These notes focus on the powerhouse. The lock has its own notes.

Between Keokuk, Iowa, and Hamilton, IL, is Mississippi Lock and Dam #19. It also has a powerhouse. In fact, the powerhouse is why it was originally built, and this dam existed a few decades before the other dams were added to the Mississippi to improve navigation.

This dam is about a mile long, and it is rather hard to get a picture of the whole thing. It was the second longest dam in the world when it was built, and it is still the longest dam on the Mississippi river. But, by an historical marker park on the Illinois side, someone has cut the trees so that you can see most of the dam and powerhouse. (Unlike most river powerhouses, this one is perpendicular to the dam rather than part of the dam. That is, it is parallel to the shore.)

This dam is about a mile long, and it is rather hard to get a picture of the whole thing. It was the second longest dam in the world when it was built, and it is still the longest dam on the Mississippi river. But, by an historical marker park on the Illinois side, someone has cut the trees so that you can see most of the dam and powerhouse. (Unlike most river powerhouses, this one is perpendicular to the dam rather than part of the dam. That is, it is parallel to the shore.)

|

| 20140613 0028c |

The organizers of the effort to build the plant searched for years before they found someone willing to attempt the project---Hugh L. Cooper, the engineer who had supervised the construction of the Niagara Falls plant. Since the customers they secured contracts with before they started construction were in St. Louis, the project was also the first to use high-voltage transformers and transmission towers. The Army Corps of Engineers received the lock for the 6-foot (9-foot?) navigation project as a condition of the original construction permit.

When the powerhouse was built during 1910-13, the $25 million project was the largest privately funded construction project in the world. People came from all around the world to witness the construction and the town became known internationally.

Five photos that Lisa Ruble added as comments.

Between Nauvoo, IL, and Keokuk, Iowa, was the Des Moines rapids. The 11-mile stretch of river that falls 22 feet (28 feet in a different source) was the first major obstruction to travel on the Mississippi river. This drop in elevation provides much of the 38 foot head (distance between upper and lower pools of water) for the power station. See a St. Louis Post-Dispatch article for a photo by David Carson of one of the cast iron Francis water wheels that has been retired. (Starting in 2001 the turbines are being replaced with more efficient stainless steel turbines.[1]) This turbine was designed to use a small head but with a high flow rate as opposed to the type of turbine that is used in, say, the Hoover Dam. That article also has a picture of the 15 generators. (Use the arrow in the upper-right corner of the photo to access the other photos.)

Comparing David's photo in the Post-Dispatch article of the generator room with an historical photo shows that most of the manual controls are still in place, but they are no longer used. All of the electrical components of the plant have been replaced, but most of the mechanical and civil-engineering components are of the original design, if not fabrication.

The electrical changes include switching from 25 Hertz power to 60 Hertz and using computer-based controls. But much of the 110,000 volt transmission equipment that was developed for this project is still in use[1]. The highest voltage used by the Niagara project was 20kV.

The current use of the hydro power is as a peaking plant because a generating unit can be brought on line in a matter of minutes. Basically, open a gate and sync it to the grid. This allows the plant to be used when one of Ameren Missouri's baseline nuclear or fossil fuel plants has an unexpected outage or during "peak" periods of electrical demands.

Every arch in the dam had a spillway sluice gate. It has been rainy enough this summer that some of the gates are open. A close up indicates that they have several gates open a little bit.

Other photos I have seen of the dam seem to use just a few gates that are opened wider.

I wonder if they opened the gates wider than normal to get a publicity shot for their 100th anniversary of operation. Many of the photos don't have any gates open at all because the locking operations and powerhouse can handle the river's flow. In fact, each day the Army Corps of Engineers notifies Ameren Missouri how many of the 15 turbines that they can run that day.

I learned that the Iowa side has the wrong angle to see the gates at the top of the spillway. The next time I go, I'm going to have to explore the Montebello State Park because it has a better view of the dam's arches. But it is still hard to see the gate itself. And then I found a closeup of a single arch in the Google image collection.

I think the flow in this case is just leakage. The dam is 29 feet wide at the top, 42 feet wide at the bottom, 53 feet high, and 4460 feet long. The spillways are 32 feet high. There are 119 piers. Originally just the piers and arch were built to create a bridge. This minimized the pressure on the next cofferdam for the next pier. Then the spillways were added under the arches 5 feet at a time.

http://alongthemississippi.org/2013/08/07/how-to-be-alone-2/

1) Induction into the HydroWorld Hall of Fame in 2013.

