiana [Comments indicate it was taken Nov 8, 2024.] Jerry Jung Sr.: Don't want to be near it when the burden slips. Allan Phillips: Jerry Jung Sr. Early on I was at the base of the big conveyor when the furnace kicked. Two bleeders opened, sounded like jet engine, and the jet went 100 feet up. Another time I was at charging level when it slipped. The whole flipping tower shook. The first few years were rough, burden-wise. The coke from soft Illinois coal never worked like they thought, but once they got better coke, it didn’t slip much. Not in my time anyway. |

|

| Vincent Marcel de Santiago commented on Rick's post [I think the bleeders are open in this photo.] |

%20Steel%20Mill%20Pictorial%20_%20%237%20BF%20Cleveland%20Cliffs%20,%20East%20Chicago%20Indiana%20_%20Face.png) |

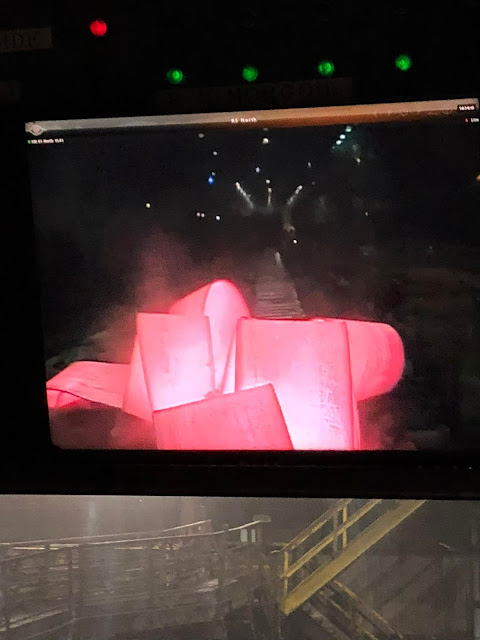

| Zachary Vesely commented on Rick's post Opening 4 tap hole [Zachary's comment was a video, and this is a screenshot at 0:05.] |

|

| David S Baldwin Jr. posted, cropped Cleveland Cliffs/Inland Steel Plant 2 Blast Furnace 7 [The comments agree it is the second biggest in the world. But they disagree on the capacity. The numbers are 14 and 12,500 tons per day. 14 has to be wrong because most ladles hold more than that.] |

|

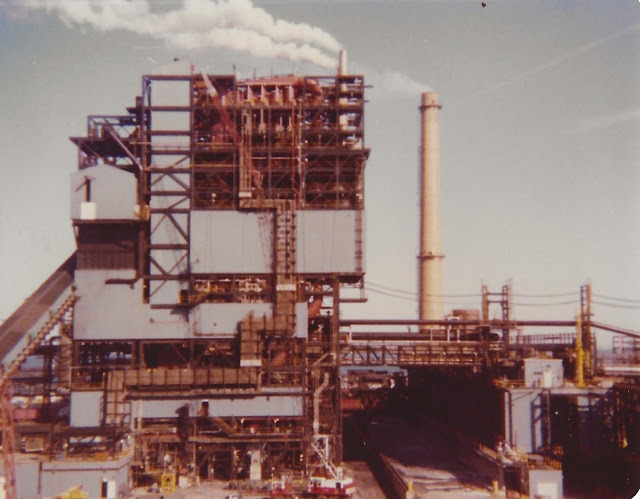

| Tom Cera posted Cliffs IH #7 Blast Furnace under construction - 1979. David Marshall: Producing way above its design size. Great example of continuous improvement. |

|

| Joseph L Miller posted #7 Blast 💪 Adam Carl: They got it put back together yet? David Cullum: Adam Carl supposed to be up Thursday [Nov 16, 2023]...we feed that monster coke. |

