|

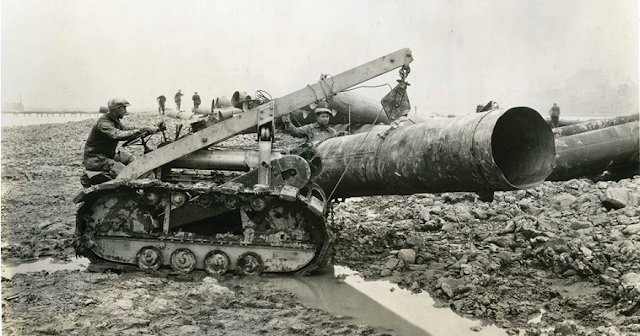

| OffHighway The ability of sidebooms and pipelayers to walk with a long strand of pipe makes possible a project like this. Bechtel Corporation is walking a 600-foot strand of pipe into the Niagara River for the Tennessee Gas Transmission Company on September 11, 1954. This was the first pipeline to cross the Niagara, and a fleet of Cat MD7s, equipped with extra counterweights, is doing the honors. The MD7 was a very popular sideboom; fleets of them still turned up in pipeline auctions into the early 2000s. |

|

It continues to amaze me how much a big steel pipe can bend.

|

| Caloto posted |

|

| pipelineprovisions, cropped |

|

| Big Machine posted |

|

| 1 of 9 photos posted by Hector Sierra Tuxpan Pipeline |

|

| Sk Ridoy Khan Jak posted Wow 😲 [Because of the plugs in the ditch, some comments are indicating this is AI.] |

|

| Pipeline cartel posted |

As expected, Pipeline cartel has a lot of photos of sidewinders in action. Here are some more.

|

| Pipeline cartel posted |

|

| Pipeline cartel posted Beauty by Dustin Richard Richard Hoare: We never used this many side booms to lower the pipe line into the trench back in the 1960s 🤔 Kenneth R Hart: Richard Hoare But it appears to be a long concrete coated section..... maybe for a road or river crossing. [In other words, the pipe won't bend, so they needed a lot of sidewinders to hold it straight.] Robert Clark: A 36” pipe with coating is heavy. One slips, the pipe is laid😃 I think it was asphalt? Because it had to be heated to bend. Before that it was tar? wrapped with paper., A machine that wrapped 3 rolls @ a time. |

.jpg) |

| Pipeline cartel posted 📸Chuck Powell Denis Ladouceur: Belle job David Lambert: Idaho 1992/3…. Jorge Lira: 48”? Brodie Clegg: Michels cgl. Was on this crew with Aaron. Zach Zorn: The legendary Chuck Powell Chuck Powell: Zach Zorn thank you, love my job, keeping the boys making the green. Won’t get to see this much big bad iron together for a few years. It’s about time I share some shots. Being the mainline mechanic has its perks.🤘🏼 Carroll Keatts: Must be some heavy duty side wall to have that many side booms Ansen Smith: I hope the bending engineer calculated the shift formula for that bend! Remi Buttinghausen: Last I knew you can't fit a big circle inside a smaller one I hope they have there geometry right and welds strong. [I was wondering about that. And the need for the end of the pipe to end up exactly at the end of the yellow pipe sticking out of the ground.] Ron Maclellan: Ansen Smith if a engineer was involved the crew would have to fix the engineers mistakes , engineers are good drivers designing something that the work crew can modify to make it work properly . Jason Laughlin: A work of art and a thing of beauty. Map props to these hands. Especially that tie in foreman !!! Richard Mann: Is it true that the line gets pressure tested for leaks after it is in the ground and covered with earth? Derek Lloyd: Richard Mann yes. It’s usually done before the earth is put back over incase any repairs are needed. They rarely have issues since every weld is x-ray’d to keep quality of the welds held to a high standard. Jeremy Kegley: Richard Mann everything is pressure tested and the welds are X-ray tested. Those are some real welders there. |

Before the invention of the sideboom.

John Doerksen posted two photos with the comment: "Henuset stringing 42” with the conventional split drum stringing setup with a double line compared to Midwest/Pioneer using the cable bridle setup with blocks on the bottom of the boom and the regular load line blocks. Slightly slower but much more lifting power."

|

| GLDD-hilstory-gallery |

|

| GLDD-hilstory-gallery |

John Doerksen posted two photos with the comment: "Henuset stringing 42” with the conventional split drum stringing setup with a double line compared to Midwest/Pioneer using the cable bridle setup with blocks on the bottom of the boom and the regular load line blocks. Slightly slower but much more lifting power."

|

| 1 |

|

| 2 |

John Doerksen posted two photos with the comment: "Henuset. Chain Lakes 36”. 1988? Pocket weight 16A583,split drum,double lined. Everybody liked that tractor. Ed Galpin did the stringing. Pioneer hauled the pipe on Henuset poles. This is still a tandem. Arthur converted them all to tridems."

