(Update: the information concerning measuring track geometry and grinding the rails has been moved to its own set of notes.)

|

| Screenshot from video Jeff Frost posted Steam locomotive wheels being turned on a 90" wheel lathe built in 1912 for Leigh Coal and Navigation. The lathe now uses Mimik tracers (1960's technology) that was installed around 2009/2010. The wheel set is around 50" in diameter and is spinning around 13 rpm. To change speeds you have to change out the gears. There are two sets of gears that can be physically installed; each set of gears can be installed to give two variations of speed; large gear on top and small gear on the bottom or small gear on top and large gear on the bottom. This gear change is near the motor. The next set of gears is engaged with a lever. This gives a slower and faster speed for the gear combination near the motor. The next set of gears chooses the drive to the the large ring gear on the face plate (90" in diameter of the face plate. You can see the teeth on the tailstock faceplate in this picture) or the smaller ring gear (about 50-60" in diameter, only on the head stock). With all these gears there are 8 speeds for using the large ring gear and 8 speeds for using the smaller ring gear. The large ring gear was used for the very slow speeds when using the tool steel tools (roughing tool, flange form tool, outside radius form tool and full tread (5.5"+ wide) form tool. The small ring gear is what we use now for the higher speeds with using carbide insert tools; this would have been used before with small drivers (like 36" or less in diameter). The top speed for the small ring gear is around 18 rpm. For turning the journals on the axles we use an auxiliary motor (by passes all of the straight cut gears) to spin the wheel set around 30-32 rpm |

|

| Jeff Frost commented on his posting This was taken last Monday.The 90" diameter faceplate dwarfs the 49" wheels. Jeff Frost posted Turning 50" diameter steam locomotive wheels on a 90" wheel lathe built in 1912. I have turned wheels as small as 30" and as large as 80" on this machine. The tooling was changed from the HSS roughing & form tools to tracers and carbide insert tooling about 14 years ago. Kelly Anderson took this picture |

|

| Thomas E Lucas commented on Jeff's post This 60-inch wheel lathe was built in the late 1800s and is still in use today on diesel traction wheels toady. It's found in the C&G RR shops in Columbus MS along with other machinery of the same era. The shop is attached to the 1887 roundhouse. Dennis DeBruler: Thomas E Lucas Thanks for mentioning the roundhouse. I was not aware of that one. https://maps.app.goo.gl/HscSYz16h2qrigeV7 |

This video shows that the reason the wheel surface has a taper is to handle curves in the track. Unlike a car, which has a differential, the rail wheels turn at the same rate. So they change the radius that is making contact with the rail to change the distance covered during each turn of the wheel.

|

| Robert Learmont posted There’s just something about the look of the tread of a freshly trued wheel. |

|

| 14:52 video @ 5:49 |

|

| One of four photos posted by Jim Kreider (source) Trevor Heath This group and its library of documents may be of interest: https://www.facebook.com/groups/444442242651852/ |

|

| Rich Behrends posted THE DOUBLE-ENDED LATHE for turning wheels is an essential part of a locomotive workshop’s equipment. The wheels and crankshaft shown in this picture belong to a two-cylinder 2-6-0 locomotive under construction at the Belfast works of the LMS, for service in Northern Ireland. The wheels revolve with the slotted face-plates, and the turning tools are held in the massive slide rests on either side of the workman. [Many English locomotives had the connecting rods inside the wheels. American locomotives always had the rods outside the wheels. Look at all of the shavings on the floor under the wheels.] |

|

| John Abbot posted Denver Tramway Co machine shop...1910... [You can see the building was built back when they used shafts and belts to power the machines because some of the belt pulleys are still hanging from the columns.] |

|

| John Abbot commented on the above posting [Note this unit was still driven by a shaft and belt.] |