|

| Tom Cera posted, cropped From left to right, #7 Blast Furnace under construction, #11 Coke Battery and #4 AC. Inland Steel, East Chicago Indiana USA. Circa 1978. Allan Phillips: I was hired in Feb 1980 as one of the first engineers at #7. I went into Finance in ‘87. The real killer was the financial structuring of Kote. Nick Hlavaty: The slide began in the mid 70s with the Billion Dollar Northwest Expansion. Then Inland started buying hundreds of tons of slabs from Brazil. And, as always, the USW was blamed for the shrinking profits. Inland squandered $100 Million on the purchase of J M Tull Steel Service Center at a premium from Bethlehem Steel. Inland management after Fred Jaicks made many amateur missteps. Luckily, Inland was rescued by Ispat, Arcelor Mittal, and then Cleveland Cliffs. But my pension is still providing in part for my retirement, and that's what matters most to me. Richard Greene: Excellent picture. Great to see that. Thanks. I’ve relined this furnace twice ‘14&’21, the most recent fire repairs, and countless maintenance shutdowns. Sam Burkett: I did the hydraulics for the stoves. original cost was around 250 million. It came in around 450 million and over 2 years late. It was designed by Koppers. Inland ended up sueing Koppers for cost overruns. Last blast furnace built in the US. Sam Burkett: See Koppers vs. Inland 1986. I worked at Koppers and was at Sparrows Point for 9 months. It had a penalty contract. The EPA was charging Sparrows Point 1 million a month that it went past start up. I believe Koppers and Bethlehem Steel split 2 or 3 months of the charge. When I came back from Sparrows Point in September 1978, Koppers was only a shell of itself. I left Koppers for Wean United then. Michael Hansen: Also #4 AC Station far right . 2 stacks |

.jpg) |

| Derek Helsing posted, Oct 27, 2023 Cliffs IH7 Furnace |

|

| Raymond Boothe posted Aerial view of Cliffs No. 7 blast furnace (unkn/Dr. Raymond Boothe collection). |

|

| Allan Phillips posted #7 Blast Furnace, prior to startup (look how clean!). I took this picture near the base of #1 conveyor in summer of 1980. John Prejmak: It didn’t look that good for long. That whole north wall had to be replaced during the 1987 reline due to how badly it was corroded. Allan Phillips: John Prejmak Yeah, that’s where the slag pits were. That acid steam just ate right through the sheet metal, not to mention the water nozzles & pipes! Mickey Kostelnik: Long walk up that ramp, especially inspecting and replacing steps! Whole bunch of 50 foot oxygen and acetylene lines for burning. John Prejmak: Allan Phillips been there, done that. A few weeks before start up, I went up to the very top. I climbed on top of the bleeder crane shanty roof, just for the view. Allan Phillips: John Prejmak King of the mountain! Highest I went was the bleeder platform. James Torgeson shared A brand new Indiana Harbor #7. Michael Stilwell: Two cast houses, four tap holes? Sparrows Point's "L", commissioned in 1978, had them, and the "skip" belt, and three lockhoppers. Allan Phillips: Michael Stilwell Yes, 4 tapholes, numbered [counter]clockwise. They’d cast on opposite holes (1 & 3) for about 2 weeks, then switch to 2 & 4 while relining the trough & runners on 1 & 3. Peter M. DeStefano: 15k per day wasn't it? Allan Phillips: Peter M. DeStefano Started up at about 7500 per day, up to 9-10k a couple years in. Looking back, I think it was held back using 11 Battery coke. That was a failed experiment to use southern Illinois coal. If I recall right, the whole expansion was about $2 billion. I recall that furnace itself was at least $350M. Then 11 Battery, the Minorca mine, converting the Ryerson to a self-unloader & investments in the southern Illinois coal mines. I think 4BOF upgrades were in there too. I know it was at least a billion, but I might be thinking of New Carlisle on the $2 billion. I was involved in that project on the finance side too. 45 foot hearth! Sam Burkett: Koppers contract to Inland was 269 million that included the furnace and an 80 oven coke battery. Cost overruns took it to 450 million. Plus 2 1/2 years late. Sparrows point cost Koppers at least 2 million plus. These 2 lawsuits put Koppers engineering and construction out of the business. When I was there there were 8 floors of engineers and draftsman with 100 on each floor. [There are several more comments about Koppers problems.] Sam Burkett: Koppers casters left around 1977. their claim to fame was multiple strand casters. their moto was "keep on casting". Koppers is still alive. Their chem plants still supply coke by-products to make wolmanized lumber, aspirins, etc. The coke by products that Kopper got for free from the steel mills coke ovens was worth more than the coke. |

|

| Kevin A Heggi posted Inland steel from the LTV side of the canal. Michael Hansen: Looks like #4 AC Station .I worked there for few years. [Unfortunately, I don't know what an AC is.] J&L/LTV Steel Historical Memories posted Inland steel from the LTV side of the canal. Jessica Van Giana shared Phil Bridgman: To me, it's not LTV, it will always be Youngstown. Rich Paskash: I sure got to know my around LTV from engineering projects especially the BOF and the caster. Also did work the fcold mill and roll shops. My favorite 2 projects were the caster and No. 3 roll shop and 6 stand tandem mill. Now it's Cleveland Cliffs. |

|

| Dennis DeBruler commented on Kevin's post You must have been using a telephoto lens because there is quite a bit of distance between the light house, and this structure, |

