See the CWP&S Yard notes for satellite and topo map information.

"Over fifty percent of the component parts of the International Harvester Corporation had its origin in Plano." [KendallKin]

Products: Manure spreaders, Wagons

When I studied the Chicago, West Pullman & Southern Railroad, I learned that International Harvester had the industrial area between 120th and the railroad and between Loomis Street and Peoria Street. It is now a solar panel facility. This Plano Company explains why IHC had that land.

The right side of this aerial photo includes the West Pullman Station. The plant on the north side of 120th Street was Ingersoll.

When IHC was formed, all five plants made binders. IHC retooled some of the plants to make other implements that the farmers needed. Manure spreaders were becoming important because more and more farmers were hauling manure to their fields because decades of farming were depleting the nutrients in the soil. The rich prairie soil was no longer very rich.

Update:

|

| David Daruszka commented on a posting Plano Works |

|

| 1907 Annual Report, p 37 |

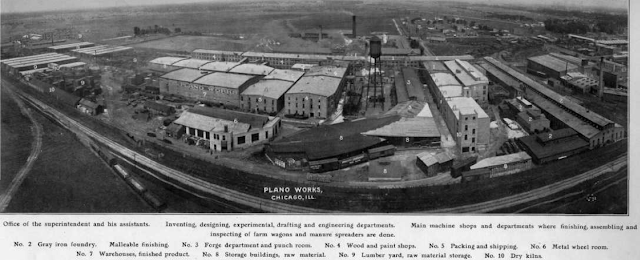

Area of real estate: 42 acres; Land occupied: 42 acres; Floor space: 607,058 sq. ft.; Employment: 1,350; Annual capacity: 57,500 machines [1907 Annual Report, p 37]

When I studied the Chicago, West Pullman & Southern Railroad, I learned that International Harvester had the industrial area between 120th and the railroad and between Loomis Street and Peoria Street. It is now a solar panel facility. This Plano Company explains why IHC had that land.

The right side of this aerial photo includes the West Pullman Station. The plant on the north side of 120th Street was Ingersoll.

|

| 1938 Aerial Photo from ILHAP |

When IHC was formed, all five plants made binders. IHC retooled some of the plants to make other implements that the farmers needed. Manure spreaders were becoming important because more and more farmers were hauling manure to their fields because decades of farming were depleting the nutrients in the soil. The rich prairie soil was no longer very rich.

One of the most important problems confronting the American farmer today is that of maintaining the fertility of the soil. Experiments have proved that ordinary barnyard manure is the best fertilizer. The old way was to haul the manure out to the field in wagons, and pitch it from the wagon into small piles over the field. The manure spreader serves as a wagon for hauling the manure, and when in the field, with a simple movement of the lever, the power is transferred through the rear axle and the

machinery set in motion. It spreads a load five times faster than it can be done by hand, the manure being torn into fine shreds and distributed evenly over the field. [1907 Annual Report, p 37]

In December, 1906, the Company purchased at Newark Valley, N. Y., and leased at Waterloo, Iowa, the manufacturing plants of the J. S. Kemp Manufacturing Company. The Company thereby obtained control of the Kemp Spreader patents, and entered the field of manure spreader manufacture with results which have shown the wisdom of the undertaking. [1907 Annual Report, pp 14,15]The manufacturing of harvesting machines was transferred to Deering Works in 1905 so that the Plano Works could be retooled by 1907 to build manure spreaders and wagons. IHC advertised more than one brand (e.g. Corn King and Cloverleaf) until it used McCormick-Deering in the 1920s and 30s.

Update:

|

| Bill Molony posted [The comments confirmed that the building we glimpse on the left was an International Harvester plant.] Sonny Kortvely A few years ago I traveled into the area an noticed that even the CWP tracks crossing 120th street had been torn out an Ingersol had been torn down also. Vince Shelton The CWP tracks had been pulled up for decades as well as the plant. Last time I remember the plant standing was around 1999, and that's maybe. Sonny Kortvely When I started working at the plant in January of "66", it was called West Pullman Works, then I think sometime in the late "70s" or early "80s" it was named West Pullman Plant. Now all the buildings on the grounds have been torn down an solar panels (hundreds of them) have been installed on grounds. I left Harvester in January of "80" while the union was on strike against the company, an the company finally closed the plant a year later. Note: In the top picture of the train rounding the bend, the factory in the frame was Mallable Casting Company which was just west of I H and across the CWP tracks. |

Was this one of the companies mentioned in the top paragraph that started in Plano, IL, or was this yet another company in Plano?

John Twait posted two photos with the comment: "Did anyone ever use farm equipment made by independent harvester out of Plano Illinois."

Kenton Seydell: How did the elevator go up from the transport mode?

John Twait: Kenton Seydell there was cable with pulleys that u hand cranked up

|

| 1 |

|

| 2 |

I had a salvage yard in the late '90s across from this old facility at 120th and Peoria, next to the old fire department....Ingersoll Rand was still there....the solar array was built after I had left the area....I pulled up the rails in the yard there that I was renting! It was a maintenance shop grounds for the West Pullman railroad before I used it....

ReplyDelete