|

| John Abbott posted |

|

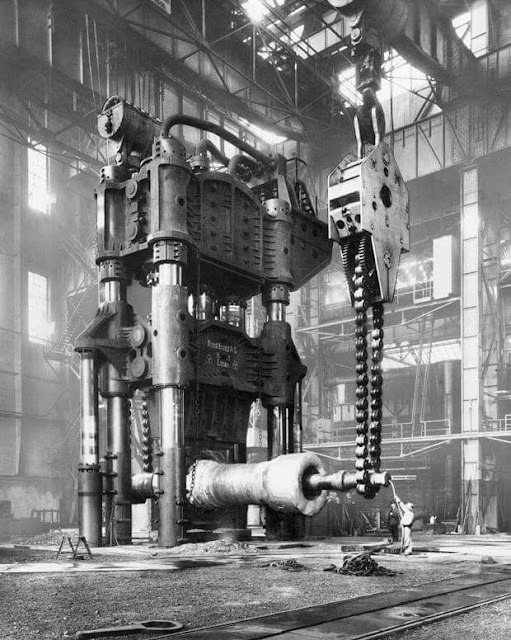

Paul Fisher posted Pete Von Tews http://www.zeit.de/.../industrialisierung-maschinen-fsPete Von Tews Steam-hydraulic forging press (15,000 tons) in the workshops of Friedrich Krupp AG, Essen, around 1928, unknown photographer © bpk / Bildagentur für Kunst, Kultur und Geschichte John Garrow http://www.france-metallurgie.com/.../Lehigh-Heavy-Forge... Richard Heikila Hopefully , we will again be a strong Nation and can make our own tools, machines, and parts again... The New San Francisco / Oakland Bay Bridge was made in CHiNA than shipped over here. Partly Because We did NOT have the Capability to make large Steel Parts for it's construction.... Mike Brady also posted 1928, Steam-hydralic forging press (15000 tons) |

|

| Bill Sparling commented on David Nagy's posting Bob Gaston Forging in the Krupp Works 1938 |

|

| Bill Sparling commented on David Nagy's posting another beauty from Russia this time |

|

| Bill Sparling commented on David Nagy's posting [Note the arrow pointing to a man. I did not realize so much of the machine was below ground.] |

Antonio Medina posted two images with the comment: "125-ton Steam Hammer Exhibited by Bethlehem Iron Co."

[I almost didn't notice the man standing under the hammer.]

|

| 1 |

|

| 2 |

|

| Sean Brady posted The 30,000-ton Schloemann closed die press from WWII. This monster, along with two 15,000 ton presses, helped create components for German aircraft production. After the war this press was taken back to the USSR and rebuilt. It is still in use today at the Kamensk-Uralsky Metallurgical Works in Russia. Note the people at the bottom for scale. Alexander Mihailovich: Looks like an "open die" press to me. Greg Carrow: Check out. The chain fall on that crane! Sakari Sahinaho: Press in pic ain't Schloemann's 30000 ton press. It is big press, yes. But ain't right one. Michael Richardson: Look at the dude on the frame above the material 🙂 Bud Kinney: So, my guess is this: it's actually a gravity-drop open-die hammer. They are rated by the falling weight of the ram. This ram is truly enormous and could weigh 100,000 to 200,000 lb. The rod used to lift the ram is too small in diameter to be a pushrod style, it only lifts the ram. These hammers are very precise and can last forever but, are slow compared to modern hydraulic presses. Yvon Patenaude: Hydraulic Lars Jensen: Some equipment ended up in Cudahy Wisconsin along with some engineers! Still running in the 70's while I was working there! Paul Grieger: There was the "Press Program" during the war. The Russians got the largest press in Germany, and the Americans got the two smaller presses. One of them went to Ladish in Cudahy Wisconsin (Milwaukee suburb). I am a semi truck driver, and have been there many times. They ground off the swast*kas in the mid 2000s because visitors were freaking out. The heraldic eagles are still there - in the castings. Look it up, it's a fascinating story. William Robbins: When you have really pressing needs. |

|

| Christoph Jonathan Freibler commented on Sean's post It is fascinating how these AI-images look different on different websites 😉 |

|

| Lothar Meyer commented on Sean's post [It is too bad that he didn't give more info about this press.] |

In Lost Illinois Manufacturing, I saw the following comment for their posting of this video:

Large tonnage presses (50,000 tons) are critical for forming large parts of modern aircraft frames. The U.S. after WW II had the capability to make this press (Mesta Machinery https://en.wikipedia.org/wiki/Mesta_Machinery) but when this Mesta press had to be rebuilt in 2008 no one in the U.S. was left with the capability to rebuild it so it had to be contracted out to Germany (http://www.siempelkamp.com/index.php?id=738&L=0). Another sign of the dangerous erosion of the U.S. national security due to the "free trade" policy of the U.S. Now, potential enemies such as China have taken the world lead in heavy press construction.https://en.wikipedia.org/wiki/Heavy_Press_Program http://blogs.wsj.com/…/under-pressure-the-10-story-machine…/ The machine is the biggest of its kind in the world. The biggest forge in the U.S. can exert only 50,000 tons of pressure, and is operated by Alcoa in Ohio. France has a 65,000-ton machine, and Russia has a machine capable of exerting 75,000 tons of pressure.