|

| Kevin A Heggi posted Ore Bridges of Inland steel as seen from the YST/LTV side [The comments include a video of one of the energetic felling of one of them.] Dennis DeBruler: I fired up Google Earth and determined that the ore bridges disappeared between Oct 2018 and Oct 2019. I also noticed that the remnants of the blast furnaces down there were removed between Oct 2020 and May 2021. |

|

| Andrew Urbanski commented on Kevin's post Photo I took like 2006 I think |

|

| Kevin commented on Andrew's comment May 6, 2006 |

|

| Dennis DeBruler commented on Kevin's post I see the self-unloaders now unload at the north end of the peninsula. Google Earth May 2021. |

|

| Jim Prrfan posted Gary Clark photo . Edward L Ryerson (now out of service) Jim PRRFan collection [The comments discuss the odds that she will be put back in service. In Spring 2023, she is laid up in the Fraser Shipyard.] |

|

| Brian Gee posted This is some of Inland Steel in East Chicago, IN. There is an Inland Steel building in Chicago, well at there was one. I started right after UIC, and got my Master's at IIT when I was in Research & Development at Inland Steel. Paul Webb shared I worked at the downtown HQ in the Sales Dept. We shipped 700 trucks/day out of the mill then. |

|

| Justin Lehocy posted #7 |

|

| Joseph Bender posted Blast furnace number 7, eight tap holes I think it's got idk I was top gang. Clarence Melion: 7 Blast at Inland [Several comments specified 4 taps.] |

|

| Bill DuFault posted 2014 reline #7 blast furnace. Indiana Harbor EAST. Formally Inland Steel Corey Williams Big furnace that one! 😳 Biggest in North America, so I believe. Frank Newton Bill DuFault Spent 35 years there , many days on top that beast . Inland is east ,,,,,, J&L and old Youngstown , LTV depending on the era is west . And you are correct ,, I still call it Inland but Mittal did save it ,, not much left though , sad . |

|

| Aaron Metzger posted 4 furnace looking out at 7 furnace |

|

| 3D Satellite |

|

| 3D Satellite |

This must be #5.

#5 is in the upper-right corner of this image. We can see where blast furnaces #1-#4 were because their hot stoves are still standing. Why are the furnaces torn down, but the stoves are left standing? Do the stoves have more asbestos than a furnace?

How many plants did Inland have? I'm guessing that this mill was in Indiana.

|

| 3D Satellite |

|

| Satellite |

|

| Christopher Camalick posted, cropped Inland Steel's 100" Plate Mill finishing end caster bed for #5 shear. |

|

| Screenshot @ -0:08 Demolition of blast furnace at Arcelor Mittal East Chicago I believe this was #6. Oct 2018. |

|

| Paul Myers posted [Photo is taken in Youngstown Steel.] Coke train moving hoppers with No. 1 Blast Furnace and Open Hearths in the background. Mark Manufacturing. Inland Steel across the canal. (1923) |

|

| Kyle Hoover posted, cropped Arcelor Mittal East Chicago (Inland Steel) #7 continuous blast furnace. Largest continuous blast furnace in the western hemisphere. |

|

| Mike Smith posted Ore Field for #7 Blast Furnace with the Chicago skyline in the background. Frank Peters: 79 to 95 Dave Fisher: I remember when I first started working out there that was all lake, and they just filled it in |

Nick Ayres added two photos to Mike's post

|

| 1 Same stacker reclaimer, just a different angle. This was shortly after we got to sign the flag pole after the number 7 refurbishment around 2014. |

|

| 2 |

|

| Raymond Boothe posted Inland Steel Company (Now Cliffs Steel): Evening view of blast furnace No. 7 (Inland photo/Dr. Raymond Boothe collection). |

|

| Bill DuFault commented on Kyle's post Inside, from 2014 reline. |

John Hawkins commented on a post:

