|

| Paul Sequeira, Public Domain |

|

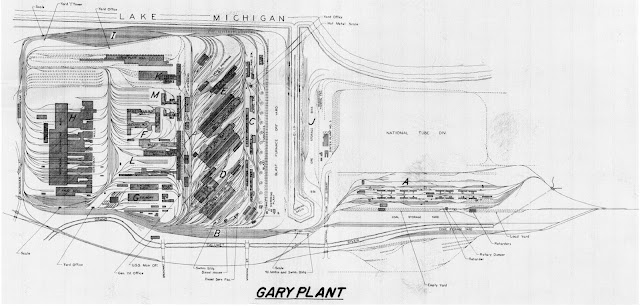

| Tom Cera posted U. S. Steel Gary Works USA view looking northeast from the south end of the plant. Circa 1930s (est). Bert Van Natter: I probably park my Mustang in that lot back in the late 60’s. |

|

| Jon Wolfe posted Gary works 1959 Donna Peck posted U.S. Steel Gary Works - 1959 Díaz Nebur: The Hay Day of the steel industry It was like a miniature city over close to 30,000 people working 24/7 Now it's less than 3,000 if that. Scott Gracie: The USW went on long strike in 1959.....this picture must have been taken in the early part of the year before the USS Gary Mill went idle after the rank and file walked. Rich Paskash: This photo sure pops up a lot. It shows the No. 1 BOP Shop and O H. No. 1 next to it. I worked in Steel Production at USS-GW for 7 yrs. mainly No. 5 O.H. and the BOP Shop. Tim Lavin: Damn look at that sky by the coke plant! There are no mountains there, just mountains of smoke, dark as death. David Marsh: That parking lot is almost empty each day now. |

|

| Kirk Martinsen posted City of Gary Indiana 50-year Jubilee with USS above. 12 blast furnaces and all open hearths, the sintering plant, and 46 slab mill look brand new. All men in the city were required to grow facial hair. Josh Rothchild: You just made that up about the beards, right? Bill John William Allred: Josh Rothchild true, absolutely!! They even had a mobile paddy wagon on Broadway and would throw your butt in if you were caught without a beard downtown, folks on the sidewalk had a good laugh at the caged guys! All in fun of course!! No penalties!! Fun times, I was there, remember it well .. I have a set “2” golden jubilee ash trays, @ 2” x 6” black with golden inscription Golden Jubilee, Gary, Indiana, Seeing it in its current condition is almost like visiting a family members burial site.. sad-sad🙏🙏 Gregg Leech: I see the primary rolling mills with their soaking pits, if I remember the order correctly going towards the lake from the shops... Rail Mill, Billet Mill, 36" Slab, 44" Bloomer, and the new 46" Slab mill. 210 Plate Mill hasn't been built yet. Karen Snepp: It was just part of the celebration, because facial hair was common in 1906, the year they were commemorating. Rieta Andrelia posted with the same comment Michael Siola shared |

|

| 1 |

|

| 2 |

|

| Nathan Stephens posted An aerial view of U.S Steel Gary Works in Gary, Indiana. Chris Pool: 3 plant and the dox!!! |

|

| Ashanti Gillette posted U. S. Steel Gary Works, Gary, IN Jessica Van Giana shared |

|

| Millard Fillmore posted USS Gary works as seen from the top of the shuttered Coke Mike VanVleet: Gary Works covers 7+ miles of lakefront |

Photos of Gary Works taken by plane this past Saturday. Was neat to see the Lake Michigan side of the mill, as my drone can’t go that far. Got lucky with Gary Railway moving some coke around as we flew by!5/1/25

|

| 1 |

|

| 2 |

|

| 3 |

|

| Tom Wells posted Looking North/Northeast from the Gary State Bank building toward Open Hearth furnaces at night Hospital building in the foreground. Likely an official picture by plant photographer named Shafer in the 1950s, I worked with his son Paul at No 1 Caster in the 1980s. Rich Paskash: BOP Shop, No. 3 & 4 O.H. I worked #5 OH & BOP Shop. Robert Preskop: Back when Gary was a booming prosperous city of almost 200,000 population. |

|

| 1 |

|

| 2 |

|

| 3 |

|

| Kirk Martinsen posted, cropped USS GARYS WORKS 9/10, Blast Furnace row, Name the furnaces if you can. Second post to correct the picture. Rob Lowther: 4,6,8 14 not in the pic Mirko Ivanovic: 4 south most [farthest] 6 middle 8 north Michael Sweeney: 8 is a smidge smaller than 4 and 6. 4 less tuyres. Tim Armenta: Oldest ore bridge A1 Mike Demkowicz: Nice view #8 ore bridge. John Fiala: Mike Demkowicz #9 lost in a tornado/waterspout! Skip Burch: #8 is the only furnace with the dust catcher on the west side. James Mcclure: Looks like ore yard filling up for winter. Here we go, lower right #8, next in the middle #6 and in the background #4. All that are left of original 12. Oh yes 14 is just to the right out of this picture. Keep on casting. 🔥🔥🔥🔥 |

|

| 3D Satellite |

|

| Lee Kidd Jr. posted US Steel Gary Works. #8 Blast Furnace. Richard Durham: Slag going into pit and excessive gas being burned. Can’t see the flame during daylight. Scott Gracie: Is the blue flame to the right burning off excess coke gas? What is it referred to as? Bob Halko: Scott Gracie It is a flair stack burning excess producers gas (blast furnace gas) that the Load Dispatcher could not find a home for so it's flared. Burning money but only about 90 BTUs per cubic foot. Scott Gracie: Bob Halko , Yes, " flair stack". Thanks for the refresher. I couldn't recall the term for it to save my life. 👍 Brian Lucas: The tint of yellow means they have a leaking tuyere, Bosh or stack plate. Water in the furnace somewhere |

|

| Bobby Stephens commented on Lee's post Almost got the same pic, just with a loader digging in the pit. |

|

| A comment on the video, cropped (name deliberately omitted) |

|

| Joey Lax-Salinas commented on Kirk's post Here is nearly the same aerial view, but as it looked in 2014. |