2) Keokuk and the Great Dam, John E. Hallwas, Arcadia Publishing, 2001.

Update: Keokuk, Iowa Historians posted 25 aerial photos of the 1965 flood. I highlight the first one and another one that has a roundhouse.

When the powerhouse was built during 1910-13, the $25 million project was the largest privately funded construction project in the world. People came from all around the world to witness the construction and the town became known internationally.

|

| Marilyn Settles posted Lock and dam 19 |

It was the second largest

dam, the largest monolithic concrete dam, the largest hydroelectric

power plant with the largest cast iron turbines. (I'm still trying to

determine if the largest hydroelectric power plant would also have been the

largest power plant.) For comparison, the 1885 Niagara Power Station had 10 AC generators, each rated at 5,000 horsepower (3,700 kw)

or 50,000 horsepower. The Keokuk Power Station was rated at 250,000

horsepower and 142MW. Each unit can do 10MW, but there must be switching

equipment limitations that limit the plants capacity to 142 instead of

15*10=150.

But when the plant was opened for the 100th anniversary tour, a sign shows 150,000 horsepower and 150MW. The sign is obviously wrong because the horsepower should be more than the KW.

I hate it when websites break their links.

HydroWorld[1] has summarized the "firsts" for hydroelectricity:

But when the plant was opened for the 100th anniversary tour, a sign shows 150,000 horsepower and 150MW. The sign is obviously wrong because the horsepower should be more than the KW.

I hate it when websites break their links.

|

| https://www.practicalmachinist.com/vb/attachments/f19/82005d1374711815-tour-keokuk-hydroelectric-dam-imag0282.jpg |

| |

| https://www.practicalmachinist.com/vb/attachments/f19/82007d1374711859-tour-keokuk-hydroelectric-dam-imag0281.jpg |

|

| Tim Ice posted Keokuk IA. A government photo of Lock & Dam #19, the largest on the Mississippi River. Jim Colyer: Do any of the dams on the river generate electricity? Tim Ice: Jim, looking at this picture top to bottom: at top is the Illinois shore. The 119-spillway dam stretches across the Mississippi to the Iowa shore to the only hydroelectric power plant on the river.. 15 generators with 2 house generators. Further to the Iowa shore is the lock complex. Built in 1913. To the right is the Keokuk-Hamilton (Illinois) bridge, since superseded by a 4-lane non-swing span bridge. The original plant called for 30 generators, but during construction they found the flow of the river could only handle half that. Consequently only 15 generators were completed. |

The oldest hi-res topo map that I could find was 1964. The canal around the Des Moines Rapids would be long gone.

|

| James Long posted THE LOWER LOCK OF THE DES MOINES RAPIDS CANAL AT THE KEOKUK RIVERFRONT Many years before the construction of the current dam at Keokuk, river navigation between Montrose & Keokuk was hampered by what was known as the Des Moines Rapids. The city of Keokuk was built mainly on the business of LITERING OF BOATS travelling between St. Louis to St. Paul. Because of the Des Moines Rapids at this location, boats travelling upstream were forced to stop at the port of Keokuk to unload cargo to lighten the boat, the cargo was taken upriver to Montrose by road & the boat, sans passengers & cargo, was then safely able to navigate the rapids slowly. At times this process could take several days, therefore Keokuk needed several hotels to house layover passengers, its stores and restaurants thrived from the business of these passengers. In its heyday before the canal was built Keokuk was considered the most important port between St. Louis & St. Paul. Because Montrose was smaller, and boats coming downstream from St. Paul had to undergo this same process, most of those passengers also opted to come to Keokuk to await the arrival of and reloading of the boats at the Keokuk landing For many years, the 12 miles of rapids at Keokuk, Iowa, were the northern head of navigation. At high water the rapids were dangerous. At low water, they were impassible. Cargo headed up river or down river had to be unloaded from the boats and carried past the rapids in horse-drawn wagons. The US Army started to clear the Mississippi River as early as 1829. Lieutenant Robert E. Lee ran a project from 1831 to 1833 to remove snags and blast the largest rocks in the rapids. While this made running the rapids a little less risky, it did not solve the problem. A canal would be the solution, but that would have to wait until after the Civil War was settled. The Canal envisioned by Lee was approved and construction started in 1866. The canal was built along the west bank of the river. Starting at Keokuk, a w |

- Longest monolithic concrete dam;

- Largest privately-funded hydropower construction project;

- Largest turbines ever constructed;

- Heaviest rotating weight suspended on a single bearing;

- Largest penstocks;

- Largest inland dry dock;

- Only pneumatically-raised lock gate;

- Only commercial hydroelectric facility on the Mississippi River;

- First long-distance transmission line;

- First high-voltage transformers; and

- First high-voltage insulators.

