(American-Rails)

If you look at an Indiana road map that includes railroads, you will see a track along the western boarder. That is NOT the Chicago & Western Indiana (C&WI)! In fact, it is two other railroads. The northern part is NS/NYC/Kankakee, Danville, Cario/Chicago, Indiana & Southern, and the southern part is CSX/MoPac/L&N/Chicago & Eastern Illinois.

|

| Wikipedia |

Brown also founded the Belt Railway of Chicago (BRC) in 1883 by using the charters of the original three railroads to build a branch west at 74th Street that turns north just before Cicero Avenue and then goes north to the Chicago, Milwaukee and St. Paul Railway at Cragin. Another BRC ancestor branch was built east of where C&WI's eastern mainline curved from due east to southeast. This is why a 1920 C&WI map (below) includes the Belt's routes. (Wikipedia)

Some of the trunk railroads that connected with the C&WI bought the terminal railroad so that the C&WI could build the Dearborn Station and the C&WI would provide access for the passenger trains. The station was completed in 1885 and closed in 1971 when Amtrak was formed. During the 1930's and 40's, C&WI provided commuter service to Dolton. Metra is investigating the resumption of that commuter service. The former C&WI tracks have already been connected to the former Pennsy tracks at the 21st Street Crossing to support the SouthWest Service over the former Wabash tracks.

IRM Strahorn Library posted two images with the comment:

Chicago & Western Indiana #210 2-6-0. We believe this locomotive is readying to couple onto its own commuter train from Dearborn Station to Dolton. Such commuter service continued until July 26, 1963.For more on these C&WI Moguls please see:From Wikipedia:"The Chicago and Western Indiana Railroad (reporting mark CWI) was the owner of Dearborn Station in Chicago and the trackage leading to it. It was owned equally by five of the railroads using it to reach the terminal, and kept those companies from needing their own lines into the city. With the closure of Dearborn Station in 1971 and the Calumet steel mills in 1985, the railroad was gradually downgraded until 1994 when it became a subsidiary of the Union Pacific Corporation."An excellent source for further reading about the C&WI is Ogorek, Cynthia; Molony, Bill (2016). Images of Rail: Chicago & Western Indiana. Arcadia Publishing. ISBN 9781467116688, which is also available at the Strahorn Library.Larson Collection, Illinois Short Lines, Volume 1, Illinois Railway Museum Strahorn Library.The Strahorn Library houses thousands of books, tens of thousands of periodicals and more than a hundred thousand photographs, all centering on the subject of trains and railroading and all held to support research and scholarship into the railroad history of the United States.The Strahorn Library is at 118 E. Washington Street in Marengo, Illinois. It is normally open from 10AM to 2:30PM on Wednesdays and visitors are welcome. For those unable to visit, we can provide access to our collections via telephone (815-568-1060), e-mail (strahorn@irm.org), or online catalog (librarycat.org/lib/IRMStrahornLibrary).All materials are available for non-commercial purposes, and according to the “fair use” provision of the U.S. Copyright Law which permits use of copyrighted material for criticism, comment, news reporting, teaching, scholarship and research.

IRM Strahorn Library shared

|

| 1 |

|

| 2 |

Wikipedia provides the following list of towers starting from the north:

12th Street tower, 15th Street tower, 16th Street tower, 21st Street tower, 40th Street tower, 47th Street tower, Ford Street tower (59th Street), 74th Street tower, 81st Street tower, Oakdale (later remote controlled by 81st Street), Pullman Junction, South Deering (112th St., later remote controlled from Main Line Drawbridge), Main Line Drawbridge and the famous State Line tower, which was North America's largest interlocking controlled by strong-arm mechanical levers. Pullman Junction was not a conventional interlocked junction, although there was a small interlocking machine for the signals protecting the C&WI-BRC junction there. The crossings were protected by gates and tilting targets. All trains were required to stop. Switchtenders were located at Dearborn Station, 31st Street, 80th Street and Pullman Junction.