From their web site:

Gary Works, U. S. Steel's largest manufacturing plant, is situated on the south shore of Lake Michigan in Gary, Indiana. Comprised of both steelmaking and finishing facilities, Gary Works has an annual raw steelmaking capability of 7.5 million net tons.

Sheet products, strip mill plate in coils and tin products are manufactured at Gary Works. Hot-rolled, cold-rolled and galvanized sheet products are produced for customers in the automotive, metal building components, home construction and appliance markets.

Tin products are also produced at Gary Works. These products are used by customers in the container industry in the manufacture of food and beverage containers, aerosol cans, paint cans and pails, and more.

United States Steel Corporation

Gary Works

One North Broadway

Gary, IN 46402

(219) 888-2000

PRODUCTION FACILITIES

- Four blast furnaces

- Three top-blown basic oxygen process (BOP) vessels

- Three bottom-blown basic oxygen process (Q-BOP) vessels

- Vacuum degasser

- Three ladle metallurgy facilities

- Four continuous slab casters

- 84" Hot strip mill

- Hot-rolled Temper mill

- 80" and 84" Pickle lines

- 52" 6-Stand and 80" 5-Stand Cold reduction mills

- Electrolytic cleaning line

- Three batch annealing facilities

- 38" Continuous annealing line

- 80" 1-Stand, 48" 2-Stand and 84" 2-Stand Temper mills

- 48" 2-Stand Double cold reduction mill

- 37" and 46" Electrolytic tinning lines

|

| Nathan Stephens posted U.S. Steel Gary Works - 1959 Elektrika Sign posted Granddaddy of them all. U. S. Steel Gary Works in the 1960’s / 1970’s. 12 Blast Furnaces and 35,000 employees.

How many furnaces were running when that place was full tilt ?

Author

12. US Steel had another plant in nearby South Chicago that was almost as big as Gary. Called US Steel South Works. Largest Corporation in the world for decades US Steel was.

After the downsizing of Sparrow’s Point following its peak of 8.1 millions tons after 1958, Gary resumed its place as the largest mill in the country.

|

|

| 1 |

|

| 2 |

|

| Michael Reyes posted Abdu McCully: Definitely Gary Works looking east from the 1 Bop Shop. |

|

| INDUSTRIAL CULTURE & PHOTOGRAPHY posted Back in the day when steel was on the peak. Paul Sequeira, Gary Works, USA, 1973 Chris Knoxhill I thought steel was in the dumps during the 70s? Also, what railroad served this plant, the penn central or chessie system? INDUSTRIAL CULTURE & PHOTOGRAPHY The recession came in late 70´s. This is 1973. No idea about the railroad, sorry. John Slowikowski Chris Knoxhill the first real blow came with the Youngstown sheet and tube on sept,19 1977 and was like a chain reaction after that. Dennis DeBruler EJ&E was owned by USS and connected all four Chicagoland works: South, Gary, Joliet and Waukegan. It was a belt railroad around Chicago and connected with all of the trunk railroads. When CN bought it, a new company, Gary Railway, was formed to own and operate the tracks in the Gary Works. https://www.transtarrail.com/.../fY6xDoIwFEV.../ |

|

| Nick Hart posted It's business as usual at Blast Furnace #4 as a pair of Gary Railway SW1200's shove on a load of coke. Gary, IN 10-03-23 Craig Cloud: Launch point? Nick Hart: Craig Cloud Great Lakes Cafe. |

|

| Fourth of eleven Gary Works photos in a Gallery |

|

| 1 |

|

| 2 |

|

| 3 |

|

| Eric Maul posted Gary Works my place for 30 plus |

|

| Marco Flores posted a picture from an iron worker friend Andrew Urbanski commented: "EJ&E on the hi line? interesting!" Forgotten Railways, Roads, and Places also posted Forgotten Railways, Roads, and Places posted again |

|

| Satellite |

|

| Bird's Eye View |

|

| Bird's Eye View |

|

| Chip Douglas posted, rotated and cropped Frank Fransioli: Thanks. What I liked about working there, aside from just the incredible, massive scale of everything, was that as you moved from East to West, you could follow the process of making steel, from raw materials through molten metal to rolling mills and finished products. I was grateful for the orientation that we received in our first few days and the rich diversity of the people I met there. John Slowikowski: Still remember getting super lost in there looking for door 800 the first time I went there. |

|

| Steampunk Railroad posted US Steel Gary Yard Stoves and Furnaces 11, 12. December 1907. Calumet Regional Archives, Indiana University Northwest. |

