|

| MWRD posted The MWRD’s Stickney Water Reclamation Plant transforms as much as 1.2 billion gallons of water per day, serving 2.3 million people from central Chicago and 46 suburban communities. |

"The full Stickney facility is split into two plants—a western plant which entered service in 1930 and a southwest portion that opened nine years later." [gizmodo] In 1929 the Supreme Court agreed with Wisconsin that MWRD could not continue to use Lake Michigan water to flush its raw sewage down the river. So that explains why MWRD built a plant in 1930. With the reduction of raw sewage in the river, a reduced flow out of the lake would be sufficient to keep the river from smelling. [Wikipedia] To reduce the flow, MWRD built a lock at the mouth of the Chicago River.

A video using the O'Brien WTP as the example. I learned they pump the solids here for further processing.

</update>

|

| AphaPublications. p8 |

|

| Metropolitan Water Reclamation District of Greater Chicago , CC BY-NC-SA via menafn Stickney, with downtown Chicago visible in the distance top left. |

|

| MWRD posted, cropped |

On May 21, the Metropolitan Water Reclamation District (MWRD) hosted an open house of their Water Reclamation Plants. I chose Stickney because it is the closest and largest. In fact, they still claim to be the largest in the world. (As the host explained, "largest" is like the tallest skyscraper, ---you get a different answer depending on what you choose to measure. I know that is the case with steam locomotives as well. UP's Big Boy is generally considered the largest. But if you consider horsepower to be the most important metric, then Pennsy's Q2 at 7,900hp is the largest. The host did not elaborate on what metric they use when they claim "largest." Their brochure says "one of the largest.")

This is the garden they had us wait in until the next tour could start. I learned later that it is one of their roof gardens. The district does practice the water conservation efforts that they are trying to encourage others to do such parking lot pavers and native prairie restoration. They also advocate rain barrels and surge ponds to put storm water into the ground rather than into the sewers.

They then had us move to a conference room to play a video and have questions and answers afterwards. Fortunately, I noticed that the video has been posted on line. But then it was removed. But I found the following update.

(new window)

During Q&A, I pointed out that the video did not mention that they now disinfect the effluent of some of their plants (Calumet and O'Brien). I learned that there are no plans to add disinfection to Stickney. Unlike the North Channel and Cal-Sag, no recreational use (e.g. kayaking) is envisioned for the shipping canal into which it dumps water. Plus I learned that the bacteria dies within two miles of the plant's outlet anyhow.

A typical treatment plant in Illinois handles one million gallons per day. This plant can process 1,440 million gallons per day (mgpd). That is, it can process in a minute what a typical plant does in a day. I remember the host saying that during a normal day they process 250 mgpd. But their brochure says 700 mgpd. The spare capacity is important in order to be able to handle storm water since Chicago has combined sewers. That spare capacity will be used extensively to treat the water caught in a reservoir once the TARP project is done. (TARP is a subject that is still on the todo list. Fortunately, MWRD has a web page about it.)

We then moved on to the control room where the host spent the entire time using this graphic on the wall to explain how the water is treated. I'll crop out details as part of the bus tour below.

One side of the area we were in was windows into the control room.

Along the opposite wall was some pictures of historical views and some artifacts.

Obviously, the panel on the right is one of the panels they used before computers became available.

This control stand is from an engine of their own railroad for hauling biosolids when the controls for the engine were upgraded.

This control stand is from an engine of their own railroad for hauling biosolids when the controls for the engine were upgraded.

As we left to get on a bus for a tour of the plant, I grabbed photos of the historical views they had on the wall. I added their text as the caption. (You can click on a picture to get a bigger version.)

The tour bus route took us in a direction that was opposite of the water flow through the plant. I'm going to discuss the photos in the order that the water flows. The first phase of treatment is passing through vertical steel bars spaced one inch apart. This protects the pumps from objects that would damage the pump's impeller blades. Periodically they rake off the collected trash. Of the odd objects they have seen, the one I remember is a bowling ball.

The pumps are in the pump and blower house. Fortunately, I took a lot of pictures because the only decent shot I have of the house is in the background of another shot. The pumps push the water up 55 feet from the course screens terminating the interceptor sewer to the Aerated Grit Tanks. Each pump has a 3,600hp motor. This is the only time the water is pumped. From there gravity is used to flow from one tank to another until it finally discharges into the canal.

I'll let the graphic explain the Aerated Grit Tanks (preliminary treatment). (Remember, you can click the picture to get a larger version.)

This is the area of the Aerated Grit Tanks.

A side view of a tank. You can see lots of bubbles leaving the water. The blowers that are in the above pictured pump and blower house each have a 10,000hp motor using 13kv. They have to contact ComEd before they turn one on because it will run at 60-80,000hp for 15-20 seconds as it spins up the blower. "It does dim the lights."