Another notable feature of the plant - the generator rotor, turbine and shaft assemblies - may be the largest ever built. A single bearing that was four times larger than anything built previously supports each assembly. Engineers were uncertain a scale-up of the roller bearing would be adequate to provide the desired service life for the system. Only half of the turbines were installed with roller bearings. The others were installed using a new type of bearing that had just been invented by Kingsbury Thrust Bearings. These new bearings were so effective that they replaced all of the roller bearings at the plant within the following decade. After a century of virtually continuous operation, none has needed more than minimal repair.

[1]

|

| Lisa Ruble posted Powerhouse #19 at Keokuk, Iowa Between Keokuk, Iowa, and Hamilton, Illinois, is Mississippi Lock and Dam #19. It also has a powerhouse. In 1905 the U.S. Congress passed a bill granting the Keokuk and Hamilton Water Power Company the right to dam the river and construct a hydro-electric plant at the foot of the rapids and to build a new lock and dry dock to replace the canal which had become too small to handle the newer boats of the day. Construction began in 1910 and when completed in 1913 it was the largest capacity, single powerhouse electricity generating plant in the world. - Waymarking -- Clip of the hydroelectric power plant and dam at Keokuk and Hamilton on the Mississippi River: I took this photo from the Illinois side of the Mississippi River - March 2023. Eric Artman: Historic tidbit #3: The lock at Keokuk is MUCH larger than most Mississippi locks. At 110' × 1200' it's twice as long, enabling easier single locking than the "double locking" involving splitting a tow into two parts used at other locks. It also has a "lift" (level change) of 38 feet, almost four times the common 10' lift. (The impression on a small boater entering from downstream is not unlike a high school basketball team walking into UIUC's State Farm Center for the first time.) To top it off (bad pun fully intended) the upstream gate isn't a swinging pair of "miter" gates from the side, but a huge flat slab of steel truss work that drops underwater when the lock is full and raises like an upside-down guillotine when it's time to lower the lock chamber level. (The method used by boats to stay stationary during level change also differs, but it's just TMI. The boredom index is pretty high right now!)Lisa Ruble: Do they give tours of the plant? Amy Christy: Lisa Ruble not anymore 🙁 they closed down after 9/11 and you can no longer get as close as you could. When I was little my mom would take us right up to the fence by the lock and people on the Delta queen gave us their lotions and soaps as souvenirs and a barge once gave us real cotton from down south as it came through. They erected a large fence around the dam and blocked off the entrances so noone but employees can get in. You can only watch from the platform up onto of the control house for the locks or down by the south gages. Noone can go into the powerhouse anymore. I got to walk through a tunnel under the locks and the water trickled down the walls. When we came back we walked over the north gate and it was creepy too 😳 Amy Christy The powerhouse was a 'first' and still is for many things: - Longest monolithic concrete dam; - Largest privately-funded hydropower construction project; - Largest turbines ever constructed; - Heaviest rotating weight suspended on a single bearing; - Largest penstocks; - Largest inland dry dock; - Only pneumatically-raised lock gate; - Only commercial hydroelectric facility on the Mississippi River; - First long-distance transmission line; - First high-voltage transformers; and - First high-voltage insulators. Eric Artman: Historic tidbit #1: Although south of the principal boundary line, Keokuk and the surrounding territory north of the Des Moines River were left with Iowa when Missouri was admitted as a state so as to provide Iowa with direct access to the Mississippi River below the rapids that were submerged with the construction of the Keokuk lock & dam.Henry Hill shared Steve J Crile: In 1837 Lieutenant Robert E Lee helped to survey the rapids between Montrose and Keokuk. |

Five photos that Lisa Ruble added as comments.