|

| Tom Wells posted Gary Works in a South Shore 1920s promotional poster. These are not copyrighted, amazingly. This was the view of sunrise I saw from the 200 ft level of the number 1 Caster. Wish I had taken pictures myself. |

|

| 1 |

|

| 2 |

|

| Kelly commented on his post |

|

| safe_image for U.S. Steel restarting another blast furnace at Gary Works as steel industry recovers Doug Lanum I'm curious, how do they start a blast furnace from cold and how long does that take before they're up and operation? Stacy Mays Doug Lanum If I remember correctly, it takes 3 or 4 days to get the refractory in the furnace and stoves warmed up enough to start letting some wind and coke in. Then once they get to that point, every few hours they take the furnace off and open a couple more tuyeres. That depends on how well everything is heating up. It can take a few days once they start charging to get good iron. James Clutch Raber Doug Lanum we were told 3 weeks to heat up the stoves. Phillip Hawkins I have only witnessed a restart from idled furnaces. That is where the brick lining is kept warm to protect from being damaged . The only time i have ever witnessed a cold restart, is when they hzve done a complete reline or rebuild of the furnace and stoves. That does usually take 3- 4 weeks depending on inspections and preassure t ets all going ok. They have had to cool back down before and make minor repairs before start up. Mark Sparky Eddleman Doug Lanum years ago they just put wind to a stove and left all the wooden scaffold inside and let her go. Now using temporary heaters that increase the temp in small increment each hour to cure the gunite and brick mortar. Stacy Mays Phillip Hawkins Like I said earlier, if I remember correctly. It's been a really long time since I was involved with a cold start. Like you the last few were after a rebuild. The question I haven't seen is was the furnace banked? And how long ago was that done? I think a banked furnace can stay warm for 6 or 8 months. Mark Sparky Eddleman Stacy Mays we restarted a furnace here in granite city a cpl years back that was banked for 2.5 years right after a reline. They cured the gunite with a gradual heat up using temp burners then cooled it off and banked it. It was retired using the same process as if it were just relined. Slow heat up on stoves and furnace with temp heaters the loaded some ore and coke when wind was put to the stoves. The other furnace was banked at the same time but it was making iron before banked. They kept it from getting too cool in the winter with steam. I can tell u that the bottom of th shell is 20ft below the tuyere deck and in 25 years I have only seen it completely removed one time. We have excavated a 5x5x5ft hole inside at the tap hole to place the rebar cage known as the doghouse and even after being down 2 months the coke that was down there was still warm and with the help of some air blown on it became very hot. When we took the bottom shell out in 95 I was told that the heat down there was coming from what is known as the salamander. It could stay hot for months when out of service. We always clear the furnace of slag basically by hand pushing it out of a tuyere hole with the jacket removed. Bigger pieces are cut down to size using oxygen lance and removed. The floor is usually dug down maybe a cpl feet below the tuyere holes except for the doghouse. [They are restarting the second of three blast furnaces as car companies recover from Covid-19. Operations in Minnesota, Michigan, Ohio and Texas remained idle.] |

Update: 9:26 video, no BOF scene.

|

| Al Miller posted Pickets representing the National Maritime Union use a launch to take their message to crewmen aboard the James A. Farrell, which was docked in South Chicago on Sept. 20, 1946. This is an Acme Photo Service photograph. Fred Miller II: What I would give for those forward cabins! |

|

| Steven Harverty commented on Al's post A slightly different version of the same photo mere seconds later |

|

| Robert Campbell posted The Henry H. Rogers is shown at Gary, Indiana in July 1965. Photo by John Vournakis. Joe Shaver: I worked at Gary Works in the early 90s-when I was casting supervisor I was invited for tea aboard the Callaway while it unloaded. Marvelous middle of the night experience. We always had to open the water bypasses when the ships came into the slip because if we didn’t it would clog up our intakes. Because of this, I always knew when they were coming in and I would always go down to watch if I had time. Dale Belles: my parents and grandparents would tell me that sulfur smell was the smell of money (their retail business went the way of USS). Good times meant good times for all of Gary. [So sulfur was what I smelled when I drove into the orange cloud over Gary when I was westbound on the Indiana Tollroad.] James Torgeson shared US Steel's 601' Str. Henry H. Rogers is shown at the Gary Works in this 1965 view. Needless to say, she was a coal-burner! The structure above her is the conveyor system from the sinter plant, which was across the slip from the steelmaking operations. The Rogers was built in 1906, last sailed in 1972, and was scrapped in 1975. Mark Goodrich: Check out the Hullets and all the ore bridges. There were more ore bridges south of the conveyor also. Stephen Schroeder: [Currently] There's only one bridge crane (8 bridge) north of the conveyor going over the slip and 2 south of it 1 and 1A bridge |

|

| Brian McCune commented on Robert's post ‘68 from the Crawford, after spinning on forward wire that was on the self releasing spile on the dock! |

|

| Al Miller posted Henry H. Rogers opens the port of Gary on April 10, 1955, with a load of 10,300 tons of iron ore loaded in Escanaba. This photo is from the May 1955 issue of Pittsburgh Sidelights. [Escanaba was owned by Cleveland Cliffs instead of US Steel, but its port was open (no ice) this early in the season.] |

|

| Al Miller posted This photo of Eugene P. Thomas at Gary has something for everyone. It graced the back cover of U.S. Steel News magazine in June 1937. With the perfectly placed locomotive, conveniently located workmen and dangling buckets, I'm guessing noted industrial photographer Robert Yarnall Richie had carte blanche from the company to set up this photo. |

|

| Bill DuFault posted

Where is ‘she’ located?

