RFID (Radio-Frequency IDentification) technology allowed the railroad industry to try again to automate identification. RFID technology has been in development for decades to allow many industries --- freight trucks/containers, retail, libraries, healthcare --- to automate inventory (and pets) tracking. An RFID Tag is mounted on each object to be tracked, and readers are installed at strategic locations. For example, our library now has readers that you must walk through at each of the exists as well as to checkout stacks of books. An important aspect of the tags is that they get the power they need to respond from the beam the reader sends to communicate with the tag. The development of the technology keeps shrinking and reducing the cost of the tags so that they can be more ubiquitous. By the early 1990s, the industry could afford to put a 3 by 10 inch tag on each freight car, container, locomotive, MoW vehicle, etc. In this application, not having a battery was an issue of maintenance rather than size or cost. Since the end of 1994, all items are to be tagged. That includes over 1.2 million cars and 22,000 locomotives. (Trains) The tags are supposed to be on the left end of each side. As an aside, the RFID industry's goal is to make the tags cheap enough to replace the UPC Bar Code. That is, all items in all stores can be read by RFID scanners. Note that scanners can be used for inventory counting as well as checkout.

I don't remember seeing tags on modern equipment so I looked at some of the pictures I took of a mixed freight on April 27, 2015. At first, it was hard to find them. But then it became rather easy to find them. I added a red rectangle around the tags.

(For future reference, a link to freight car history.)

Update:

|

| Mark Hinsdale posted Photo is from July 1977, at Dolton. Thomas Kidd MP 3232 is Northbound and the other is Southbound.Jim Sinclair Mark, not only is this a great capture with lots of human interest, you also captured the ACI scanner, which is seldom seen in older images. |

|

| Steve Forrest posted The "Memphis Big Boy" derrick based out of Johnston Yard in Memphis back in Oct 1973. Kodachrome by Steve Forrest. Dennis DeBruler That is the best preserved ACI marking that I have seen. |

|

| Digitally Zoomed |

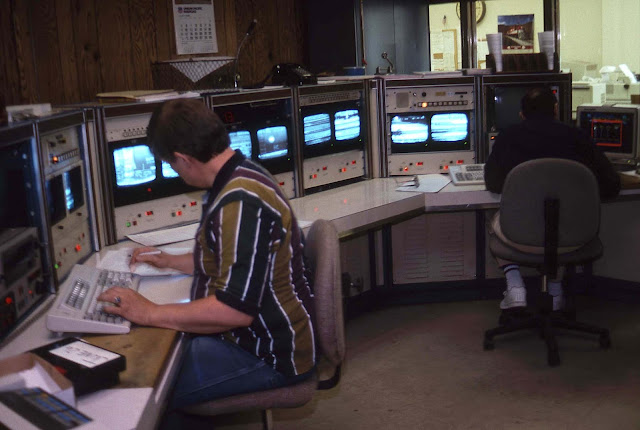

Sean Graham-White posted two photos with the comment: "Before AEI, the BRC had cameras along primary entrances/exits to Clearing Yard to record reporting marks of each train. Clerks would verify them to train reports that had been advanced from other railroads to ensure accurate car reporting and billing. Bedford Park, IL 7/1/95"

Richard Brunke: AEI was being used/tested/perfected long before 1985...try the 70's.

Sean Graham-White: Richard Brunke You are thinking of ACI - similar to a barcode, that was applied to the side of rolling stock. Photo was taken in 1995.

James Petrusek: When I worked there (2015-2017) we still had cameras to monitor near each AEI installation. The clerks would often still review the video to verify cars. Despite RFID, wheel sensors and a sonar presence detector, there still were errors. RFID tags would fall off, metal shavings and grease from flange lubricators would cause havoc with wheel detectors, or a good rain or worse, ice and snow would foul the presence detector horns. We had to do routine maintenance and lots of snow duty to keep them working.

Our biggest headache would be ballast or track crews might use a machine and break off the wheel detectors! Very frustrating.

Joseph Tuch Santucci: They used to have clerks at the entrances to the east and west receiving yards who did this the old fashioned way with paper and pencil. The conductors gave the clerks their trains’ waybills. The clerks would place the hand written lists and waybills into cylindrical containers and place them into the vacuum tube where they were zipped to the main office building just below the humps. These clerk jobs were eliminated with the cameras that were installed. Progress.

|

| 1 |

|

| 2 |

No comments:

Post a Comment