(

Satellite)

|

lcra

This is the furthest upstream of the six Highland Lakes dams on the Colorado River in Texas. This dam and Travis Dam are the two storage dams for water supply and flood control. "In 2021, LCRA completed a $51.1 million project to upgrade and strengthen the floodgates, hoists and other facilities at the dam." "145.5 feet [41.3m] high, 10,988 feet [2249m] long" It has 37 flood gates with a total discharge capacity of 348kcfs. Top of dam: 1,025.5' Spillway: 1020.35' Full: 1020' It holds 880,356 acre-feed when full. [I think this is the first big storage dam I've seen that doesn't have a conservation pool that is lower than the flood pool.] |

The maximum design water level is 1024'. The historic high was 1021.4' on Dec 20, 1991, and the 100-year flood is 1021'. "Currently, Lake Buchanan is operated at two normal pool levels, 1,018 and 1,020 feet above mean sea level, for May-October and November-April, respectively." [

twdb]

|

| [I lost the reference for this photo] |

July 14, 2025 Flood

As of July 15, 2025

Historic Levels:

They first opened two gates in the middle spillway.

|

kxan

"Floods force Buchanan Dam to open flood gates for first time in years" [Since 2019.] |

Those gates must be some of the small gates.

Four gates opened is the highest number that I've seen so far.

|

LCRA posted 0:36 video

Coordinated floodgate operations across the Highland Lakes system. This drone footage, shot over the past few days, shows floodgates at Buchanan Dam, Wirtz Dam and Starcke Dam, as LCRA manages water from recent flooding in Central Texas. Lakes Buchanan and Travis are designed to fill during major weather events, and another reason why staying flood-ready is crucial in Flash Flood Alley. Our thoughts remain with those affected by this devastating flood. |

|

Meteorologist Avery Tomasco posted

Lake Buchanan is now at its highest elevation in 6 years Lake Travis is now at its highest elevation since August 2020 Both still rising this morning. Unbelievable volume of water entering the system over the last 10 days |

|

Brandon Butcher posted

MORE SOUTH TEXAS FLOODING - Evacuations are ongoing on the San Saba River, which will crest tonight close to the level of last time, but the heaviest rains have not concentrated in the Guadalupe River basin this time. |

It is interesting that they open some of the gates all of the way instead of all of the gates some of the way. Obviously, all of the gates have dedicated lift machinery so it would be easy to partially open all of the gates

%20Video%20_%20Facebook.png) |

Hill Country Scanner posted 0:31 video

Lake Buchanan floodgate operations July 14, 2025 courtesy share with Hill Country Scanner |

A Buchanan Dam gate structure is in the right background.

|

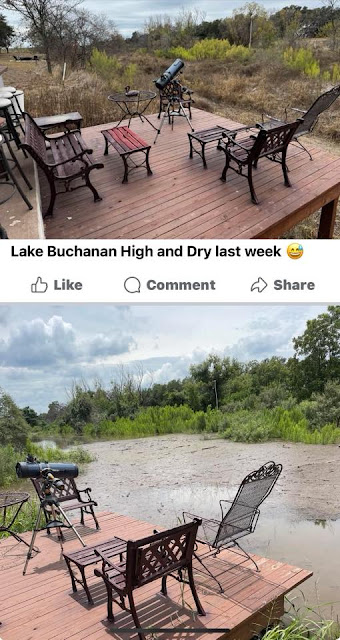

Valentine Lakeside posted

This is below Buchanan Dam, where four gates are flowing into Inks Lake. That water will make its way to LBJ. |

On the right side of the above video we can see a dock under water.

I wonder what type of obstruction in the river causes this turbulence.

|

| Same Video |

.jpg) |

Guy Hood commented on a post

I waited years to see this day! Please don’t let the water go away again! |

%20Railroads.png)

%20Facebook%20and%204%20more%20pages%20-%20Personal%20-%20Microsoft%E2%80%8B%20Edge.png)

%20Video%20_%20Facebook.png)

.jpg)

%20Facebook%20and%204%20more%20pages%20-%20Personal%20-%20Microsoft%E2%80%8B%20Edge.png)

.jpg)

.jpg)