1929 Bridge (Bridge Hunter, Historic Bridges)

2011 Bridge (Bridge Hunter)

At least a visual arch was replaced by an arch, but we lost another truss bridge.

|

| NYDOT |

|

| Boston Public Library, CC BY Lake Champlain Bridge, connecting New York State and Vermont at the "Narrows" from Chimney Point, Vt., to Crown Point, N. Y. |

|

| Doug Kerr Flickr 2007 Photo, CC BY-SA Crown Point Bridge over Lake Champlain |

|

| NYDOT |

|

| Flatiron |

|

| info-boards |

|

| Flatiron |

The center span was lifted into place without a concrete deck. This was done to limit the weight of the lift to just the structural steel components of the structure. To expedite the deck construction on the arch, precast concrete panels were used for both the roadway surface and the sidewalks, which are located on the outside of the arch. These panels were staged on barges, lifted by crane to one end of the arch and moved into position using rollers. After the arch was loaded with the weight of the precast panels, the final VT and NY approach deck pours were progressed. The transverse space between each precast deck and sidewalk panel was filled with concrete in a series of small transverse closure pours. With all of the transverse closure pours completed and cured, the precast concrete deck panel system was post-tensioned. [construction]

A main feature of the new bridge is the zinc metalized corrosion protection that will be applied to the structural steel. The new bridge one of the largest in North America to be completely zinc metallized. [Flatiron]That is, the bridge is made with galvanized steel. I read a book about rust, and the author was rather adamant that galvanized steel should be used for bridges because the initial cost would soon be paid off by the reduced maintenance, e.g. no painting.

(new window)

While inspecting major repair work that was underway in October, 2009, the engineers found such serious problems in the piers that on October 16, 2009, they did an emergency closure at 1:30pm without advance warning to the public, causing major traffic issues. [story; Yannotti, Slide 33] Given that the road detour route was 84 miles and 2 hours, the public was outraged. Meetings were held and heads were scratched including temporary pier repairs and various temporary bridge designs until they decided to build a temporary free ferry service at the bridge. [Slide 55] Design approval for the new ferry service wasn't granted until November 11. [Slide 60] The new service opened February 1, 2010. [story]

Because falsework was used to construct the old bridge, it was decided it would be removed with "energetic felling." [Slide 70]

(new window) Skip to 0:39 for the big bang. The reason the video is so long after the explosions is that waves created by the steel falling into the water reach the ice in the foreground and break it up. It is worth waiting to see.

(new window) Just the explosion in slow motion

While the steel and piers of the old bridge were being removed, a normal year long design process was completed in 10 weeks in 2010 by HNTB. The good news was that they could use the existing approach since the old bridge was not using it. This saved a lot of environment impact study time. (Because of historic forts etc. that were very close to the existing alignment, any movement of the alignment had significant issues.)

|

| HNTB |

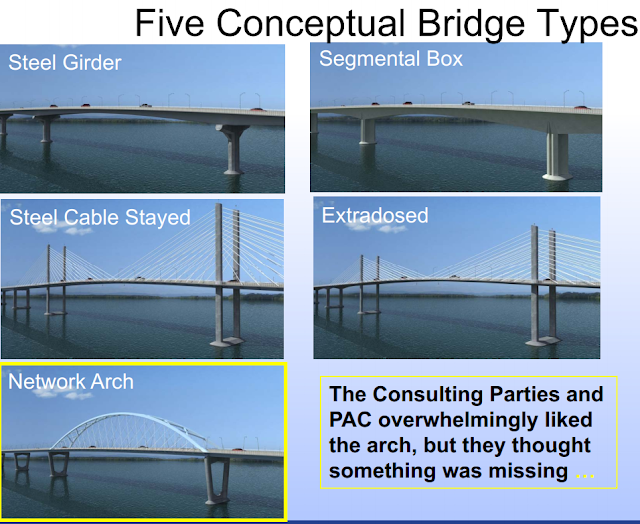

If we look at the initial concept for the network arch bridge below, we see how the V structures did improve the ascetics of the bridge for those used to seeing the deep truss arch bridge. (And for those who haven't. Personally, I think the modified design looks a lot better.) We also see how the design of the pier was changed so that the same concrete pour form could be used for the top of all of the piers and the height is determined simply by adjusting the length of the stem of the pier.

|

| Yannotti, Slide 87 |

26:47 video

No comments:

Post a Comment