|

| 1 |

|

| 2 |

Speaking of pipelines, this is probably what was used to move natural gas.

|

| Kevin Smith posted What is this? Been following for a while but this is my first post. This photo is circa 1968. 90% sure it was taken at or near Boone IA. I'm trying to confirm what is in the background and possible location this photo was taken. I believe it to be a diesel engine. Possibly a static mount for display or training purposes. Any ideas? Thx Chris Beck: My bet is an engine at a natural gas pumping station. The pumping pistons are behind the guys and are directly connected to the engine crankshaft. I used to live in southern Indiana and we had a Texas Eastern pumping station just down the road and had a tour of it. Mind you this was 45+ years ago. It’s probably electrified by now. But back then if you stood over top of the pipeline (which was somewhere between 24” and 36” diameter) several miles away from the station you could hear (and feel) the pulsations through the ground. It was pretty freaky. They would ebb and flow as the pulses from the various engines would change timing slightly. Robert Longhofer: It's a compressor. Hard to say if it's natural gas or air. If it's natural gas, it's probably natural gas fuel, spark ignited. These things last for decades, it might still be in service. [An 8-cylinder engine behind the compressor] |

|

| Jonah Hemingway posted An old SD40-2 getting put back on the rails on Golden Avenue in Springfield, MO last Tuesday. [9-3-2019] |

|

| Screenshot |

Hulcher is a contractor that has developed the sideboom as a tool for cleaning up derailments.

|

| Hulcher-derailment |

|

| Hulcher-load-out [That would be the rotor for a generator in a power plant.] |

|

| LevelLandNews [Hulcher cleaning up a derailment.] |

|

| Hultcher-sideboom |

|

| Hultcher-case-study |

|

| Byron Willcutt updated Ron Schlegel 4 side booms make short work at derailments Kraig Hausenfleck Ron Schlegel when you have 4 operators that all can work together yes but if not it’s more of a pain in the butt sometimes Ron Schlegel Kraig Hausenfleck we wore radio headsets |

|

| Terry Fisher photo |

|

| Screenshot @ -6:08 from Gil Moser post Derailment on the Van Buren Sub in Morgan Arkansas, Second set of trucks on second unit derailment and split the switch at Control Point (CP 336) to siding. Dragging half the second unit across Bridge 336.3(1) (4-Spans RCS) Hope Ya'll enjoy video. Doug Meigs Need to use an Atlas re-railer. [I'm too lazy to research an "Atlas re-railer." I think the end of the video is the same clip repeated a few times. I never did figure out what the excavator was doing. Later I saw the cable was being pulled by a tracked front-end loader instead of another locomotive.] |

|

| Harry Brannen posted, cropped [Sometimes a railroad is welling to pay for a sideboom for each corner of a car. We can see on the right-front unit that the how the counterweight moves out to balance the load.] |

|

| John W. Coke posted Donahue Brothers, Inc. Clarence Thibodeaux Side booms are best for re railing. Carl Brooks Used Hulcher’s in the Detroit area...it was amazing just watching them do their job with the sidewinders.... |

|

| John W. Coke Donahue Bros Inc Ray Jones sidewinders, the KING for derailments and other track work.......... |

|

| John W. Coke posted Donahue Brothers, Inc. [They have four sidebooms on the job, one for each corner.] |

|

| Donahue Brothers, Inc. posted |

Lisa Catera posted three photos of a derailment with the comment: "This morning [6/6/2019] in Taylor TX."

James Patterson Sidewinders

George Dubbs Yep called sidewinders four can get hold on each corner of the biggest locomotive or loaded freight car And carry it to good track and put it back on track....used them many times,time savers verses old wrecking cranes.....

|

| 1 |

|

| 2 |

|

| 3 |

|

| Wayne Helms posted |

Kevin Flynn Tom Klimczak , Hulcher can set up 2 booms in under 30 minutes.

David Koziol Ken Schmidt when I was having a talk with Glen Hulcher in Denton a few years back he told me that he was in the business of moving men and machines.

Ken Schmidt David Koziol They sure are. One morning while I was getting coffee, I saw a parade of trucks on US 65, lights flashing.

You didn't need much prompting as to what happened, all one had to do was follow the leader and find out where.

|

| 1, cropped |

|

| 2, cropped |

|

| 4 |

|

| 6 |

Tyler Glass posted two photos with the comment: "This is what happens when industry doesn’t listen to the person who inspected the track and doesn’t let them fix it."

Keith Todd You know its bad when the sidewinders show up.

Trestin Minefee Good ole side booms!

Thaine Brown What the hell are those critters?

Don Whatley Thaine Brown D9 Cat bulldozers with side booms.