I worked the Plant #2 Blast Furnace Dept for most of my career at Mother Inland. Back in 89-91 Mittal took Mother Inland's #5 Furnace totally apart. You walked into the cast house to see 4 columns and the support ring.ALL the checker brick and combustion chamber brick was removed from #17, 18, and 19 stoves. They isolated the #20 "swing" stove from #5 as well.They replaced the old Blast Furnace Gas cleaning equipment with modern equipment. Removed the individual stove fans and installed two huge stove fans, a primary and backup to heat two stoves at once. This also required new air flow and gas flow mains and Instrumentation.The initial cost was something like $96 million, the board of directors said no, only $48 million, but we ended up spending around $92-93 million.We also had to convert everything to metric. So everyone went out and got a conversation Calculator.I remember the first day we started getting viable iron out of her and the helper takes an iron temp reading.All the White Hats starts punching Calculator buttons to get a reading they understood. 🤣The highline could only be accessed from the south end which came by #1 & #2 Blast Furnaces which came on line in 1907 and 1909.When I left in June of 2006, they would not allow full sized engines on the hiline to position cars, just a trackmobile.Furnaces #1 thru #4 were already torn down, which left #5 and #6 on the north end.In 1993-94, #7 Blast Furnace, out on the far end of the plant, got a Powder Coal grinder and injection system. #5 & #6 got an storage/ injection tower and they trucked powdered coal from #7 in specialized bulk tankers for us to use as well. That project was another $90 million.The #3 Sinter Plant was brand new in 1959 so for 25 or so years, nothing was done because it was too new, then cold bricket technology was the new deal and there was a period in the late 90s where the Sinter Plant was going to be shut down within 8 years, so the board refused to put any new money into the facility.When the Cold Bricket Technology failed to be viable, and our biggest customer, #7 Fce wanted MORE Sinter, the Board realized they had a 35+ year old Sinter plant and never put any real money into her, so we stockpiled Sinter, and dropped close to $50 million into her.In the early part of this century, China bought around 125 Blast Furnaces on line.4-5 were big ones like our #7, 10K tons / day, all the others were around were smaller ones like our #5 & #6. The reason, IMO China hosted the 06 Summer Olympics, you need steel for all that infrastructure. The cost of raw materials and steel went through the roof during that time, because China was buying all the raw materials they could get their hands on.When I moved to the Cold Mill in 2006, I found that most people didn't understand primary production. In group meetings, I bought up the new Furnaces in China and got no expression, no change nothing.When I noted we probably had around 40 Blast Furnaces operating in this country back then, some eyebrows quickly raised up.Looking at the Threads we know we have even less primary production today, in this country.This new technology may sound like the answer, but considering track record of what I've seen in the past decades....FWIW, at Mother Inland, #5 and #6 are gone, thus no need for Powdered Coal Injection tower or the highline.Only #3 Sinter Plant remains so far, to supply #7, but I've heard that it's days are numbered again.I hope that the powers to be are correct with these new technologies and long range decisions.

|

| Chad Yester posted Old #7 formerly inland steel east chicago, in. |

|

| Chad commented on his post |

|

| Ian Peery commented on Chad's post |

Is this building in the east or west side? I saw a nice sign in the video, but I presume I can't see it from a public road.

Dennis DeBruler

this is East, which used to be the old inland steel plant. Inland had red buildings Youngstown/LTV had black buildings.CJ Hopp

Thanks for the color code. That will help with future photos. |

| Frank Barbera posted Bad day at the 80”HSM Shot this from my crane cab. Not sure when this was. Maybe about 5 years ago.. Jeff Centanni: Is that where we cleaned that up and same thing happened? Frank Falardeau Jr.: Jeff, yup, 2 bars in a row that night. [Fortunately, this is posted in a public group so you can access the comments directly about other cobble stories.] Michael Scharnke shared |

|

| Frank Newton shared Inside of #7 BF ,,, CC Indiana Harbor East . 2014 Reline . John Seaman photo . [The comments include photos of the interiors of other blast furnaces.] Rob Van Wagnen: How thick is the refractory in one of them? Harold Sanscrainte: Rob Van Wagnen 3 feet thick. Calum Learn: 7 furnace has 4 tapholes. 2 active, one being rebuilt and one spare.: I am a refractory guy but FYI-the hearth from the centerline and down are carbon shapes (the hearth) and a coat of gunning castable covers the carbon so when they blow in the furnace, the atmosphere is very oxidizing until the oxygen leaves the furnace and it goes into a reducing atmosphere where smelting starts. Oxygen oxidizes the carbon so a sacrificial gunning mix covers the carbon to protect it from turning white like charcoal does (oxidation) in the BBQ. The man doing that gunite job did a very fine job. Who did that reline? Bill DuFault: Richard Allison Songer Richard Allison: That is a lot of working volume. No. 7 formerly known as Inland Madiline No.7 is the largest blast furnace in North America. Several in Japan and China are even larger. James A. Kenny: Richard Allison warren ohio , republic steel ..blast furnace is 500' high, Gary Indiana uss ...has a big one also ... Nick Hall: How longs a campaign on one of these blast furnaces? Richard Allison: Usually 10 years or more is a normal campaign. If a furnace is going to be retired, they will run it as long as it is safe. Furnace relines can be extended sometimes by furnace grouting. I have seen some furnaces with think linings in the bosh area over the tuyeres and the plates will be glowing red and instead of taking the furnace off, I have seen firehoses being fixed on any hot spots and they let the water flow off on the floor and to the ground. They do that on last campaigns or if orders are too good to shut down, they will go until it becomes a bad safety problem. I have seen some real bad situations like this on old furnaces. Calum Learn: #7 furnace has 4 tapholes. 2 active, one being rebuilt and one spare. |