A side view that shows the tops of the conveyors. By this time I learned to stand up when I had to take pictures of something on the opposite side of the bus so that there were not heads at the bottom of the picture.

Then the water flows to the Primary Settling Tanks (primary treatment).

You can see the paddles that skim the surface.

In these tanks that have been drained for maintenance, you can also see the paddles along the bottom.

Activated Sludge Aeration Tanks (secondary treatment). I believe the "activated" is the bacteria they grow in the tanks. The amount of air they need to pump in depends on the amount of bacteria that are growing. The bacteria eat a lot of the "solid human waste." The host mentioned that they were having trouble with one of their other plants because someone was dumping cyanide down the drain and that was killing their bacteria. They know when the bacteria goes down because the oxygen levels go up since no bacteria are consuming it. They did a lot of work trying to find the culprit. They finally found the source of the cyanide when the culprit divorced his wife and the wife tattled on him. The host pointed out that if you are doing something very criminal and your wife knows about it, you should probably not divorce her. Another story he told is when someone accidentally dumped a lot of vinegar down the drain. They were notified when the accident happened so they knew an issue was on its way to the plant. But they did not know what the impact would be. It turned out the oxygen levels went way down because the bacteria loved it and thrived. The host emphasized that since the 1930s, the plant does not using any chemicals, just biological processes. If you note the dates on the above construction pictures, they are in the 1930s.

(Update: I assume these are some of the the aeration tanks. Look at how the air makes the water churn.)

I could not get a side view of these tanks because they are surrounded on both sides by the next stage of treatment.

Final Settling Tanks (terterary treatment).

This is one of the 96 final settling tanks. You can see the trough in the middle into where the clean water flows to leave the plant. The duck on the water must agree that the water on top is clean.

Battery C was out-of-service for maintenance. That is one-fourth of their capacity. I wonder if they will have it back in service before the next round of rains hit the area.

The solids that settled out of water treatment tanks first go to Concentration Tanks. I don't remember seeing them on the bus tour. They may have been enclosed to control odor. BTW, I did not smell anything doing the entire tour. Later, when I was driving around the area, I did smell odors from the chemical plant to the east.

The solids then go to a centrifuge to remove the water. For a picture of the centrifuge plant, see the railroad post. The extracted wastewater goes to the activated sludge aeration tanks for more treatment.

The biosolids then move to Anaerobic Digesters. Here bacteria eat the biosolids and excrete natural gas. As the video explains, they have expanded their capacity so that they can accept organic waste from other sources such as food processing plants so that they can create more gas to help them achieve their energy neutral goals.

The digesters are up on a hill, but they did not explain why they were up on a hill. The biosolids then go from the digesters to second set of centrifuges and then are dumped into the railroad cars to be dried in the field. They also have installed equipment that uses heat to dry the biosolids and forms them into pellets.

I marked the satellite image below with the following convention:

Update:

|

| 20160521 3184 |

They then had us move to a conference room to play a video and have questions and answers afterwards. Fortunately, I noticed that the video has been posted on line. But then it was removed. But I found the following update.

(new window)

During Q&A, I pointed out that the video did not mention that they now disinfect the effluent of some of their plants (Calumet and O'Brien). I learned that there are no plans to add disinfection to Stickney. Unlike the North Channel and Cal-Sag, no recreational use (e.g. kayaking) is envisioned for the shipping canal into which it dumps water. Plus I learned that the bacteria dies within two miles of the plant's outlet anyhow.

A typical treatment plant in Illinois handles one million gallons per day. This plant can process 1,440 million gallons per day (mgpd). That is, it can process in a minute what a typical plant does in a day. I remember the host saying that during a normal day they process 250 mgpd. But their brochure says 700 mgpd. The spare capacity is important in order to be able to handle storm water since Chicago has combined sewers. That spare capacity will be used extensively to treat the water caught in a reservoir once the TARP project is done. (TARP is a subject that is still on the todo list. Fortunately, MWRD has a web page about it.)

We then moved on to the control room where the host spent the entire time using this graphic on the wall to explain how the water is treated. I'll crop out details as part of the bus tour below.

|

| On the wall of the control room observation area of the Stickney plant |

|

| Excerpt from wall graphic |

Along the opposite wall was some pictures of historical views and some artifacts.

Obviously, the panel on the right is one of the panels they used before computers became available.

This control stand is from an engine of their own railroad for hauling biosolids when the controls for the engine were upgraded.