|

| John Abbott posted |

|

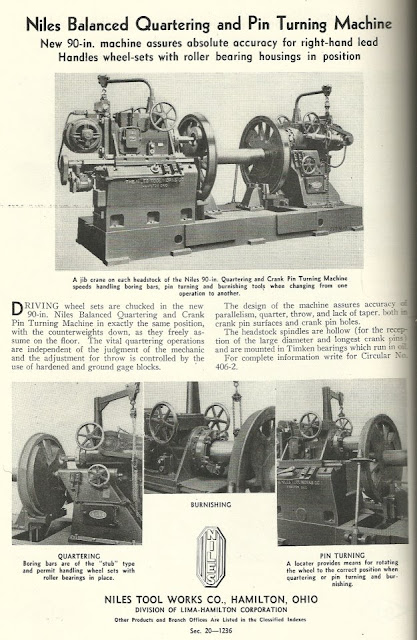

| John Abbott posted wheel-lathe-work Andy Pullen Actually, that's a quartering machine. It's used to machine the crankpins exactly 90 degrees apart to make a locomotive have no "dead spots" so it will always start. That machine actually looks like the shop in Irondale Alabama. The diesels on the right, top side of the photo give it away. I worked in that shop for 18 months.Bob Gaston Norris Steam Restoration Shop, Norris Yards, east of Ruffner Road, Irondale, Jefferson County, ALAndy Pullen That's it. The program was shut down in 1994. The auction was the first week of March of 1995. The locomotives went back to the museum. Roanoke for the 611 and 1218. 2716 went back to KRM. [Even though it is not a wheel lathe, I include this picture because it shows the amount of big (expensive) machine tools that were needed to maintain steam locomotives.] |

|

| John Abbott posted Andy Pullen That is a railroad wheel lathe. It's for turning the tires on both wheels at the same time. There was one in the Steam Locomotive shop in Irondale Alabama. Except, that machine was built by Niles. John Abbott Niles - Bement - Pond Company ...they must have split up and went their own way ... as do most inventers with different ideas... Robt Bernstein No, they didn't split up, they joined together. Niles in Ohio, Bement in Philadelphia, and Pond in New Jersey. Pratt and Whitney bought NBP later, I think. [Note it is old enough to be driven by belt from a line shaft.] |

|

| John Abbott posted 1913-wheel-lathe-work Andy Pullen Strasburg RR.George Atchison Looks like a narrow gauge axle.Casey Sowell I'm nearly positive this is standard gauge, likely for our locomotive #475 back when she was in for wheel work years ago. The base for the wheel lathe is set down in to the floor so it doesn't look nearly as large in this picture.Casey Sowell Worked next to this machine all day today (the last 4 weeks straight actually). Turns up to 90" drivers. Sometimes it will run for weeks on end when there is wheel work to be done and other times it sits idle for weeks. Makes a HELL of a racket when in operation. |

|

| John Abbott posted 1913-wheel-lathe-work Andy Pullen I believe this is also Strasburg. |

|

| Skipper L Swartout posted via Dennis DeBruler New York Central Shop at West Albany, NY 12/17/1946 John Scott: Center drive axle lathe. |

|

| Brielle Brown posted [Rock Island] Silvis wheel shop [I see at least three wheel lathes.] |

|

| R.B. Holmes, Aug 2019 in Age of Steam Roundhouse |

This Nashville Steam post put me in the middle of six photos.

|

| 2 A view from behind the tool post of the wheel lathe. |

|

| 4 Shane uses a Pi Tape to measure each wheel center circumfrence to determine the proper bore diameter of the new tires for the correct interference fit. The pi tape is accurate to .001" |

|

| 5 Once the measurements are taken, Alex writes them down on the inside of the wheel center. |

|

| 6 Alex and Shane taking a measurement of a wheel center with the pi tape. |

|

| John Abbott posted |

|

| John Abbott posted [A steam locomotive tire was a steel band that was heat shrunk around the hub and spokes. It could be replaced after it would be too thin because of multiple wheel lathe turnings.] |

|

| John Abbott posted locomotive-wheel-lathe-machine-niles [They must also be rebuilding something else.] |

|

| Dave Cavanaugh posted David Williamson Strasburg Railroad...currently adding 12,000 square feet of NEW shop space for steam locomotive repairs! Dave Cavanaugh http://www.rrmuseumpa.org/index.shtml |

|

| Robert Phillips commented on the above posting Found this in New Orleans... Belongs to LASTA(Louisiana Steam Train Association)... Mounted to a flatcar:):):) |