|

| Video of space-age forging (Wyman Gordon) Harvey IL location https://www.youtube.com/watch?v=bPbwu2ZsEtk&feature=youtu.be&t=1222 |

|

| 1:25 video Radial Forging in EICO, Credit: Hadi Ahmadi |

|

| Screenshot (-0:22) from video |

Danly die and press manufacture

|

| John Abbott posted Wyman-Gordon |

|

| John Abbott posted Large Steel Forging Press Alex Raphael Anyone have an idea of approx. how many forges of this size or larger are still operational in the US today? Joe Blowe There are multiple (5-10) 2000 ton plus knuckle style forging presses at aichi forge in Georgetown, ky. I put one of the 3000 tons in about 5 years ago. Mark Monson Based in Cudahy, Wisconsin, the 112 year old Ladish company has a vast forging operation including No. 85, the worlds largest counterblow hammer. This five story tall machine has a top and bottom ram, each one weighing 375,000 pounds. |

|

| Mike Raque commented on the above posting Mare Island CA (closed) |

|

| Alex Raphael commented on the above posting |

|

| John Abbott posted [It takes a big furnache to reheat the part.] |

|

| John Abbott posted areva Jerry Fleischman Notice he's stooping on a dirt floor, probably so as not to get to heavy a shock trough his body and being low would get less radiated heat. Thomas Bauza eleven inch hammer was the biggest I ever seen at Whyman Gordon Harvey Illinois [See the neck flange video for how they punch a hole in the middle so that they can then insert the round anvil to hammer against.] |

|

| John Abbott posted |

|

| John Abbott posted |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| Screenshot from Morrell's Forge Blacksmiths posting of a video. (I sure hope the link is permanent.) Our Samuel Platt Hercules in action. [Note his foot is on a pedal to engage the drive. There is a slot in the weight so that the hammer can handle thicker material. The bar is being hammered by just the weight. That is, the machine is not pressing the weight down. The crank and link is just letting the weight fall and then picking it up for another cycle.] |

|

| John Abbott posted Pneumatic Hammer |

|

| John Abbott posted This is my father operating the steam powered drop hammer in the forge shop out back behind the machine shop. Augustine Teng In 1988 I was watching a 10'' Pipe Flange being forged in Shanghai,China. I am amazed at how the operator worked the forge at the command of the smithy thru the hammer tapping signals. Raise,lower,hammer blows,stop to manouver job and tooling change etc. No vocal commands at all. Sad. There were no ear protections for the team.Richard Smith Steel billets forged into rings and machined into seals for the oil industry.Richard Smith They made some specialty rings that were plated most not. Out of all types of material, stainless, mild steel even copper. Up to 120" diameter. |

|

| Screenshot |

Patrick Gurdebeke posted three photos with the comment: "On a visit in France , I met the iconic famous dropforging hammer of Creusot Schneider (1878) standing as a statue on a roundabout..."

zzz

|

| 1 |

|

| 2 |

|

| 3 |

|

| Ub-88 posted A 12,000-ton armored plate press, at the shipbuilding firm of William Beardmore & Sons, Parkhead Forge, Glasgow. It was installed in 1912 and was used to shape ship's hull plates and gun turrets. James Torgeson shared |

|

| Collision Chronicles posted Vintage Giant Auto Body Punch Press Robert Paine: Press brake not punch press. Fun to tear down and relocate. |

|

| GMPhotoStore posted Large parts vehicle parts like this 1950 Oldsmobile hood are made in huge stamping presses at one of GM’s Metal Fab Division’s Plants. A visit to a Metal Fab facility is a sensory experience a person never forgets. Ken Holz: Bliss Toledo double action drawing press, Oldsmobile probably had a couple dozen of these back in the day. As far as I know Oldsmobile was doing all of their own stamping up through the mid sixties, so this was probably in an Oldsmobile plant. Bodies and doors came from Fisher Body. Sonny Turismo: Ken Holz Bliss is still in business in Hastings MI. We just did all new electrical on a similar double action....been in press controls 30 years. I'm not sure where the ownership money comes it comes from but the company is now called BCN or Bliss clearing Niagara. Over the years as press companies failed Bliss obtained the rights to the designs and parts business. If so Google Bliss munitions they have a fantastic ammunition press business. Mike Austin: I've been in nearly every stamping plant mentioned over the years, was/am fortunate to be in the automotive and appliance stamping business. This Bliss is pre-JiC and is indeed a toggle double action draw press at Oldsmobile, it's in a low headroom area which they were hampered with (like Fisher Body) so it's a special press design with drive dropped into the slide area and unique toggle link to the blankholder/outer slide. Wouldn't have rolled up sleeves today... [There are several interesting comments on this post including a 40' deep concrete pad under presses.] |

This collection of photos in a Russian locomotive shop shows a variety of drop hammers and presses used in the forging shop.

(new window) The "new window" link skips the "road trip" part.

12:04 video of forging a big propeller shaft

4:03 video of various forging operations

The forge press machine is suitable for the stamping and pressure setting process of various metal parts and is widely used in automobiles, motorcycles, daily hardware, instrumentation, gas appliances, and other industries.

ReplyDeletehttps://www.guangduanpresses.com/product/detail/closed-type-single-point-forge-press-machine-jh31-series.html