There were no injuries. One report called it a sand train. But some of the hoppers are too long for sand. And at 0:08 the yellow bulk-head flat car looks like it is carrying lumber.

(new window) In addition to sidebooms, the other goto "clean up tool" is an excavator with a "thumb."

The comments on this share as well as the video below indicates this rerailer can be used for locomotives as well. It seems much cheaper and faster than swinging a locomotive from a couple of hooks. Unless UP 9714 above ended up with the wheels some distance from the tracks.

Terry Dabbs We used to do that with wood blocks. Re-rail em and get back to work. Now-a-days, you drop 1 wheel on the ground and you’ll see 5 semi’s with heavy equipment heading towards it.

Andy Peters Re-rail frogs are still used, not a image of by gone days.

Re-rail frogs are still used, not a image of by gone days.

(new window) The action starts at 1:38. Note there is one "white hat" for each sideboom operator giving the signals. At 15:04, they shutdown and move the sidebooms to the rear of the car and just pull the front truck through the dirt. They steered the front trunk by changing were they pull on it. At 23:21 you can see gravel on top of the springs of the truck. So the truck got buried pretty deep to stop the locomotive's first pull. The buried truck is why they moved the sidebooms to the back of the car and allowed the front truck to plow dirt. Would four sidebooms fit? That is, one at each corner.

(new window) Facebook no longer saves a link to the post. I remember one of the comments wondered about why did they lift it so high to replace the truck? They must have been planning to do something other than truck replacement because I think they would have left the truck on the tracks if it was being replaced. I notice that the guys on the right side had enough sense to step back as they noticed the lift was getting rather unstable. Note that the "white hat" decided to look to his left just as the two blocks on the left touched each other and broke the cable.

Update:

Tim Twitchell posted four photos with the comment: "I just like these pictures.....We changed all six traction motors on this big unit just a couple days before Christmas.... One of the guys took these....I was on a sideboom."

Don Whatley Thaine Brown D9 Cat bulldozers with side booms.

|

| 1 |

|

| 2 |

|

| Robert Learmont posted

Derailments can sometimes be fun.

Note to all before you comment - realize that there are different senses of the word “fun” and realize that derailments can occur on vastly different scales and have vastly different impacts. I’ve been railroading for a bit over half my working life, and been a stuporvisor (mechanical foreman on the loco side) for a bit over six years. That’s a very short time compared to many people here, and it is significantly longer than many who wish to critique who have never railroaded for a day in their life. I do fully realize the impacts that derailments can have on the railroad, and on the railroad’s customers, as well as any other delay or mishap. I have to keep a supply of power headed out to trains, no matter what factors affect us. I get to respond to issues and service interruptions out of my limits, which can include derailments that are in terribly inconvenient places for the operation of the railroad. A big part of how my team has to operate is based on understanding of how different unforeseen circumstances will affect the railroad and the railroad’s customers. I am also charged with the safety of a team of craftspeople, which is a duty that I do not take lightly. Even when something minor, like in the picture, happens, it is costly, someone is probably going to get sent to investigation, and it really can be a royal pain in the arse to reshuffle everything to keep the rest of the railroad flowing, and make sure the people keeping the railroad flowing are doing so safely.

Despite all that, I’ll maintain that derailments can be fun, and if you read the replies to the first comment, you will see why.

Corwith DSF (Chicago, IL), February 2016.

Robert Learmont All sorts of ways. It’s something that you don’t see every day, for one. It’s neat to watch the contractor come in with their sidebooms, set up, and do their lift. It’s quite honestly sort of fun to throw the terminal into a tizzy, when two out of the three ways in and out of your service track are blocked by something that can’t be moved, and all the outbound consists have to be reshuffled since the only way in and out is now through the opposite end than is normally used, also meaning that the terminal has to route consists the long way through the yard. It’s neat to watch the contractors working in hairy situations too, like when they do a lift on a bridge that runs over a city street. Really, it just throws a wrench into the best laid plans, and it can be entertaining to watch the resulting dumpster fire. [I recognize Robert as a railroad employee, not a railfan.] Noe Gutierrez The very first derailment I "experienced" was fun. I was a kid, in junior high, I think, and had wandered off from the store my mom worked at in downtown McAllen to go visit the SP yard four blocks away. I found a crew stranded when their GP9 had dropped a wheel off the rail while spotting (or picking up?) cars on the interchange track with the MP. As they stood around helplessly waiting for assistance to arrive from Edinburg, one of them handed me some money and asked me to go get them a drink. I hurriedly ran back to my mom's store and began grabbing Coke bottles from the machine in the back of the store. My mom asked what was going on and I excitedly told her I was helping out a train crew at a derailment before running back out with the bottles. I think I remember her saying "Well be careful!" as I ran off. The crew was glad of the Cokes and I got to stick around and watch as the engine got re-railed with the help of large blocks of wood cribbing brought in by company pickup from Edinburg. It’s neat to watch the contractors working in hairy situations too, like when they do a lift on a bridge that runs over a city street. Really, it just throws a wrench into the best laid plans, and it can be entertaining to watch the resulting dumpster fire. |

|

| Aaron Thomas posted, cropped Brendan J Dock shared carry on, nothing to see here Mark Gillings Donated to a museum without a rail connection. |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

(new window) In addition to sidebooms, the other goto "clean up tool" is an excavator with a "thumb."