|

| Robert Phillips commented on the above posting They loaded the "wheel lathe" and , ha, anything they wanted to lift with this rail crane:):):) |

|

| John Abbott posted Craven Bros railway wheel lathe c1909. |

|

| David Daruszka posted Checking the gauge on a driving wheel at the Pennsylvania Railroad. Given the gearing on the wheel, it belongs to an electric locomotive as opposed to a steam engine. Ross Haygarth I always wear a straw boater when measuring the track of my new Choo-Choo David Daruszka Easiest way to identify a supervisor. Jerome Clements They were, and still are, known as a "skimmer" on this side of the pond. They are still available here, as I'm sure they are in the UK. Robert Livingston Quill drive, I am guessing 62" diameter, a standard for PRR ("The Standard RR of The World"). Mark Gulbrandsen All of the equipment in this shop is still in use. https://www.youtube.com/watch?v=SYd9Pd58ksA |

|

| Screenshot (source link in case the video link is not permanent) [The diameter of the tire is smaller than the wheel so they have to heat it to expand it to get it off.] |

|

| Center for Railroad Photography & Art posted Goodness gracious, great balls of fire! It's #WorkerWednesday! In this image from the John Gruber Collection, Duluth and Northeastern Railroad workers utilize a "ring of fire" when changing a driving tire on DNE 2-8-0 steam locomotive no. 27. Gruber shot this image in Cloquet, Minnesota, on July 15, 1963. Gruber-05-30-017. Joe Menard: I like the guy smoking a cig while leaning over a welding tank full of explosive gas. LOL! Plus the building is totally post and beam construction in wood. ha ha. [Some comments about you normally remove the driver before you change the tire. And you have to at least have the side rod off to change the tire.] Howard Pincus: They were probably shimming a loose tire. At that point in the game, it was "patch it up for a few more months, diesels are coming." [1963 was very late for switching to diesel.] I was involved in doing this job on a 2-8-0 in Quebec in 1973. Some tires were loose (dragging brakes) and we used a heater ring on the drivers, right under the engine. Expanded the tires and slipped 1/16” shims between the tire and wheel center. Raised the axle off the rail with air jacks in the pit under the engine. A hot job. |

|

| Michael Hall posted In the Golden Age of Railroads, the old steam locomotives required a tremendous amount of maintenance. One pesky problem was that every time you did an emergency braking, and allowed the wheels to skid on the rails, you left flat spots in the wheel surface. The wheel surface is actually a steel tire that had to be heated to expand it, then pushed onto the wheel, and then let cool to shrink it tight to the wheel. Here is how that is done. The flames are from a pipe ring with nozzles, the fuel is natural gas. Aidan Clayton: Doubt they were changing the tyre as the wheelset would have to be removed from the bogie and the process of removing and refitting the tyre required imense heat and force to both remove and refit it also the tyre was held in place with a Gibson ring (think circlip) which was fitted to the rear of the wheel. Don Adamson: I never knew this could be done without taking the wheel off the locomotive first. Michael Hall: Don Adamson Yes, but you have to remove the crank arms, brake blocks and brake linkage (if so equipted) and the sand drops. Then most tires can come straight off. They make special tooling to do this. I've changed them both ways. Robert Eisenman: Aidan Clayton nope, heating the tire off is exactly what is happening here, doesn’t take that long and once hot it can be walked off with a couple bars. Christo Sanchez: Yep- great trick. My dad taught me that ages ago. He was a machinist, so taught me all about that, and I just used it to put universal joints in my driveline. Left the u joints in the freezer and heated up the driveline a bit with MAPP gas, and got them in a hurry with no issues. Lovely! Geoffrey Us Whellams: Wheels are complex. The Wheels and axle are one solid, flanges prevent the wheel from riding off the track but the flat is tapered from the outside face of the flange to the outside face of the wheel . This enables the “Differential” Requirement as the train rounds a curve, the outer wheel has to cover more distance than the inner Wheel, the taper allows for this . The weight of the train pushes to the outside of the curve so the point of contact is With larger diameter of the wheel With the inside rail is on the small side. Aidan Burke shared Corey Phillip Jones: You can use a wheel lathe to cut the flat out without having to replace the tyre. Brian Oh: The wheel steel is actually harder than the rail so it would also cause a a big flat spot on the rail. The #1 cost incurred by the railroads was real estate, #2 was rail. Jan-Erland Asbjørnhus: Brian Oh Because the rail is already flat, a sliding wheel will not cause significant damage to the rail, but the wheel gets a small flat spot. If the locomotive gets wheel spin, however, they will leave a mark on the rail surface. Modern rails have a hardened rail head, so the problem is not that big nowadays Brian Oh: Jan-Erland Asbjørnhus - not all modern rail is head hardened, that is generally reserved for areas that are subject to a lot of stress. I remember seeing a lot of wheel burns on older rails from the days of steam. A lot less common with modern diesel locomotives. Jan-Erland Asbjørnhus: Brian Oh Here in Norway all rail purchased the last 15 years is head hardened. We have a few marks on the rails at the museum railway where I am Master of Way, but considering we have 26km of track with rails put in between 1890 and 1908, it’s not enough to be a big problem. It does help that the old locos have a lower axle load. The worst offenders on the national network here are, powerful electric locomotives on pre 70s «soft steel» rails. James J Bugielski: The wheels would also develop flat spots if the locomotive was stationary for extended periods. William Peters: A lot of small towns would use the cast off “tires” to alert the community if there was a fire by hanging it in the center of town with a hammer. Bob Good: One of the best train books that I got at the Strasburg Railroad is titled, Basic Steam Locomotive Maintenance. The other books were all picture books showing the old number xxxxx engine rounding the famous blah blah curve of some such thing and really told me nothing about how stream engines work. When I picked this book off the shelf and opened to a random page and read, “first, lay the engine on its side”, I knew this book was for me. |

