|

| Satellite |

|

| Fall 2017 |

|

| Facebook from cbc.ca-20180114 |

An engineering report received by the province in July, but not public until September said there were three reasons for the bridge's failure.

The province reiterated in the fall that neither cold temperatures nor wind were to blame for the bridge's failure. It also stressed that overloading — not any kind of flaw — caused the bolts to break. [cbc.ca-20170110]

- The design of the shoe plate and its flexibility

- A lack of rotation in a bearing that was constructed

- Improperly tightened bolts attaching the girder to the shoe plate [they were (way) too loose]

|

| Ted Gregory posted, cropped Eastbound CP crosses the Nipigon River a few weeks ago. Behind it is the brand new (2015) Trans-Canada Highway bridge. But only 2 lanes are open, as the other half of the bridge is still under construction. I Believe the second structure has been delayed after the pictured highway structure was shutdown. On January 16, 2016, winter storm gales snapped an expansion joint that led to one half of the bridge being raised 24". Not 2.4, 24. Last I heard, no formal determination of cause has been made. Ted Gregory shared Dennis DeBruler - The design of the shoe plate and its flexibility - A lack of rotation in a bearing that was constructed - Improperly tightened bolts attaching the girder to the shoe plate [they were (way) too loose] https://industrialscenery.blogspot.com/.../nipigon-river... |

|

| Screenshot from the first video in GlobalNews-20160111 |

The spans are 820 feet (250 meter), but I have not found the height of the towers.

|

| Canam Bridges This page also has a video of drone footage of the construction. |

As to why there is only one road (and bridge) across Canada, Ted Gregory commented in a posting:

The Canadian Pacific transcon is immediately next to the Highway bridge.When CP built their line across Canada, the stretch across the north shore of Lake Superior was the most difficult to build.CP has 5 mountain crossings and this was the most difficult!!He later posted a link about the CP construction.

There's alot of profile and massive granite outcroppings on the north shore of Lake Superior.

Another factor is the weather. The storms are ferocious. Infact it was during a winter storm that the connecting pin snapped. The Nipigon River handles a tremendous amount of water with alot of momentum. In its 30 mile length, 4 dams exist for hydroelectric power. It is the only outlet for Lake Nipigon, the largest lake in Ontario.There's alot of profile and massive granite outcroppings on the north shore of Lake Superior. Another factor is the weather. The storms are ferocious. Infact it was during a winter storm that the connecting pin snapped. The Nipigon River handles a tremendous amount of water with alot of momentum. In its 30 mile length, 4 dams exist for hydroelectric power. It is the only outlet for Lake Nipigon, the largest lake in Ontario.

Some of the articles about the bridge mentioned that the province has decided that they need to start an environmental study in 2018 concerning an emergency detour across the river. The mayor of Nipigon indicated that they have been asking for an emergency detour route for 10 years.

Just before I was about to publish, I found a Technical Review. So I deleted all of my ranting about having just three bullet items of information. Now I will try to summarize 110 pages of information.

The obvious problem is that 40 bolts broke! The investigation revealed that some of the bolts had already broken during the previous six weeks of service because they were rusty. The rest broke with a cascade failure. (When a bolt fails, the remaining bolts have to hold more force, causing some to break, which means the remaining bolts have to hold more force, causing....)

|

| Technical Report, Page ii |

But of course the real issue is why did the bolts break. We start with a diagram that explains the terms in the bullet items.

|

| gov.on.ca-investigation |

|

Technical Report, Page 75

|

|

| Technical Report, Page iii plus Paint |

|

| Technical Report, Page 5 |

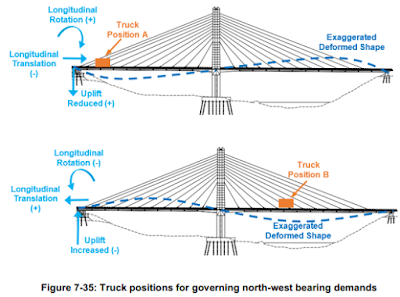

The contract drawings indicated that the bearings should accommodate rotations about the horizontal and vertical axes. And the contract drawings specified rotations that were less than required by some code. The bearings were not designed to accommodate rotations. So whenever a heavy truck rolled across the bridge (Figure 7-35 above), different parts of the PTFE surface would basically get smashed.