Gary, In

[Note the two 25 hz power towers in the background. Although the tops don't appear to be yellow.]

|

|

| Amanda Wilke posted 8BF Gary Works, Indiana. At the end of a 60 day outage. Billy D. Wadkins: Worked on it in 1995 when they blew the top off it. Man that was a hot summer! James Steinhauer: Billy D. Wadkins did the ever find their small bell? Billy D. Wadkins: James Steinhauer It was a bleeder not the bell. They found the bleeder weeks/months later in the ore pile east of the furnace….. |

|

| Luke Malin commented on his post of a Flickr photo [Concerning the heavy duty "grey car:"] Jim Jamrus: Not 100% sure but I think it's used to move the BOP shop ladles out when they need to be re-lined with new refractory brick.....Harbison-Walker used to have a shop on Clark Rd in Gary that would re-line both bottle cars as well as the ladles used in the area mills...it was local to EJ&E so non-AAR interchange cars could be used to reach it. |

|

| Douglas Drexel Mitchell posted Yellow-bird headed to Q-Bop with a load of molten steel. 5-11-24 Gary, Indiana |

|

| (This photo was supposed to be further up in these notes. But a Google bug put it at the bottom of these notes. Instead of wasting my time working around a bug that I reported weeks ago, I leave the photo here as a monument to Google's bug.) David Flood posted

My grandfather in the middle. Worked at Gary Works from 1922ish to 1970ish

He hated having his picture taken so not sure how this happened. Wish I knew more about photographer and could find other photos they took.

Bubba Dubs There were multiple company photographers on US Steel payroll back then, so it could’ve been any one of them. |

|

| Raymond Boothe posted Aerial view of the USS Gary Works No. 14 blast furnace (unkn/Dr. Raymond Boothe collection). |

|

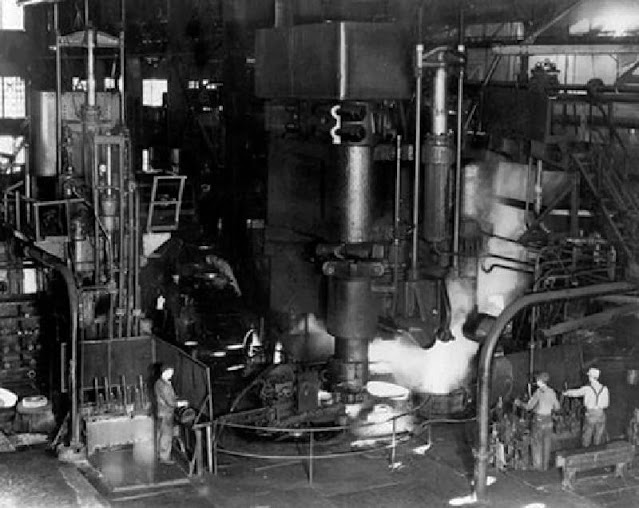

| Raymond Boothe posted Indiana Steel Company (Later USS Gary Works)-1917: View of the Bessemer Converter Shop (IU Collection/Dr. Raymond Boothe B&W repair). |

|

| Raymond Boothe posted Indiana Steel Company (Later USS Gary Works)-March 3, 1916: View of the No. 1 Open Hearth Shop Charging Machine (IU collection/Dr. Raymond Boothe B/W repair). |

|

| Raymond Boothe posted USS Gary Works: Forging railroad wheels in the wheel shop (Harvard Business Collection/Dr. Raymond Boothe B&W enhancement). |

|

| Dale Giolas posted USS Gary Indiana, 1957 taken by my father John Giolas. John Mabin: Can't beat standing on a pouring platform where you froze on one side and were toasted on the other. USS Gary Works No. 2 Q-BOP (if I remember correctly) and 46" Slab Mill. |

|

| 1 |

|

| 2 |

|

| 3 James Mcclure: This building on the right is still in use as division office for South Blast. Jim Reinhold: South end of Fab D |

|

| 4 |

|

| Joe Linvill posted Here is my view. Rock Gervais: We local 374.Boilermakers have built and worked on all of the USS blasts. My first job as an apprentice was one the 13 furnaces at that time. American Bridge. Douglas Warner: USS Gary Works 4, 6, 8 and 14 looking west worked there almost 20 years ago... |

|

| Jonathan Bowman posted [When I first saw this photo, there was a comment that identified it as #2 and #4 at USS Gary Works. But when I went to copy it, that comment had been deleted. I guess the USS photo cops outlaw commenting as well as taking photos.] |

|

| Dale Harboth posted Gary Work Hot side |

|

| Dennis DeBruler commented on Dale's post The building in the foreground now has a lot more ivy on the wall. |

|

| William O'Neal Stringer posted a story in addtion to this comment: I ran this old cow and calf set up for many years in the Gary Mill. Using the electrical power from the engine it cuts in half the speed but generates a lot of pulling power. This locomotive was built in 1939. This is the unit they would use to shake the coke cars. |