|

| Mike Ray posted Preparing to install a driving tire on one of N.C.St.L 576`s drivers at Chattanooga Tn March 2022 |

llll

%20Facebook.png) |

| Facebook Reel |

|

| Tim Starr posted A locomotive shop employee is adding tires to a wheel set at the Illinois Central's Puducah KY shops in 1956. The last steam engine was outshopped in 1958. Paducah was opened in 1927 at a cost of $11.4 million. (Robert Hale photo) |

Steve OConnor posted two pictures with the comment: "1947 Locomotive Cyclopedia."

Jeff Turnfer posted four pictures with the comment: ''March 1957"

Another big machine needed to maintain steam locomotives:

|

| 1 |

|

| 2 |

|

| John Abbott posted Fabrica brasil 1880 Ray Cook That's a gaggle of wheel lathes. |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Steve OConnor posted |

|

| Steve OConnor commented on his posting |

|

| Darrell Burkhalter posted My Grandfather "Happy" turning drive wheels around 1912 in Momence? Picture says Kankakee. |

|

| Maine Locomotive & Machine Works posted, cropped The wheels on the Lathe go round and round! |

|

| Milan Mucha commented on the above post My job |

|

| Bill Boyd commented on the above post This is how rail wagon and rail car wheels are turned from start to finish less than 10 minutes and totally accurate-- |

|

| Age of Steam Roundhouse Museum posted The AOSRM back shop was in full production the past few weeks with driver wheel work. Shown here are locomotive #19’s drivers set up it the wheel lathe (top) and quartering machine (bottom). The shop rumbled for days when these steam era machines were doing what they had been designed for. Great to see this historic equipment operating in these modern times. |

Modern diesel locomotives and rail cars also get their wheel sets trued up in a wheel lathe. The lathe is just not as impressive (big) as the old steam locomotive wheel lathes. My uncle, Douglas Weitzman, would talk about a locomotive needing its "toes trimmed." Another reason for wheel lathes is to remove flat spots on car wheels. Flat spots are created when a train goes into an emergency stop and the brakes are applied so hard that the wheels do not turn at all. They just scrape (squeal) along the rail. When you are standing at a crossing you can tell if a car with flat spots is going by because there is a loud, rapid thump-thump-thump as it goes by. However, it appears that they have figured out how to stop a train quickly without locking the wheels. The train did stop quickly enough that some of the automobiles in the autoracks got wrecked.)