Centralized traffic control was introduced in 1973, combining 40th Street and 47th Street, later 59th Street and 74th Street, a four-tower combination was operated by the train dispatcher located at 47th Street tower after their relocation from Dearborn station.

|

| 1920 Map from the Indiana Historical Society |

A higher resolution copy. Click this image then right-click the new image to save the image. Then you can use your favorite photo viewer to pan and scan the image.

Update:

Bill Swislow posted two images.

A tidbit from a posting concerning the C&WI after its route parallel to the NKP to the state line was abandoned:

Bob Lalich The former mainline to State Line Tower is still in place between 81st St and 110th St. It belongs to NS now. NS also shifted the ex-NKP main tracks to the former C&WI RoW between 130th St and Burnham.

|

| 1920 Map from the Indiana Historical Society |

- 22nd Street or Canalport Yard: team tracks for all of the owners

- 37th Street Yard: Chicago & Eastern Illinois

- 40th Street Yard: Wabash

- 47th Street Yard: Erie leased yard tracks and C&WI had an adjacent coach yard

Update:

|

| 1906 The Official Railway Guide: Freight Service, Page 76 A high resolution copy of just the map via American-Rails |

|

| Bill Molony posted Atchison, Topeka & Santa Fe Railway 4-6-2 Pacific-type #3419, drifting along the Chicago & Western Indiana Railroad's tracks towards the 12th Street Tower and Dearborn Station on the morning of May 30, 1934 with the 17 cars of train #6, The Ranger. The 3419 was one of 50 3400 Class 4-6-2's built for the Santa Fe by the Baldwin Locomotive Works between 1919 and 1924. Bob Lalich Very interesting photo! The reefers are spotted on a Wabash track. The platform was covered by a structure in later years. No cars spotted at the C&EI freight house on the right. Stuart Pearson Santa Fe's 4-6-2's, and many other Western Railroads Pacifics were often time bigger than Eastern RR's Hudson's (4-6-4's) due to clearance problems in the East. |

|

| Bill Molony posted Chicago & Western Indiana class K-1 0-6-0 switch engine #233, switching a heavyweight Wabash chair car at Dearborn Station in February of 1949. The 233 was built by Alco in 1913.Bob Lalich This is 21st St. Judging by the engineer's position, the locomotive is pulling the consist back to the coach yard at 51st St. |

|

| Bill Molony posted

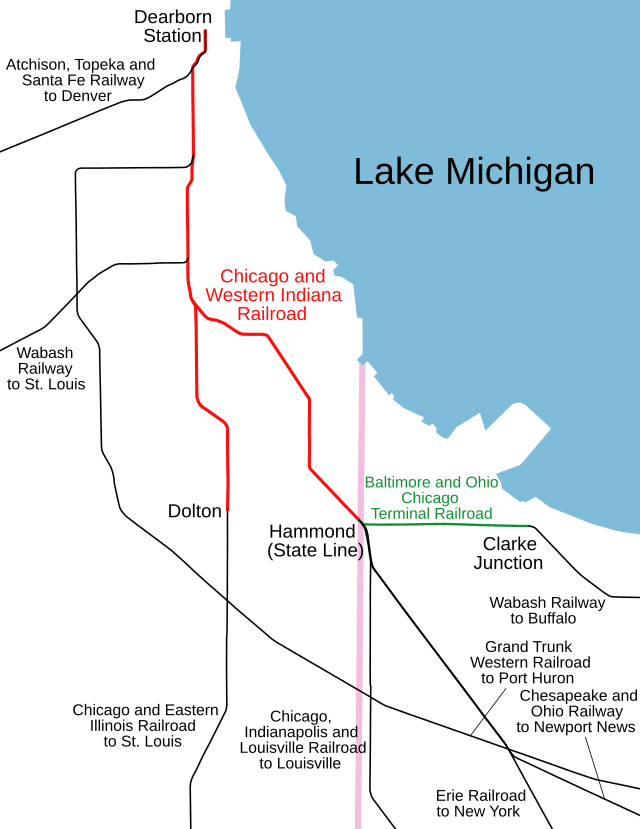

This map shows (in red) the lines of the Chicago & Western Indiana Railroad Company, and its numerous connections, as they were in 1916, 100 years ago.