I presume this BOF is in this location.

|

| Bill Staniec posted Scrap charging Inland BOF. |

|

| Bill Stainiec posted Inland's #7 Blast Furnace control room from the 80s. Kim Jeglum: Is that a Cherry RC? Cherry RC was released in 1995.. Dennis DeBruler shared #7 is the largest blast furnace operating in North America. https://maps.app.goo.gl/DsBCoK6wcU2dRZzK8 |

|

| Christopher Camalick posted in Inland Steel Company - Indiana Harbor Works, 1893-1998 When the 100" Plate Mill was a new original 90" |

|

| Thomas Grasha posted 100” Plate Mill Rope driven mill drive Plant 1 Riggers |

This is the other large, modern blast furnace that was built in North America. It has been torn down along with the rest of the Sparrrows Point works.

|

| John Sporik commented on Bill's post L furnace control room Sparrows Point |

Frank Newton posted eleven photos with the comment: "Had some Inland Steel pictures sent to me to add to my collection . Don't know who the photographer is though . Inland Plt.2 . #5&6 BF , Plt2 Highline, stockhouse and ore bridges . All are now gone , nothing but a field . PCI building still standing all alone now . Picture of #2 BOF which is no longer operational and due for the wrecking ball along with I think #2 Castor which sits on the end of the BOF . Hard telling with CC at the helm now."

|

| 1 Pulverized Coal Injection building , still standing . Everything behind it and to the right of it is gone. |

|

| 2 |

|

| 3 Frank Newton: Pulverized Coal Injection building , still standing . Everything behind it and to the right of it is gone. |

|

| Comments on Frank's third photo |

|

| 4 Frank Newton: #5 B/F |

|

| 5 |

|

| 6 |

|

| 7 Frank Newton: #2 BOF |

|

| 8 |

|

| 9 Frank Newton: #6 B/F: #5 B/F |

|

| 10 Frank Newton: #6 B/F |

|

| Andy Deegan posted I'm an engineer on the freighters on the Great Lakes. We spend a lot of time transporting ore to various mills. As I write this, we are anchored just off Indiana Harbor waiting on traffic at the dock to deliver ore to 7H. Chicago off in the distance as we wait our turn... Teddy Chakos: How late in the year will you be working? Andy Deegan: Teddy Chakos The locks at the Soo close on Jan 15th every year so we're almost done |

|

| Mike Delaney posted Tanker Polaris Indiana Harbor, she's heading to Whiting. Ryerson in background tipped with work being done on the prop seal. Mike Delaney posted Another photo of Indiana Harbor 1977. [The other was of the IH West side.] Sorry for another boat pic but it was my perspective. This is the Inland Steel side of the slip at the time. Tanker Polaris is headed for Whiting farther down the slip through the bridges to the refinery. Does show the folding ore bridges used for unloading their vessels. YS&T had similar unloading rigs for straight deck carriers but didn't span the entire width of the bins. |

Mike Delaney posted two photos with the comment: "Indiana harbor, 1976 shot from the Barker's rear deck. Ryerson came in after the Sykes. I think that either the PD or the EJ block in the background. They could unload 3 vessels at the same time with all those ore bridges. A lot of the furnaces and bridges are long gone on that side. We are unloading on the Youngstown Sheet & Tube side of the slip. To keep with the theme of no longer with us its all about the PD or EJ in the background so pay no attention to those two kinda still hanging around til this day."

AJ Breech: Great photo! The fleetmate in the background is the E. J. Block.

Rob Moffat: Love the Sykes in her Inland Steel and Bicentennial colors.

|

| 1 Steve Rowan shared |

|

| 2 |

|

| Dylan Cannell posted Suncoke Energy and Lakeshore Coal Handling with #7 in the background in East Chicago Pat McCon: The Sun Coke non-recovery coke plant is pretty cool. Dennis DeBruler: Pat McCon They just flare the manufactured gas? Facebook has been deleting my comments with a Google Maps URL as a violation of Community Standards. We shall see if this one survives. |

|

| Peter Fagan Jr. posted Inland/arcelormittal/cliffs 7 furnace [From the comments, this is evidently still the largest blast furnace in the Western hemisphere. It has four taps.] Brian Olson: That will probably be the last blast furnace to fall. cliffs is investing a good amount of money Matt Barnard: My first job in 1979 was helping to build this. The company I worked for was Koppers. Chicago Bridge and Iron actually erected the vessel. I was also there for the first reline,probably’84? I guess I’m not sure of that date. |