A Metra video and article of how they "re-profile" their coach and engine wheels in place. They now using a milling head rather than a lathe tool.

Jim Morris How many times can a wheel be trued before replacement in necessary?

Metra Typically, a wheel can be re-profiled six to seven times before replacement is necessary.

Amtrak's wheel truing building near the south side of their Chicago Yard. Fortunately, Mark Hinsdale caught the sign back when you could still read it. It says: "1700 So. Lumber Street Wheel Truing Building". In his following photo you can see that they extra wheel sets stored on the right side whereas I caught them on the left side.

It looks like they have portable units for diesels.

Sharon Yin posted two photos with the comment: "rail head wear measurement instrument."

William Ridgeway That does not measure vertical wear though.

Sometimes, the wheel set is just scrap metal.

I knew that cold weather caused rail pulls. Bad wheels cause rail defects that are a source of the rail pulls. Some selected comments from a post. They were rather hard to find because I had to dig through a lot of snarky comments.

Daniel Grande Once had 32 broken rails behind train with a rough wheel.

Joseph Robert Whelan That’s a bad day.

Daniel Grande Joseph Robert Whelan ya started around midnight and 2 crews about 24hrs to repair all, over 36 miles of track, was around 1980.

James Michael Forman Flat spots on wheels are also a big factor. They have wheel impact detectors in some places. If you have severe flat spots, you usually have to set those cars out.

Joe Westbrook flat wheels cause a lot of broken rail.not always a [rail] defect.

Brian Westhouse Wheels with surface defects on the tread cause rails to break, not necessarily slid flat wheels. That's why they have Wheel Impact Load Detectors along the track.

Jamie Scott every day in cold weather every time a flat wheel hits a week spot or fatigued rail

Don Fountain They are more likely to pull up part at a joint than to snap into, but it does happen even with good rail on the main line, but very seldom. The most I have heard of in one night is two per hundred miles.

Dennis DeBruler Thanks for some real information. For a group with "(railfans welcome)" in the title, many of the comments were useless, if not offensive, and made it hard to find the informative comments. I did find the handful of comments that taught me that the problem with wheel defects is not just the noise they make as they roll buy.

Todd Young Don Fountain , who u work for bro ? Generally true but we got 1947 132 with 1/2” head left no surface sketchy ties on parts of the territory.

Don Fountain My experience was for excellent rail between 2000 and 2012 when I retired on the line that had a lot of curves and not a lot of heavy coal cars. This was under the management of one excellent president CEO Michael Ward on CSX.

He ran or railroad for the long-term not for just for short-term profit.

Adam Schrodt Well on my ten hour shift today in -25 with -50 windchill my train was stopped for 3 pull aparts and 2 broken rails on an 80 mile run.

Video of a GP10 having its "toes trimmed." (source)

Video of IRM's Putnam working since 50 years after it last ran.

Ann Arbor's steam locomotive wheel lathe

A Metra video and article of how they "re-profile" their coach and engine wheels in place. They now using a milling head rather than a lathe tool.

Jim Morris How many times can a wheel be trued before replacement in necessary?

Metra Typically, a wheel can be re-profiled six to seven times before replacement is necessary.

Amtrak's wheel truing building near the south side of their Chicago Yard. Fortunately, Mark Hinsdale caught the sign back when you could still read it. It says: "1700 So. Lumber Street Wheel Truing Building". In his following photo you can see that they extra wheel sets stored on the right side whereas I caught them on the left side.

|

| 20150513 1487c |

|

| Scott Gist posted, cropped Getting a little wheel machining done. Scott shared a post of a video showing a lathe in operation Mark Rickert seems harder than it should be. A brake shoe with a cutting head is all that's needed, and hoe they profile the 1630 due to excessive strait rack. |

|

| Jerry A Lee posted CN shop Memphis TN [This shows that wheel set replacement and refurbishment are a significant aspect of locomotive maintenance.] |