At that time, the C&WI and Dearborn Station hosted the passenger trains of the following railroads:Atchison, Topeka & Santa Fe Chicago & Eastern Illinois Chicago Indianapolis & Louisville Chesapeake & Ohio of Indiana Erie Grand Trunk Western Wabash Bill Molony reposted Bill Molony reposted Bill Nimmo at the ends of the orange i am trying to figure out what roads it leads into. hard to read the bottom one even if enlarge. the one of the right bottom looks like it goes into the nickel plate or the erie. Bill Molony The line going straight south was the connection with the Chicago & Eastern Illinois at Dolton. The line to the lower right was the connection with the Wabash, the Erie, the Chicago, Indianapolis & Louisville and the Chesapeake & Ohio of Indiana at the Illinois-Indiana state line. Bill Molony reposted This original map of the Chicago & Western Indiana Railroad is from 1917. The C&WI was owned by the Chicago & Eastern Illinois, the Chicago, Indianapolis & Louisville [Monon], the Chicago & Erie, the Grand Trunk Western, and the Wabash, with each of the five companies owning 20 percent.Ean Kahn-Treras hmmmm is Hammond Junction the implied name for the 87th Street split between the two legs of the CWI, or something else? Hard to tell on the map exactly where they are referring to.Bob Lalich Hammond Junction was an interlocking where the line to Dolton split with the line to Hammond prior to elevation. The layout was drastically modified with the elevation project, after which the passenger tracks split at 81st St, and the freight tracks split at 80th St.Ean Kahn-Treras was the rock island ever at grade just to the north as well?David DaruszkaDavid and 3 others manage the membership, moderators, settings, and posts for Chicago Railroad Historians. Chicago track elevation timeline: https://www.chicagorailfan.com/elevate.html |

|

| Paul Petraitis commented on one of Bill's postings |

|

| Paul Petraitis answered a question about the Indian Boundary Line on one of Bill's postings

One of the only land concessions the US won after the stalemate that was the War Of 1812...part of the Treaty of St. Louis (1815 ?) it was surveyed over the winter of 1817/1818 from the mouth of the Little Calumet River near 92nd St...it bisects Lake calumet, appears on the ground at 127th and Wentworth and further south as George Brenan Highway parallel to I-57 south of Blue Island. George Brenan was the Roseland area's first historian and a contributing member of the Illinois Historical Society...also our neighborhoods first high school principal. He published in 1918 "The Wonder Of The Dunes". This is the southern IBL, there's a north one too that starts 10 miles north of the Chicago River and winds its way SW as well bisecting Bolingbrook. Since it precedes Illinois statehood (1818) its on most legal property descriptions.

|

|

| 1 |

|

| 2 Bill Swislow posted Ian M Contreras: Huh. Interesting that they show the branch towards the former Grant Works in Cicero way up at the north end of the Belt as being BRC trackage. I had always assumed that was BOCT property. Paul Arden: Not sure of the exact arrangements, but I believe the BRC had / maybe still has trackage rights to serve a couple of industries on the Cicero Branch. As late as 2000, occasionally, the BRC would ask to go down there (when I was a Dispatcher for CSX/BOCT). I think almost all the industries are gone now. |

|

| Bill Molony posted Chicago & Illinois Western Railroad Alco HH660 end-cab switch engine #1. This locomotive was powered by a McIntosh & Seymour 531-series 6-cylinder prime mover rated at 600 horsepower, and rode on Blunt trucks. |

A tidbit from a posting concerning the C&WI after its route parallel to the NKP to the state line was abandoned:

Bob Lalich The former mainline to State Line Tower is still in place between 81st St and 110th St. It belongs to NS now. NS also shifted the ex-NKP main tracks to the former C&WI RoW between 130th St and Burnham.

%2Bworking.png)