|

| John Coulter posted, cropped She sits idle like many others, once part of the great Inland Steel. I spent many of hours there from 2008-2015. A couple days ago I was at Indiana Harbor so I took a drive over to have a look and pay my respects. Plant 4 Electric furnace had many dedicated folks, it’s sad to see the old mill rusting away in East Chicago. |

|

| Comments |

|

| John Coulter commented on his post, cropped |

|

safe_image for boatnerd The Ryerson sets an ore cargo record during her maiden voyage from Escanaba, MI to Indiana Harbor. James Torgeson: Looks like some execs drove their cars right to the end of the slip! Frank Newton: James Torgeson I'm sure they did although during this time period all salaried employees had drive in passes while the hourly employees parked outside of the main plant in Inland owned parking lots and walked thru the clock house and then walked to their departments or waited outside of the clockhouse inside the main plant fencing for the next Cattle Car which then transported them to their departments . Cattle Cars were a modified semi trailer pulled with a semi truck on a designated route. They held about 75-100 employees. Many of the cattle cars were used in the Chicago Worlds fair or Exhibition in the early 30's . Inland bought them and used them as people movers like the Worlds Fair did . They lasted until about 1986 or so then everyone was issued a drive in pass and of course we went from 27,000 employees in the mid 70's to about 5000 in the late 80's so there was then plenty of parking inside the plant covering the 3 shifts . |

|

| Steven Kelsch posted 1987 East Chicago. sfk photos. History in our time. These two are still with us but not for much longer. [Steven took these photos from the boat he is on in the second photo.] Mark A. Popagain: 1987.... I was probably on #8 Ore Bridge unloading this boat like I did many times. I’m really surprised it hasn’t been scraped. I don’t know of any docks to unload it anymore and the cost of turning it into a self unloader was over $25 million back in 2000. Probably $30 to $35 mil today. I took the Dock Supervisor’s job in 1995. Also filled in for the Raw Materials Planner. I sat in on meetings with fleet Management and Raw Materials people who discussed changing the Ryerson over to a self unloader. But the cost was the biggest factor at the time. And we still had 4 ore bridges at the time to unload it. The Sykes I believe was converted back in 1975 when times financially were good. I worked for Inland Steel from 1974 till 2005. My whole career on the Ore Docks. James Torgeson shared |

|

| Dan Hughes posted Inland Steel Plant 3 East Chicago Indiana, looking west from Dickey Rd. John Hawkins: Started in Plt. #3. That's A Furnace in the background. Watched both A & B come down one Sunday morning. Howard Gene: The newest car I see is a 54. Larry Candilas posted Dickey Road, East Chicago at shift change a very, very long time ago. Mike Palmer: my dad worked at youngstown right across from inland there for 28 years. Bob Miller: Mike Palmer actually Inland was on both sides of the road at that location. YST was across the canal, and also on both sides of Dickey Road. Bob Miller: Mike Palmer in the 70's they built a Cline Ave. extension, over the railroad and canal, and we didn't use Dickey Road anymore. Was a life saver. I haven't been there since 1989 either. Curt Zehner: I remember that giant forge hammering away down the street, shaking the street as you drove by. Mark Goodrich: Curt Zehner Indiana Forge. That was pretty wild wasn't it. Michael Taylor: Mark Goodrich did that become Standard Forge? Mark Goodrich: Michael Taylor I believe that was on the other side of Dickey-huge place. Indiana was smaller but you would get hung up at the light turning right following 912 through "The Harbor". |

|

| Mike Lynch commented on Dan's post |

Kevin A Heggi posted two photos with the comment: "Inland Steel 1943."

|

| 1 Bob Lalich: The open hearth shop just right of center is amazing! |

|

| 2 Bob Lalich: An unusual roundhouse on the left. The lead to the turntable passed through the structure. |

Mike Delaney posted seven photos with the comment: "Some photos from Inland Steel 1893 to 1943, 60 pages."

|

| 1 |

|

| 2 James Torgeson: Lots of ore boat namesakes! |

|

| 4 |

|

| 5 James Torgeson: EMD SW1 |

|

| 6 |

|

| Steve Herrmann posted New cone going on the furnace vessel at the old inland plant. [There are some comments about "topcone cooling."] Javier Garza: That's one (top section)out of three. Place them in position as a charging crane operator. |

This photo provides some scale.