|

| United States Steel Corporation posted The wheels on the bus....came from #USSteel Donald Bowman: That was the old Merchant Mill. James Torgeson shared Greg Beyerl: Ray Schloss looks like they still need turned on the Vertical Lathes to the final specs. I've turned a few wheels myself in Mckees Rocks PA. Trinity Industries. Greg Beyerl: I helped forge quite a few train wheels. Axles and gear blanks myself, at Standard Forged Products in Mckees Rocks,PA. They use a 10,000 ton press from Bethlehem Steel in Bethlehem, PA. The press is over 70 years old. James Torgeson Author Admin +2 |

|

| BNSF's wheel shop has produced over 3,000,000 wheelsets. [Satellite? Google Maps doesn't label the yard. Normally they are pretty good about putting BNSF on there yards.] |

|

| Robert Learmont posted We cut our 15,000th wheel on our wheel truing machine in Galesburg, IL tonight. Galesburg, IL Diesel Shop 6-18-2021. |

|

| Comments on Robert's post |

|

| Robert Learmont posted BNSF 3781 gets its wheels trued. Galesburg, IL 2-12-2022. Chris Onnink: A C4 getting wheels trued, what a shock! [I recognize a C4 as a 3-axle truck whose center axle does not have a traction motor. I now wonder if they wear worse than a standard 3-axle truck.] Nate Weeks: How do I get this job Robert Learmont: Apply online just like any other job these days, get through the hiring process, get through or test out of a machinist apprenticeship, let time work you through the seniority roster, ask to be trained and get qualified on the machine, come in on your own time to train and qualify, and then bid on the wheel truing position someday when it gets posted. |

%20BNSF%20Historical%20Society%20_%20BNSF%203781%20gets%20its%20wheels%20trued%20_%20Facebook.png) |

| Comments on Robert's post |

|

| Alex Almada Suarez posted Found this in my stuff Vernon Davidson Many uses, ury even has a little pointy thing at the bottom, that's a gauge too. Carl Thompson we called a hook guage I used it in conjunction with the M gauge. Jim Pearce U use it when changing wheel sets to determine how much metal is in the wheels. Used one for many years. Corey Simmons Flange height thickness and width. And rim thickness. Jesse James Thomas Corey Simmons and tread. Corey Simmons Jesse James Thomas not being an ass but how does it measure tread. Jim Quirk Corey Simmons the numbers down the side tell you the tread thickness. You put the gage on the inside of the wheel with the tip of the the finger on the tread, they are measured by 16th’s of an inch. This gage was normally used by the RIP inspector, there is a simplified gage normally used by yard inspection. Jack Immel Pratt and Whitney gauges. Ron Huizenga Thin flange or high flange did many a wheels. John Cox I have one. I almost lost my fingers one night when the hostlers ran into the engine consist I was under while gauging wheels. Mike Heidt John Cox no blue flag or other protection? John Cox Mike Heidt yup. There was blue flag protection but no derail. |

Sharon Yin posted two photos with the comment: "rail head wear measurement instrument."

William Ridgeway That does not measure vertical wear though.

|

| 1 |

|

| 2 |

|

| William Ridgeway commented on Sharon's post |

|

| Mike Merriman commented on Alex's post |

|

| Marty Bernard posted OK, What Is It ? In a CSX Shop, Duane Hall photo, October 1992. Marty Bernard shared [Dario Carreiro added several comments with photos of their lathe being replaced.] |