|

| Al Miller posted On May 30, 1974, Cason J. Callaway departed the Duluth DM & IR ore docks with its first cargo since being lengthened by 120 feet at Fraser Shipyards. The Callaway carried a dock record 26,634 tons of ore for Gary. At 767 feet, she was well received by the fleet, which was looking forward to the similar lengthening of the Anderson and Clarke at the end of the season. (From Sidelights -- July 1, 1974) This U. S. Steel photo shows the Callaway shortly after it returned to service at its new length. I don't know whether this was shot on its first trip. Tony Gatliff: I thought they converted them to self- unloading when they lengthened the “AAA”’s ? When did they boom them?Craig Barteldt: 1982 Stephen Schroeder: US Steel looks the same |

|

| Ryan Mihalak posted Given the fact the billboard says "Company", this must be a pre-1952 photo. Image courtesy the US Steel Gary Works Collection (1906-1971) of Indiana University. http://webapp1.dlib.indiana.edu/ussteel/results/item.do... Jeff Milligan: . . . Fairless is of the same Vintage as the present day Alpena . . . sister type ships of the day . . . Isaac Pennock: still winding around with the wires to this day |

|

| Robyn Riley commented on Ryan's post I have the builder’s plate from her. |

Definitely a first for me, I’ve unloaded into other ships before, but not from one footer to another. We rafted both 1000’ ships together, M/V Edgar B. Speer and M/V Edwin H. Gott. Customers needs were met and all was accomplished safely.(The Speer unloaded into the Gott, the Gott unloaded onto the pile in Gary)These sister ships have been first for a few things already this year, truly an interesting and exciting start to the season.

In this unique view in the slip at the USS Gary Works, the 1004' Edgar B. Speer (1980), at right, unloads iron ore pellets into her fleetmate, the 1004' Edwin H. Gott (1979). The Gott is then using her 280' boom to distribute the Speer's pellets deep into the plant's ore yard. Apparently there's an issue with the receiving hopper that the Speer needs for her short shuttle boom, and this is the solution. Both vessels originally sailed for the USS Great Lakes Fleet, and are named for former USS Chairmen. The fleet is currently owned by the Canadian National Railway.

|

| 1 |

|

| 2 |

|

| 3 |

|

| Mirko Ivanovic commented on James' share Looks like speer was done offloading Kyle SStover: “No coil barges today we’re gunna need y’all to shovel the transfer house all day” |

|

| Fred Newman posted US Steel, Gary Works, 1960 James Torgeson: Looking across multiple RR main lines straight down the slip to Lake Michigan. Anthony Letnich: 12 Blast Furnaces and 35,000 people. |

|

| Eric Hansen posted # 2 battery US Steel Gary works 1958 |

|

| Eric Hansen posted Coke side #6 battery USS Gary works March 1966 |

|

| Eric Hansen posted #6 battery Gary works 1966 |

|

| Mike LeDuc commented on Eric's post Q-BOP, about the same time... In goes the scrap, and maybe some snow and ice. I'll ask James if I can take a pic. |

|

| Mike LeDuc commented on his post then goes the hot metal. |

|

| Mike LeDuc commented on his post ice makes it go boom. |

|

| Thomas Boswell posted Late 1980's view of Gary Works #7 three-meter coke battery. Seen is top side and pusher side. Bi-products dept. In the background. Coal was loaded into the Larry Car shown topside, from the coal bunker, and then the Larry Car would charge the oven through several charging holes. |

|

| 1 |

|

| 2 |

|

| Thomas Boswell posted Mixed C&O coal loads at the Coal Processing plant at U.S.Steel Gary Works mid to late 1950's. Randall Hampton shared |

|

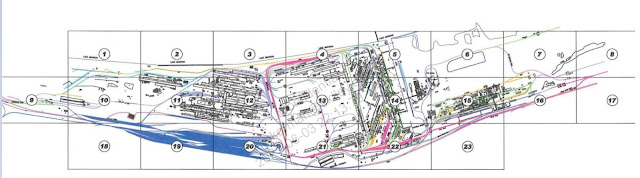

| Brian Fattore posted Current Gary Works plant railroad map from 2021 STB filing. [After CN bought EJ&E, a new railroad was split off to operate the tracks inside the mill.] Cory Donahue: What is funny is that this is the map they give the poor truckers that come in the plant and basically tell them good luck. The amount of times I have been stopped by a lost trucker and looked at this map is ridiculous. They are given no direction whatsoever as to where they need to go. Kyle Miller: Only one gate they can fit under to. Anthony Zacchero: USS Homestead was just as bad probably worse. Also the receiver in the Storeroom/Warehouse was an ornery cuss. He was so mean/rude to those drivers it was terrible. |

|

| Thomas Boswell posted Gary Works Coal Handling rail facilities from the early 1960's. Empties from the car dumper on the left ready to return to the Pocahontas coal facilities in West Virginia. On the right are coal loads from the Corbin coal washer in Corbin, Kentucky. |

|

| Tom Cera posted U. S. Steel Gary Works blast furnaces under construction - circa 1907. [A comment points out the horse drawn wagon.] Kevin Nelson This website has a lot of Gary Works photos. |

|

| Comments on Tom's post |

|

| Julez Stefanik posted My ”Then and Now” post |

|

| Dennis DeBruler commented on Julez's post If they repainted it, what did they do to keep it from becoming black again? https://www.google.com/.../data=!3m1!1e3!4m5!3m4... Pamela Goins: They haven't painted that as of yet. Not sure if they will. |