|

| Jason Murzyn commented on Steve's post Believe I saw that getting delivered. |

|

| Dale Wendell posted The old Inland Steel blast furnace facilities that was merged into Indiana Harbor facilities from Whiting Park. [BF #7] |

|

| One of 13 photos posted by Jim Langreder 4 sub station and 3 pump house at cleveland-ciffs(inland steel) IHE Plant 1 |

|

| Tom Cera posted Cliffs #7 Blast Furnace under construction in 1978.. #11 Coke Battery is about to be commissioned. #4 BOF is at the right. View looking east from Whiting Park in Whiting Indiana. |

|

| Frank Newton posted Frank Newton shared Steve Herrmann: Wish they woulda made the “furnace isle” 70’ wide too. It was always supper tight trying to get forklifts around on the furnace floor! |

|

| Tom Cera posted Inland Steel #11 Coke Battery, 1978 Michael J Mikula: Before the hood over the coke side was put up. David Payo: That hood was all stainless steel wasn't it? |

|

| Tom Cera posted Inland Steel #11 Preheat Building and Coke Battery, 1978 |

I think this is what the preheat building looks like today.

|

| 3D Satellite |

|

| Bob Foster posted Ore field construction at Indiana Harbor, Inland Steel c.1917 |

|

| Bob commented in his post |

They pounded thousands of posts in the ground and backfilled.

|

| Bob Foster posted I believe this is the construction of Open Hearth no. 2 buildings at Inland Steel c.1937 Mike Vannatta: Notice the stiff leg derricks on rails ! Old school steel erecting at its peak of technology!! James Musser: There is a book called Steel Giants that is chock full of these construction photos - half is of Inland and the other half USS Gary. If you are interested. |

|

| safe_image for Trebor Flickr Inland Steel Plt.#3 "C" battery Doesn't take the planet long to make a return . Notice trees growing on top of Battery . Went there on occasion to look for tools, explore a tad or for parts to take to Inlands Plt #2 , 6 thru 10 batteries . Ivano Cipolla: I still work at the original Inland steel plant in Chicago Heights, a rail rerolling mill still making fence posts out of old railroad tracks now called Chicago Heights steel. Steven Berwald: What a shame what happened to plants 1 and 3. Ron Church: I salvaged electrical switchgear from there for use at plant two. Nick Shultz: Was always a great time exploring plant 3 when I was out there. Frank Newton: Nick Shultz And Plant #1 with the 100" plate mill still there . Did that at 2am with just a flashlight . Kind of eerie . You could almost sense a couple of generations of workers of past times when you just sat there and listened . Strange feeling . Nick Shultz: Frank Newton without a doubt. Plant 1 and 3 are crazy. Even more crazy is to think, ltv side included for the most part, all that's left operational is plt 2. [The are some comments about the inferiority of the coal that came from their coal mine at Sesser, IL.] |

|

| Frank Newton: Plt.#2, Plt.#1,Plt.#3 then Plt.#4 furthest from the lake. Dennis DeBruler Frank Newton It looks like plant #4 is still active. |

|

| Lou Gerard posted Inland Steel's Clarence B. Randall unloading at Inland, Indiana Harbor. 1974. Joseph Kaemerer: That looks like Plant #3 ore docks. John Hawkins: Yeah, that's 3 AC in the background. She was a smaller boat that could make through the two narrow spots in the canal around Plt #1 to get down to Plant #3. |

|

| Lori Wagner Vadas posted The last coil produced on #5 Galvanize Line. Formerly Inland Steel #3 Cold Strip West. George Ribar: No take up tower, I worked on the # 6 line hot dip Galvanize line at Gary Works 60 wide with a galvaneal furnace. The zink pot froze up and that was the end of the line |

%20Steel%20Mill%20Pictorial%20_%20The%20last%20coil%20produced%20on%20%235%20Galvanize%20Line%20_%20Faceboo.png) |

| Comments on Lori's post |

|

| Voljin Darkspear posted 80 Hot Strip mill IHE…. To dangerous to go down and start burning cobble just yet |

|

| 1 of 5 photos posted by Rick Catania Here are some drone aerial photos a friend of mine, who goes by the name of Phoenix Mythology, took recently of what is left of the Electric Furnace in Plt 4. [I wonder how the new Cline Ave. toll road is doing.] Frank Newton shared Borrowed from another site . This is what's left of the EAF at the old Inland Steel Plant 4 site . On again - off again production run for the past 20 years . ArcelorMittal eventually just let it sit and soon became parted out and used as an adventure area for urban explorers . Cleveland Cliffs sold it to an investment group but haven't announced any plans yet for the land . Time moves on . Tom McKeon: Supposed to be a Data Center going in , just like they did by the Old State Line Power . They need the Power & water for cooling . Second rumor is the General Iron shreader that Chicago won't give Permits to is going in The US Steel building on Dickey Rd across from Amigo Oil. Something is better than nothing . |