|

| Between the share and the post, I had to dig through a bunch of stupid comments to find some useful information. Judging from the more useful comments, this can be caused by a locked pinion gear, a "birdnested" traction motor, or someone forgot to release the handbrakes. Robert J. Riley We always called em birdnested here when the string band breaks and slings the windings. Joseph Freeman Looks like it derailed and kept going. Opposite wheel wear on inside of flange. Samuel Foster Still glowing red that's impressive. Scott Wilcox Got one almost this bad as second unit on a grip on-grip off train about two years ago. Inbound got it that way...never checked their power. Hand brake applied on second unit. I quite often catch hell for delaying trains, but not that day. After finding the brake on, I had a bad feeling and checked the wheels. Good thing. 8 inch flat spots were pretty obvious by looking. Chief still wanted me to take it that way because "It was ok coming in, it's ok to go." We're told by the company and the unions that "we can not refuse" what we are told to do. Funny how that goes away when you stand your ground in a situation like this. Robert J. Riley I got told to take one with 4.5 flat spots. I was told there would be an investigation if I refused. I ran that shakin somebitch at 60MPH with a freaking out conductor. He said this fucker is gonna hit the ground. I looked at him with a straight face and said I HOPE SO! That will be the winning ticket to the railroad lottery. He looked at me in horror and we rode another 125 miles with it like that. They bad ordered it in Fulton KY and chewed his (the official who told us to take it) ass out... 6 new wheel sets.....yeahhhhhhhhhhh.... Scott Wilcox Robert J. Riley Probably some new rail along the way too! Robert J. Riley No idea Scott but there were some very pissed off people about it. To top it off those engines belonged to the NS and were only being pirated to make a turn to Fulton KY and back to Memphis before we sending them back to NS on 397 to go to Sheffield AL. Kinda hard to explain that one too. CN at the time was notorious for stealing foreign power in the yard in Memphis, using it and bringing it back with way less fuel and giving it back without even replacing the fuel they used. The BNSF now takes their power off in Memphis on coal trains going to the coast because CN would add 60 or 70 cars of slop on the headend on them and burn BN fuel for "free". UP shut a pair of locomotives down on the fly up in TN because their crew showed up in Johnston Yard to find no locomotives. Omaha tracked them with the Qualcomm and saw they were running, shut em down. I'd like to think upper management didn't know this was going on, however I can't see how it was this rampant and no one knew.... Rebecca Glanz Question is how far did this thing go? (Job security for track guys btw) I have seen one that was drug for 100 miles and it didn't look nearly this bad. Jason Lambert From Toledo to Indianapolis. Robert J. Riley Jason there’s no way that lasted 227 miles sliding. Looks more like what I’ve seen after 5 or so miles at track speed. Once it gets hot it goes pretty quickly. This must have been a Geep or older SD or been DIT as the speed sensors on anything else would have detected a locked axle and set a trainline alarm. |

|

| Screenshot [Another post where I did not read all of the comments. But I did catch: "Mark Hillemann NOTICE ,,AIR HOSE NOT COUPLED." So I found this frame that shows the uncoupling.] |

|

| Maik Everding shared Mike Snow The failure is a result of an Inclusion ! [From what I gather from this and other comments is that the wheel broke. And every revolution made would create another damaged spot on the rail. The disk brake indicates that the wheelset was either on a locomotive or a passenger car, so someone should have heard this problem.] |

|

| Sam Carlson posted Broken wheel. This can't be good! Sam Carlson  I don't think it's the one that caused the Hawthorn Woods derailment. If it was, then for some odd reason, it was moved to Spaulding. I don't think it's the one that caused the Hawthorn Woods derailment. If it was, then for some odd reason, it was moved to Spaulding.[I hope the train was moving slowly. That had to cause a derailment.] |

|

| Ken Jamin posted The train ran seven miles with this much of the wheel missing! It was discovered on a roll-by iinspection. (Milwaukee Road 1970s) [There are several comments talking about sending cars that had been in Mexico to the RIP track "because somebody down there always stole all the chains and binders."] Keiwoon Krause I remeber hearing Hilary got a letter from the Milwaukee road president for spotting and stopping a train with a cracked wheel.Ken Jamin  Acknowledgement from the carrier was very spotty in later years. I once got a letter of commendation for spotting a sticking brake (sliding wheel) on an Amtrak train. But I got no acknowledgement for stopping a passenger train Acknowledgement from the carrier was very spotty in later years. I once got a letter of commendation for spotting a sticking brake (sliding wheel) on an Amtrak train. But I got no acknowledgement for stopping a passenger train when it was burning off a journal as it went by me. (See my article “Trouble on a Turboliner” in Trains magazine.) However, not long after, I was called on my day off to come in (they admitted they forgot to tell me the day before) and I agreed to do so. I got to work as fast as possible, @ 1 1/2 hrs late, but claimed eight hours per agreement. I got a letter of reprimand for coming in late and claiming more time than I actually worked. It took me a long time to get that letter removed from my file and left a bad taste. |