|

| Rocky Black posted Mold yard was a crazy place to work. Art Wright: Phillip Claxon Could be Gary, layout and stripper buildings, exactly the same. |

|

| Raymond Boothe posted USS Gary Works-1930: View of Open Hearth Shop No. 4 (IU collection/Dr. Raymond Boothe B&W repair). |

|

| Raymond Boothe posted United States Sheet and Tin Plate Company (later USS Gary Works): Employees working United tin plate machines (unkn/Dr. Raymond Boothe collection). |

|

| Raymond Boothe posted Indiana Steel Company (later USS Gary Works): Coke push at Battery No. 6 (IU collection/Dr. Raymond Boothe B&W repair). |

|

| Raymond Boothe posted Indiana Steel Company (later USS Gary Works-December 27, 1914: Rolling plate at the plate mill (IU collection/Dr. Raymond Boothe B&W repair). |

|

| Jim Prrfan posted [Some comments identified this as Gary Works instead of South Works.] Jim PRRFan collection [It looks like an ingot train next to the building.] |

|

| Aaron Collins posted Gear swap a few years ago. Gary Works roughing mill gearbox. William J. Wiggins: 84 inch hot strip. Spent many years there-67-88. Got to see the first bars go through. 😎 Rich Paskash: I wonder what the gear ratio is, output speed & output torque. Bob Cvetichan: I worked at Horsburgh & Scott in Cleveland for 8 yrs. We made steel mill gearing like that. Sight to see, when heat treating and oil quenching : I did NOT appreciate picking up those bull gears and weaving around all the stuff in the motor room with that horrible little crane. Jim Reinhold: Scott Dailey you mean the crane that took 20 minutes to go from one end to the other. Rudy Fernandez: Nice, high speed pinion, intermediate gear and bull gear. I have had a of time scraping babbitt at CSI. [Some comments speak will of Cleavland-Cliffs.] |

|

| Anonymous participant posted #8 furnace Gary Works Dave Willey: I’ve been near that furnace many times, but I don’t recall trees. John Travers: Gary Works and a lot of other steel plants are letting weeds and trees grow within the plant confines since the late 1980s and to me it's just laziness and neglect on the part of the plant maintenance crew. It's also because of so much empty space due to so many furnaces/mills being demolished with nothing to replace the resulting empty spaces. It's a pigspen. John Travers: No.8 was rebuilt to its present appearance in the late 1950s as a Koppers rebuild with the single downcomer, as were sister furnaces numbers 10, 11, and 12 in 1957-59, also at Gary Works. The rebuild furnaces had a scrawny, wimpy looking appearance, compared to the more robust-looking McKee built furnaces at nearby Indiana Harbor. Joe Tarowsky: Ok so what is the roofed building attached to the furnace? James Mcclure: Joe Tarowsky. This the Distrbution Control for PCI, PULVERIZED COAL INJECTION SYSTEM. Started this about mid 1990's. 🔥🔥🔥🔥 [Some comments talk about HBI allowing EAFs to make blast furnaces obsolete. HBI can also be used to reduce the CO2 emissions of blast furnaces. Of note is a comment by Bill Flanagan: The process uses natural gas and high temperature to reduce the Fe2O3 and Fe3O4 from iron ore to Fe. Then it is hot pressed into briquettes. In a blast furnace the reluctant is CO from burning coke to do the reduction so this so called green process exchanges coal for natural gas.] |

%20Steel%20Mill%20Pictorial%20_%208%20furnace%20Gary%20Works%20_%20Facebook.png) |

| Comments on the above post |

|

| Carl Kaszycki posted #8 Gary. James Mcclure: Gary D Ingram It has 16 tuyeres. Not sure of hearth diameter. But it's the smallest of the 3 South Fces. Gary works [Some comments talk about this is the one that fell over in 1995. No one was hurt and it was running again in 5 months. This is evidently a photo during a current rework in 2022.] |

|

| 1, cropped |

|

| 2 |

|

| 3 |

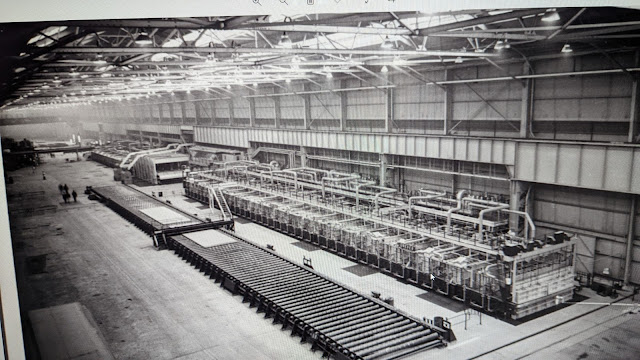

Dennis Taylor posted two photos with the comment: "Plate Mill Heat Treat, USS Gary Works"

|

| 1 |

|

| 2 |

Dennis Taylor posted two photos with the comment: "210" Plate Mill, Gary Works."

|

| 1 |

|

| 2 |

Dennis Taylor posted two photos with the comment: "210" Plate Mill housing and #2 Side Shear Gary Works."