|

| Steve Resler posted Here's what's left of the Electric Furnace/Billet Caster in Plant #4. You can see the DRI truck ramp in the far left of the photo. Picture taken November 6th 2022... Diane Adkins: So sad to see. 12” bar mill demolished too. Jim Gogolak: DRI was supposed to be the savior of the electric furnace. What happened? Bill Cravens: Jim Gogolak. Increased demand ran the price of DRI up. Plus making it used nat gas, which became more expensive. Didn't pan out. Linda Wagman: Is anything left at Inland?? James Bock: Linda Wagman 7 bf, 4 bof 1 caster3 cold strip east , 80 inch John R. Szabo: Don’t forget plant one machine shop. James Torgeson shared |

Jim Langreder posted five photos with the comment: "Sinter Plant...closed down a few months ago."

Russell Goodwin: So what are they doing for sinters for the blast furnace?

Robert Stephen: Russell Goodwin HBI briquettes

Frank Newton shared with the comment: "Just recently shut down . Old Inland Steel Plt. 2 now Cleveland Cliffs IHE Sinter Plant . Time and technology moves on . Thanks to Jim Langreder for the photos ."

John Hughes: That's the East side. West side sinter plant has been down for about 14-15 years.

Allan Phillips: John Hughes Is this the one located down by where #6BF was? I worked there as an engineer for a few years.

John Hughes: Allan Phillips i believe so. 5& 6 BF were both finally demolished about 4 years ago. I was lucky enough to be working right across the canal from them when they went down. It was loud!

Both 5&6 were on the east side along with 7. West side had 1, 2, 3, and 4.

Mark Scarsella: What does IHE do with there scale if they don’t have a sinter plant ?

Frank Newton: Mark Scarsella Must have a buyer or they are stock piling it somewhere on the property . Don't know if they are shipping the fines to Cliffs new HBI briquette plant in Ohio for use there in making briquettes .

Bret Yelachich: Spent many hours at that one, now I’m at the sinter plant in burns harbor. [So C-C still has a plant in the area.]

Matthew James Siddons posted two photos with the comment: "Taken when I was railfaning Chicago back in 2009 ? If understood right from another post railfans get bothered here now."

Scott Irwin: Those were most likely headed for Riverdale AKA Acme steel the spacer cars were because of the Bridges they had to cross as to spread out the wight of the bottles. I ran the locomotive that brought them to the melt shop / BOF

|

| 1 |

|

| 2 |

|

| Anonymous participant posted Record tonnage at 7bf [I preseume this is #7 at this plant.] |

|

| 10:25 video @ 6:39 (Source) [We soon see that the bottle cars are loaded.] |

|

| safe_image for 0:40 video Mark Curtis: I was there watching, sad ending. I actually started my Inland career in almost this exact location, which was 2 open Hearth. Frenk Hewton shared ArcelorMittal or Inland Steel as many still call it . Indiana Harbor East , #2 BOF last cast . 2017 Keith R Phelps: Turret bearing quit. |

10 photos including the "blue bridge" from a locomotive cab A comment indicates that BFs #5 and #6 were torn down in 2018. The photos show the stoves are still standing.

Flickr photo of the ruins of the old part (source)

0:24 video of "demo of Inland steel #6 blast face" (The bang is at 0:07.)

Keith R Phelps: 6 was a piece of crap. Electric mud gun, pneumatic drill, no slag tilter, but 5 was a 🍑

1:55 video of last bar to run through Plant 4 (2015)

Ed Hadt: That mill started in 1969 and was paid for in 1976 when I started working at this 12" bar mill as an mechanical apprentice,it was a great place to work a lot of good people and memories.

Joseph Kaemerer: Just like the 100” plate mill, they ran it into the ground and milked every last dime out of her.

I worked there asa Mill Mrchanic Erwin

ReplyDeleteBicher 0815 for some 43 / years beyfore I retired Under Joe Griffin

My dad, Vic Pantea, worked in Engineering Dept from ‘52 to ‘86. He started working there during WW2 while still at old ECW HS and lived a short walk away on Hemlock. His step dad worked at one of the Open Hearths. I worked summers for 3 years ‘ 71- ‘73. First two at #3 Cold Strip last at Production control. One of my dad’s last big projects was the construction of Madeline #7 Blast Furnace. This blog certainly brings back a lot of memories

ReplyDelete