|

| Juan Perez posted Andrew Beauman shared [I scanned just the last 50 of 431 comment.] Morris Loeffler It was actually frowned upon to find wheel defects as a car inspector in a couple of locations I worked in the early 90’s. I only worked there for a check for a short time while furloughed from Engineering. I’ve seen far too many pile ups from these over my 40+ years. Brendan Murphy Morris Loeffler yeh it is too much lost time to cut that car out, (production over safety) but most managers don’t realise the damage and Mainenance it causes to the track , and then even more lost time when it fails in the section . Bear Drury Since the original poster is in Argentina, and since flat plate wheels haven't been allowed in the U.S.A. for decades, I suspect that didn't happen in the U.S.A. Michael Schmidt That's a straight plate wheel. Must be a reason why we got rid of them many moons ago. Henry Goodbread posted [There are so many garbage comments like "Flat spot !!!" that the one that caught my eye is now berried by the 545 comments. I think it implied that any rail this wheel rolled over will have to be replaced.] |

I knew that cold weather caused rail pulls. Bad wheels cause rail defects that are a source of the rail pulls. Some selected comments from a post. They were rather hard to find because I had to dig through a lot of snarky comments.

Daniel Grande Once had 32 broken rails behind train with a rough wheel.

Joseph Robert Whelan That’s a bad day.

Daniel Grande Joseph Robert Whelan ya started around midnight and 2 crews about 24hrs to repair all, over 36 miles of track, was around 1980.

James Michael Forman Flat spots on wheels are also a big factor. They have wheel impact detectors in some places. If you have severe flat spots, you usually have to set those cars out.

Joe Westbrook flat wheels cause a lot of broken rail.not always a [rail] defect.

Brian Westhouse Wheels with surface defects on the tread cause rails to break, not necessarily slid flat wheels. That's why they have Wheel Impact Load Detectors along the track.

Jamie Scott every day in cold weather every time a flat wheel hits a week spot or fatigued rail

Don Fountain They are more likely to pull up part at a joint than to snap into, but it does happen even with good rail on the main line, but very seldom. The most I have heard of in one night is two per hundred miles.

Dennis DeBruler Thanks for some real information. For a group with "(railfans welcome)" in the title, many of the comments were useless, if not offensive, and made it hard to find the informative comments. I did find the handful of comments that taught me that the problem with wheel defects is not just the noise they make as they roll buy.

Todd Young Don Fountain , who u work for bro ? Generally true but we got 1947 132 with 1/2” head left no surface sketchy ties on parts of the territory.

Don Fountain My experience was for excellent rail between 2000 and 2012 when I retired on the line that had a lot of curves and not a lot of heavy coal cars. This was under the management of one excellent president CEO Michael Ward on CSX.

He ran or railroad for the long-term not for just for short-term profit.

Adam Schrodt Well on my ten hour shift today in -25 with -50 windchill my train was stopped for 3 pull aparts and 2 broken rails on an 80 mile run.

|

| David Smythe posted Found this after tripping my DED. [He was a maintainer and this is one of the DED's he was responsible for.] David Smythe: Dragging Equipment Detector. Spring loaded paddle sticking up on both sides and between the rails. [Several comments about never seeing this failure mode before. And others speculating that the wheel was made in China. And others about laying off carmen and reducing inspections.] |

Video of a GP10 having its "toes trimmed." (source)

Video of IRM's Putnam working since 50 years after it last ran.

Ann Arbor's steam locomotive wheel lathe

Pete Kerlin: How much force is required to press the wheels on the axles. Do the wheels need preheated?

Ryan Flies: Pete Kerlin 140ish tons and it’s not preheated. But the axle and wheel have to be within 15 degrees when pressed on.

(So the gauge in the video is reading in tons of pressure.)

Jay Sanchez: Pete Kerlin where I used to work, the wheels were preheated to 80C.

Pete Kerlin: Jay Sanchez I wondered if wheels were heated to make it easier to press on the axles. I guess it varies for different shops.

Ryan Flies: I’ve worked many times on that very machine. That video and bearing mount were made in the shop I work in.

Chip Beyer: We at Jackson heated the wheels for our 6700s in an oven and they slid right on and let them cool. They set in minutes. One journal was insulated but it didn't matter.

A 3:09 video of wheel making and a 5:08 video in the comments.

No comments:

Post a Comment