|

| 1 |

|

| 2 |

|

| 1 |

|

| 2 |

|

| Nicholas Maggia shared a link Rendering of $60m pig iron caster being built at U. S. Steel Gary Works (Graphic: United States Steel Corporation) R Jim Echlin: I’m seeing a lot of comments which I don’t believe accurately depict what this is all about. My take on it is that the new pig caster is to be used to cast pigs from blast furnace iron allowing greater utilization of existing blast furnace capacity while providing melt stock for the Big River EF furnaces. This does not eliminate or reduce the use of the Gary Works BOFs. Casting pigs from blast furnace produced iron is far from a new process but to my knowledge has not been done at Gary at least in the recent past. Gary Rigg: R Jim Echlin It is going to be another outlet for the iron the iron to go to so the blast for this is can run more efficiently instead of instead of going up-and-down and up-and-down it will be able to run more efficiently. R Jim Echlin: Big River’s approach to steel making is based on the approach developed by Nucor and introduced in the 1988-89 time frame at the Crawfordsville plant. It is basically the “mini mill” continuous process that take EF melted steel from liquid directly to finished hot rolled coils. Stacy Mays: At one time, almost every plant that had blast furnaces had pig machines. Bob Featherstone: How will they ship the iron to Big River? Pano Theodoratos: Bob Featherstone Barge like they’ve been doing. Bob Yanik: About ⅔ of the pig iron used in the US comes from Russia. They might be trying to get get a chunk of it. David Horn: Brazil, Russia and formally Ukraine had operational pig castors.. Ukraine’s pig castor got demolished in the war and most countries are not taking Russian exports. Leaving Brazil as the only pig iron producer. US Steel will be the next player. Mike Matthes |

[Several comments speculate that Mon Valley will be shutdown after USS gets their new EAF at Big River working.]

|

| safe_image for these notes Just found great link with images and history of GaryWorks with detail I never knew. Apologies if duplicate. I continue to be surprised when I discover a new album ! Michael Siola shared [Some comments indicate that it used to be a very dangerous place for women to work in. They had to be escorted from the parking lot to their work stations by security personal.] |

|

| safe_image for U.S. Steel casting pig iron in major milestone at new Gary Works facility "It is supplied by iron ore from U.S. Steel's mines in Minntac and Keetac in Northern Minnesota's Iron Range. It will produce up to 500,000 tons of pig iron a year, producing 50% of the metallics needed for the steelmaker's new Big River Steel Works." Calum Learn: Is it a true pig caster or a granular iron caster? |

|

| Sam Foster posted Drone shot I took of some torpedo cars coming out of one of the mills at Gary Works last Sunday. One of Gary Railway’s SW1200s in the lead of the train. 1/8/23 Video from Gary Works and also Inland Steel: https://youtu.be/8cdo6XdeJsY Keith Friedlund: This looks like No. 1 BOP Shop at Gary. That shop was built in the late 1960’s. Cutting edge tech. at that time. Zac Fuller: George Munoz it's coming out of desulf at the 1BOP. Matthew Mrzlock: I watched the full YouTube video. The first mill recorded is actually the old LTV/ISG mill not inland. It is now currently Cleveland Cliffs Indiana Harbor West. The blast furnaces in the video is #3 & #4 on the west side and #3 steel producing. You can see the old 84” Hotmill in the background half diminished. Sad sight to see. Would love to see more of those demolished buildings if possible. Randy Jureczko: I definitely don’t miss rerailing them. |

|

| Johnny Hansen Photography posted It’s business as usual at U.S. Steel Gary Works plant, as the Gary Railway is viewed with a former Elgin, Joliet & Eastern SW1200, a slug set, and a cut of molten steel bottle cars that are in the process of being loaded at one of the blast furnaces, the 1BOP shop on a beautiful morning. Photo Date: March 8, 2025. Johnny Hansen shared |

|

| William Arthur Timmerman posted US Steel Gary Works 84” Hot Strip “Slab to coil” David Hope: The 80" coils we made in Cleveland were never that red hot once they were in the coiler. William Arthur Timmerman: David Hope this was a experiment we were trying to run 1” plate that day. Not a normal thing. Robert Jenkins: At the 80' Hot Strip at Burns Harbor, we had to band hot coils for shipment to Ford. The job sucked as you could barely walk at the end of the 12 hour shift. You'd literally drink gallons of fluid, and not pee one time!!! William Arthur Timmerman: Robert Jenkins this is after 2016 and they installed automatic banders and a robotic coil marker. [Some comments indicate that the fresh paint job indicates there is going to be tour.] |

|

| 1 |

|

| 2 |

|

| Kajal Chauhan posted Out with the 3 old 3,500 hp main drives and in with the new two 9,000hp motors Gary works. Mike VanVleet: USS Gary Works. 84" Hot Strip finishing mill James Neely: What's the voltage and amperage rating on 9,000 h.p. motor, beside unbelievable? Terry Michaels: James Neely With a Google search I found a Toshiba 9000 hp that ran on 4000 VAC 3 phase, full load current is 1121 Amps. Brian Olson: This pictures was posted a couple months ago. I asked the question if the pinion / bull gear and pinion stand gears were replaced but did not get an answer. Maybe you know. That is a significant jump in power output and I have a hard time believing the original Blawknox gearing could handle that increase in power. Just curious. Dennis Fortener: Brian Olson actually this photo is a few years old. Stand # F-3 was installed 3rd quarter 2022. ( No gearing changes were made). Zhee Fawzheea posted with the same comment Jacob Sides: Can we ban this person. They are obviously stealing other peoples posts |