The comments on this share as well as the video below indicates this rerailer can be used for locomotives as well. It seems much cheaper and faster than swinging a locomotive from a couple of hooks. Unless UP 9714 above ended up with the wheels some distance from the tracks.

Terry Dabbs We used to do that with wood blocks. Re-rail em and get back to work. Now-a-days, you drop 1 wheel on the ground and you’ll see 5 semi’s with heavy equipment heading towards it.

Andy Peters

Re-rail frogs are still used, not a image of by gone days.

Re-rail frogs are still used, not a image of by gone days. |

| Screenshot |

(new window) The action starts at 1:38. Note there is one "white hat" for each sideboom operator giving the signals. At 15:04, they shutdown and move the sidebooms to the rear of the car and just pull the front truck through the dirt. They steered the front trunk by changing were they pull on it. At 23:21 you can see gravel on top of the springs of the truck. So the truck got buried pretty deep to stop the locomotive's first pull. The buried truck is why they moved the sidebooms to the back of the car and allowed the front truck to plow dirt. Would four sidebooms fit? That is, one at each corner.

(new window) Facebook no longer saves a link to the post. I remember one of the comments wondered about why did they lift it so high to replace the truck? They must have been planning to do something other than truck replacement because I think they would have left the truck on the tracks if it was being replaced. I notice that the guys on the right side had enough sense to step back as they noticed the lift was getting rather unstable. Note that the "white hat" decided to look to his left just as the two blocks on the left touched each other and broke the cable.

Update:

|

| Screenshot @ -4:26 [A row of sidebooms tipping like dominoes. They evidently needed bigger counterweights for this job.] |

|

| One of 22 photos posted by Tim Twichell [I selected this one because it does show that the counterweights and boom are transported separately.] |

Tim Twitchell posted four photos with the comment: "I just like these pictures.....We changed all six traction motors on this big unit just a couple days before Christmas.... One of the guys took these....I was on a sideboom."

Dennis DeBruler shared

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

Tim Twichell posted three images with the comment: "Speaking of Spent Nuclear Fuel Rods....Here is a job that Winter's Rigging did....In Buffalo. Years a go now. 360,000 lbs for the car & cask. It was an Empty Spent Naval Reactor Rod unit. These trains are protected by heavily armed and armored caboose style cars. With people inside you would not want to mess with."

|

| 1 |

|

| 2 |

|

| 3 |

River Rail Photo has an album of four photos showing several sidebooms rerailing tank cars. "All of the cars rolled away on their own wheels."

More examples of CSX and other railroads keeping sidebooms busy

A YouTube video starting with failure of re-railer and then the sideboom action. What are they torching? Did they have to weld on lift brackets? The start of the lift

Mike Kaluhiokalani Jr. shared

John Sohn I was one of the guys who worked that job and I have to say great camera work.

Dylan Miles Haha i remember this! I look like a baby.

I saw several posts concerning this derailment. Here are a couple for some context: overview and details. My motivation for noting the derailment is this video. In particualr, I was surprised, starting at 0:29, how they move one end of the locomotive sideways by tipping a sideboom over.

(Update: I add this one because many of the comments are probably by railroad employees. Towards the end, this one has some drone shots. Some of those shots show how much rock they hauled in to reduce the slope of the embankment. 40 photos)

|

| Screenshot @ 0:29 |

|

| Screenshot, a rectangular grain elevator |

|

| Screenshot, another rectangular grain elevator? |

|

| Screenshot, this video has several detailed views including a sideboom tilt. The "white hat" giving signals strikes me as being too close to the dangling locomotive. |

|

| Screenshot |

%20Facebook.png) |

| Facebook Reel |

%20Facebook.png) |

| Facebook Reel |

A video of a bunch of sidewinders pulling a locomotive out of the Big Sandy River near Pikeville, KY

[I hope the people driving equipment on the landfill built along the cliff get hazard pay.]

Thanks a lot for sharing this information with us.

ReplyDeletePlease visit this for 8E5450 Seal Caterpillar Bulldozer and Track Loader

Great info

ReplyDeleteWant to find more?

please click

Dozer Rental Services, Bulldozer on Rent, Bulldozer Rental Services Provide

Great info

ReplyDeleteWant to find more?

please click

Track Shoe Bulldozer, Track Roller Bulldozer, Track Link Bulldozer