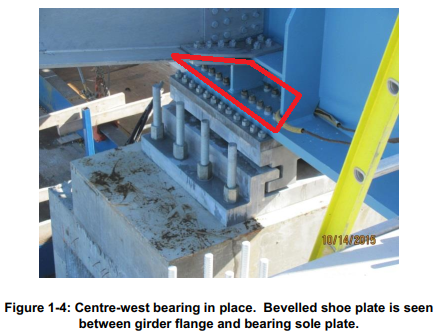

In summary, a bad design of the bearing did not accommodate rotational forces and a bad implementation of the bearing (no field modifications to keep the upper and lower plates parallel) damaged the bearing surfaces. The increased bearing friction of the PTFE surfaces caused the shoe plate bolts to be subjected to unintended shear forces. The rotational forces that were not absorbed by the bearing caused a "non-uniform bolt force distribution." [Technical Report, Section 9, sixth bullet] This is why several bolts broke during the weeks before the cascade failure.

|

| EngineersEdge |

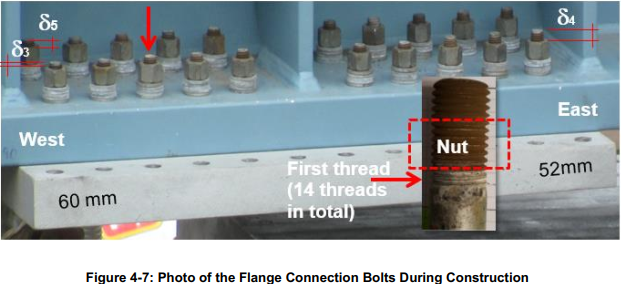

A huge (ridiculous that it could happen and ridiculous that it was not caught) problem is that some of the nuts were not tight enough. In fact, some of them were loose! And the amount of tightness varied significantly. So the tight bolts would be the first to fail. The picture below shows the inspector should have been suspicious because of the variable number of threads showing that was not commensurate with the thickness of the shoe plate. And the inspector could have easily determined the seriousness of the situation if he was carrying a torque wrench. In fact, given that some of the bolts were loose, using just a cheap end wrench would have flagged this very serious issue. [Section 4.4]

|

| [Technical Report, p10] |

Taking another look at the shoe plate after failure, note that the middle of the shoe plate was bent up so much that it cause a plastic deformation of the plate. (If the plate had stayed in its elastic range, it would not have left a gap in the middle.) To compound the problem of loose flange bolts, the strength of the steel specified for the shoe plate on the fabrication drawing was less than the strength on the contract drawing. [Technical Report, p31, first bullet]

|

| Technical Report, Page ii |

Cyclic loads cause metal fatigue. Inspection of the bolts after failure showed axial bending metal fatigue. "Overload permits issued by MTO indicate that just under ninety trucks over 60 tonnes (the weight of a code design truck) potentially crossed the bridge. The number of heavy trucks crossing the bridge is similar in magnitude to the number of crack propagation cycles seen in the striations of the fracture surface of some of the bolts." [Technical Report, p87]

This is the temporary repair that was completed February 26, 2016 that allowed both lanes to be opened and allowed trucks to use the bridge again.

|

| MTO, p1 |

|

| MTO, p2 |

Given the number of problems found during design and construction, you have to wonder about the competency of the various government agencies charged with inspecting the design and the construction. This article asks why wasn't the lack of effective oversight also investigated. Building code departments are supposed to do more than collect fees and bribes. (Another competency article)

|

| Ted Gregory shared Eastbound CP crosses the Nipigon River a few weeks ago. Behind it is the brand new (2015) Trans-Canada Highway bridge. But only 2 lanes are open, as the other half of the bridge is still under construction. I Believe the second structure has been delayed after the pictured highway structure was shutdown. On January 16, 2016, winter storm gales snapped an expansion joint that led to one half of the bridge being raised 24". Not 2.4, 24. Last I heard, no formal determination of cause has been made. |

Demolition of the old bridge.

(new window)

A different view of the bridge. And the railroad bridge next to it has some character. I'd have to add the labels bridgeTrestle, bridgeTruss and bridgeGirderSteel for that bridge.

(new window)

A different view of the bridge. And the railroad bridge next to it has some character. I'd have to add the labels bridgeTrestle, bridgeTruss and bridgeGirderSteel for that bridge.

|

| Steven J. Brown posted Canadian Pacific AC44CW 9758 (built 2003, starred in the 2010 movie Unstoppable as AWVR 767) westbound crossing the Nipigon River at Nipigon, Ontario - February 3, 2023. Bob Harbison: That bridge looks like something a model railroad made from a few different kits! Looks like they've replaced some spans over the years. |

I 1st saw new bridge several June 23, 2021,and was taken aback by its modern design. the video of taking apart old bridge was absolutely fascinating.

ReplyDelete