|

| 1 Chief Operator's Room. Showing Control Board and Switchboards, 1914. |

|

| 2 Here is a look at the interior view of the powerhouse showing the turbines. |

|

| 3 Pedestal Containing Transmitter and Receiver, located near Generator. |

|

| 4 During construction. |

|

| 5 |

Between Nauvoo, IL, and Keokuk, Iowa, was the Des Moines rapids. The 11-mile stretch of river that falls 22 feet (28 feet in a different source) was the first major obstruction to travel on the Mississippi river. This drop in elevation provides much of the 38 foot head (distance between upper and lower pools of water) for the power station. See a St. Louis Post-Dispatch article for a photo by David Carson of one of the cast iron Francis water wheels that has been retired. (Starting in 2001 the turbines are being replaced with more efficient stainless steel turbines.[1]) This turbine was designed to use a small head but with a high flow rate as opposed to the type of turbine that is used in, say, the Hoover Dam. That article also has a picture of the 15 generators. (Use the arrow in the upper-right corner of the photo to access the other photos.)

|

| Reference link has broken |

The electrical changes include switching from 25 Hertz power to 60 Hertz and using computer-based controls. But much of the 110,000 volt transmission equipment that was developed for this project is still in use[1]. The highest voltage used by the Niagara project was 20kV.

The current use of the hydro power is as a peaking plant because a generating unit can be brought on line in a matter of minutes. Basically, open a gate and sync it to the grid. This allows the plant to be used when one of Ameren Missouri's baseline nuclear or fossil fuel plants has an unexpected outage or during "peak" periods of electrical demands.

Every arch in the dam had a spillway sluice gate. It has been rainy enough this summer that some of the gates are open. A close up indicates that they have several gates open a little bit.

Other photos I have seen of the dam seem to use just a few gates that are opened wider.

|

| WGEM |

I learned that the Iowa side has the wrong angle to see the gates at the top of the spillway. The next time I go, I'm going to have to explore the Montebello State Park because it has a better view of the dam's arches. But it is still hard to see the gate itself. And then I found a closeup of a single arch in the Google image collection.

|

| Hannah, used with permission |

I think the flow in this case is just leakage. The dam is 29 feet wide at the top, 42 feet wide at the bottom, 53 feet high, and 4460 feet long. The spillways are 32 feet high. There are 119 piers. Originally just the piers and arch were built to create a bridge. This minimized the pressure on the next cofferdam for the next pier. Then the spillways were added under the arches 5 feet at a time.

|

| http://www.practicalmachinist.com/vb/attachments/f19/82007d1374711859-tour-keokuk-hydroelectric-dam-imag0281.jpg

During the time of the tour, the river was well into flood stage. The gates were open and the water was really churning.

|

|

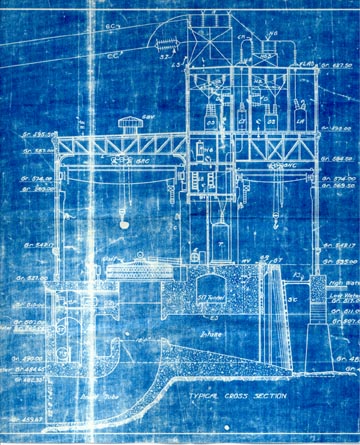

| Cross section of water raceway |

|

| https://www.practicalmachinist.com/vb/attachments/f19/82022d1374712794-tour-keokuk-hydroelectric-dam-imag0298.jpg |

|

| https://cgee.hamline.edu/rivers/Resources/Postcards/Keokuk1.html |

Impacts of the raised water level

The upper pool is 50% full of sediment. The sediment accumulation destroyed mussel beds that were upstream of the dam. This in turn destroyed the perl button business along the river. Actually, perl button is a misnomer. The buttons were made by punching them out of the shells.[2, page 26]Raising the level of the Mississippi River to create a 60-mile-long lake posed problems along the Iowa shoreline. The company wound up buying out almost half of three towns and moving the residents higher up on the bluff. Another challenge was raising the elevation of nearly 14 miles of track that belonged to the Chicago, Burlington and Quincy Railroad and ran along the Iowa river bank.[1]

References:

1) Induction into the HydroWorld Hall of Fame in 2013.

2) Keokuk and the Great Dam, John E. Hallwas, Arcadia Publishing, 2001.

Update: Keokuk, Iowa Historians posted 25 aerial photos of the 1965 flood. I highlight the first one and another one that has a roundhouse.

|

| a |

|

| b |

|

| Randy Sanderson posted Lock and Dam #19 [Note the powerhouse on the right.] |

|

| 1 of 10 photos posted by Jay Corbit |

If you like water power governor control theory and history, check out the oldwoodward.com history site.

ReplyDelete