(

Bridge Hunter,

Satellite)

All of the supplies such a rails and locomotives needed to build the original UP tracks had to be ferried across the Missouri River except in the winter when it froze solid and the ice was used as a bridge.

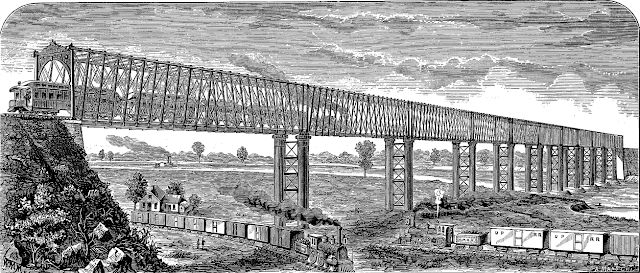

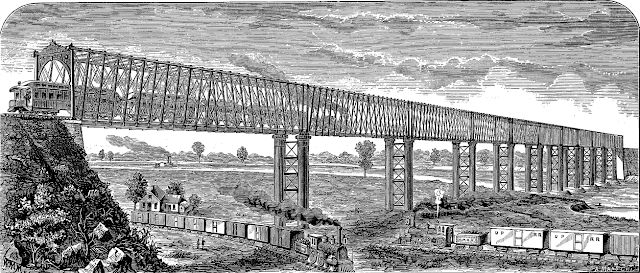

FIRST BRIDGE ACROSS THE MISSOURI RIVER

One of the most impressive of its day, the Union Pacific Railroad Bridge was built at a cost of nearly $2.9 million. The Grenville Dodge design was a half-mile long and featured 11 spans, each 250 feet long and 60 feet above water. Tubular-iron piers were planted in bedrock and supported with concrete and masonry. Severe winds damaged the structure in 1877. The bridge was repaired in 1887 and rebuilt twice, in 1888 and 1916. The completion of this bridge marked the true completion of the Transcontinental Railroad. [UP Timeline]

|

| Public Domain from eBooks, p. 246 |

The above picture and the following quotes are from

ENGLISH versus American Bridges written by The Railroad Gazette in 1874.

The Missouri River is the most difficult river on this continent, and probably of the world, to bridge, as its bed consists largely of shifting sand, which at most points, to the depth of sixty to eighty feet, overlies the bed rock, which, in connection with its frequent and rapid rises, causes change of current and deep scouring (often during founding, scouring out or filling in to the depth of forty feet in a few hours) calling into requisition all the resources of the engineering profession, and of the knowledge gained by experience, to overcome the obstacles, ten years since supposed to be insurmountable. [p. 242] (And I thought I sometimes wrote long sentences.)

The Omaha Bridge, crossing the Missouri River between Council Bluffs and Omaha, and connecting the Union Pacific Railroad with all Eastern lines, was designed and built by The American Bridge Company, of Chicago, in 1871, according to the following plan:

The substructure consists of one masonry abutment and of eleven pneumatic piers, one hundred and forty feet high, each pier being composed of two iron columns which are strongly braced between low water and bridge seat with horizontal and diagonal bracing. The cylinders, constituting the piers, were cast in sections eight and a half feet diameter and ten feet long, each with one and a half inches thickness of metal and provided with interior flanges for jointing the sections. These columns were sunk into the bed rock, filled from bottom to top with masonry laid in hydraulic mortar and thoroughly braced. Some of the piers are sunk to the depth of eighty-two feet below low water.

The Bridge is what is termed a "High Bridge;" the bottom chord being placed fifty-feet in the clear above high water, thus allowing steamboats to pass under it, and obviating the necessity for a draw span. It consists of eleven iron truss spans, two hundred and fifty feet each, making the Bridge two thousand seven hundred and fifty feet long. The trusses are twenty-seven feet eleven inches high from center to center of pins, their length being divided into twenty-two panels of eleven feet two inches each, placed sixteen feet ten inches apart in the clear between end posts. The material used is the best wrought iron for all the different numbers of trusses, except top chord and top lateral struts, which are all cast iron; there are two iron floor beams in each panel intersection suspended by means of hanger bolts from the bottom chord pins, and braced firmly by a system of lateral rods; a similar bracing stiffens the top chords; the struts and end posts are riveted work out of channel bars and plates, with cast iron shoes on either end to receive pins of bottom and top chords.

Approximate cost, $2,000,000. [p. 247]

No comments:

Post a Comment