|

| Kris Rossmiller posted What are these 2 similar buildings at Gary Works? [Several comments answered: "The mistake by the lake." Another common comment was "Carbon X." To summarize some comments: Carbon X was an $800m plant to make synthetic coke. One of the buildings is now used by a contractor.] Kris Rossmiller: What was Carbonix or Carbon X? Josh Tesreau: Kris Rossmiller it was supposedly a process to take less pure coal and still make high quality coke by blending the coal, making briquettes, then cooking them in a tunnel kiln that was 300’ long. It didn’t work well, trust me. Matt Shaggy Ziolkowski: Kris Rossmiller carbonyx produces a greener alternative to traditional coke called cokonyx. It still uses coal as the main ingredient for the product but the alternative does not have as much environmental impact. Among other things, gary works dumped $210 mil into this project before ditching it because buying coke from the free market was cheaper than using carbonyx. Randy Vanek: Billion dollar mistake by the lake. Old carbonyx buildings. The thought process was to make synthetic coal. It worked on a small scale but could never get it to work on a larger scale. Very sensitive subject to some people around Gary Works still. |

|

| safe_image for U.S. Steel restarts Blast Furnace #8 at Gary Works, photo by Jon L. Hendricks [Fortunately, my paycount has been reset so that I can read this article.] The furnace was shutdown last year in anticipation of a recession. Instead demand is going up. One reason is that auto manufacturers are now getting the chips that they need for production. [They have also restarted #3 in Mon Valley Works on Jan 27, 2023. "Mon Valley Works primarily, but not exclusively, serves the appliance industry." [bizjournals]] |

|

| 1 |

|

| 2 |

.jpg) |

| 3 Before the skip incline was tore out all the way. |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| Zach Coen commented on Andy's post |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Sam Foster posted two photos with the comment: "A couple photos from a recent drone flight over Gary Works on October 1st. Figured the sunset would make for some neat shots of the mill. The Arthur M. Anderson sitting in the harbor was a nice bonus as well! Hi-Res links: https://flic.kr/p/2p8HhV1, https://flic.kr/p/2p8zXqL"

|

| 1 |

|

| 2 |

|

| Keith Stelter posted, cropped Summertime Lake Michigan view from the #14 blast furnace at USS Gary Works. To those asking, I'm guessing it was about 2013. I was just going through old pics. [According to some comments, #13 is now #14.] |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Fred Schneck posted Gary 13 [actually, #8] blew its top and launched it into Lake Michigan in 1995. Christopher Huber: Umm... that would be 8 blast furnace. I was out here on midnights when it blew... John Ray Maneno: Christopher Huber that's what I thought 13 was the mistake on the lake. Bob Clementi: Christopher Huber yes it was no 8. A year later 13 had a burn through. No 8 was may of 95 I think. Ed Boncela: Christopher Huber that’s why they welded ribs to all the oven tops. Robert Fickle: That was #8 and it was a myth that the top landed in the lake. The top actually landed on the hi-line tracks, I was there on the first contractor call out and put eyes on it. John Fiala: I heard that The EJ&E hi-line engine crew had to go back to the Subway to change underwear after this! Michael Kane: Just thinking who had a camera just laying around back then. Christopher Richard: how did it happen? David Freedom: Christopher Richard hydrogen explosion or overpressure explosion from a burden slip as I recall. Roger Maull: Those wheels up there had the date 1918 I believe. |

|

| Rick Kusbel posted Gary works 80" 5 stand coming out of an outage in 2021 with a fresh paint job. |

|

| 1, cropped |

|

| 2 |

|

| Ashanti Gillette posted Arthur M. Anderson at U. S. Steel Gary Works, Gary, IN. Photo taken 12/27/23. Jonell Pointer shared Ashanti Gillette also posted with the same comment. |

|

| Joe Mcallister commented on Ashanti's second post |

|

| Jessica Van Giana posted Richard Stepusin: Looking at this picture, I think that # 2 caster we installed in 1985. The area left of the water tower. The 2 stacks with the white smoke could be the spray chamber exhaust fans. Slabs went from there to the north side of the plant, by way of crest carrier down the lake side road. |

|

| 1 |

|

| 2 |

|

| 3 |

| |

|

|

| 0:59 video |

|

| 0:59 video |

Photos of Gary Works taken by plane this past Saturday. Was neat to see the Lake Michigan side of the mill, as my drone can’t go that far. Got lucky with Gary Railway moving some coke around as we flew by!5/1/25

|

| 1 |

|

| 2 |

|

| 3 |

A great place to work with good health benefits and pension. I retired from Personal Services dept. In 1996.

ReplyDeleteMy family and friends worked at the USS Tubing Specialties Plant when it closed in 1984. Does anyone have pictures of the plant?

ReplyDeleteWhat a resourceful update! I just explored this wonderful post and amazed with the informative update about US steel gary works. The knowledgeable focuses and the related photos beckoned me to stay tune to the deep of the article. I appreciate you for sharing such an useful update that can enrich the industrial revolution. Anyway, with the rapid growth of science and technology industrial advancements are also at the high end. In this regard I would like to mention about https://chittak-laser.com/product-category/pipe-bending-machine/ that is dedicated to ensure services including metal pipe laser cutting, chamfering, slotting, length measurement, pipe bending, pipe end forming, etc. Additionally, the continuous innovation and upgrading of products, they have also developed intelligent welding automatic production lines, which greatly improves production efficiency.

ReplyDelete