This control stand is from an engine of their own railroad for hauling biosolids when the controls for the engine were upgraded.As we left to get on a bus for a tour of the plant, I grabbed photos of the historical views they had on the wall. I added their text as the caption. (You can click on a picture to get a bigger version.)

|

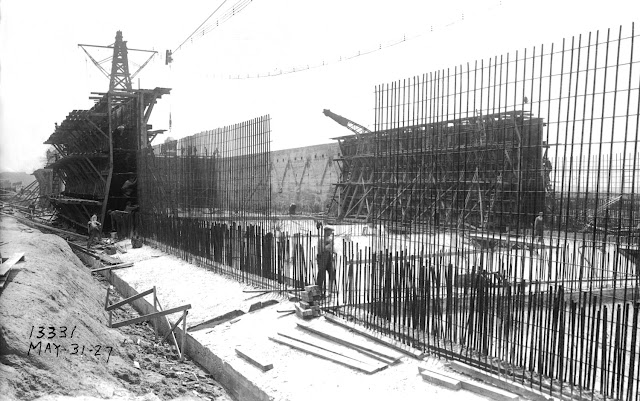

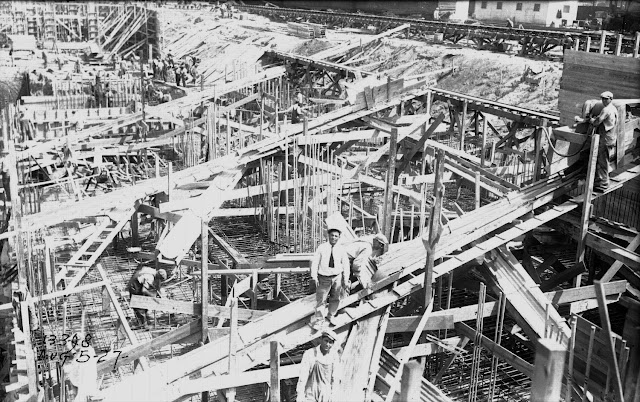

| West Side Sewage Treatment Works (ca. 1928) Construction of the West Side Sewage Treatment Works Bottom: Pump Discharge Conduits Middle Left: Skimming Tanks Top Right: Imhoff Tanks |

|

| Southwest Sewage Treatment Works (1938) Installation of 98 Rotary Vacuum Filters in the Sludge Disposal Building Demolished (2010) |

|

| Southwest Sewage Treatment Works (1937) Installing the lower half of a Main Sewage Pump Volute. The volute is inverted in this picture (suction is on top and discharge is to the right) |

|

| Southwest Sewage Treatment Works (1935) Construction of Battery A Final Tanks In the distance are Aeration Tanks of batteries A&B |

|

| Excerpt from wall graphic |

|

| Pump and Blower House |

|

| Excerpt from wall graphic |

This is the area of the Aerated Grit Tanks.

A side view of a tank. You can see lots of bubbles leaving the water. The blowers that are in the above pictured pump and blower house each have a 10,000hp motor using 13kv. They have to contact ComEd before they turn one on because it will run at 60-80,000hp for 15-20 seconds as it spins up the blower. "It does dim the lights."

A side view that shows the tops of the conveyors. By this time I learned to stand up when I had to take pictures of something on the opposite side of the bus so that there were not heads at the bottom of the picture.

Then the water flows to the Primary Settling Tanks (primary treatment).

You can see the paddles that skim the surface.

In these tanks that have been drained for maintenance, you can also see the paddles along the bottom.

Activated Sludge Aeration Tanks (secondary treatment). I believe the "activated" is the bacteria they grow in the tanks. The amount of air they need to pump in depends on the amount of bacteria that are growing. The bacteria eat a lot of the "solid human waste." The host mentioned that they were having trouble with one of their other plants because someone was dumping cyanide down the drain and that was killing their bacteria. They know when the bacteria goes down because the oxygen levels go up since no bacteria are consuming it. They did a lot of work trying to find the culprit. They finally found the source of the cyanide when the culprit divorced his wife and the wife tattled on him. The host pointed out that if you are doing something very criminal and your wife knows about it, you should probably not divorce her. Another story he told is when someone accidentally dumped a lot of vinegar down the drain. They were notified when the accident happened so they knew an issue was on its way to the plant. But they did not know what the impact would be. It turned out the oxygen levels went way down because the bacteria loved it and thrived. The host emphasized that since the 1930s, the plant does not using any chemicals, just biological processes. If you note the dates on the above construction pictures, they are in the 1930s.

(Update: I assume these are some of the the aeration tanks. Look at how the air makes the water churn.)

|

| MWRD |

I could not get a side view of these tanks because they are surrounded on both sides by the next stage of treatment.

Final Settling Tanks (terterary treatment).

This is one of the 96 final settling tanks. You can see the trough in the middle into where the clean water flows to leave the plant. The duck on the water must agree that the water on top is clean.

Battery C was out-of-service for maintenance. That is one-fourth of their capacity. I wonder if they will have it back in service before the next round of rains hit the area.

The solids that settled out of water treatment tanks first go to Concentration Tanks. I don't remember seeing them on the bus tour. They may have been enclosed to control odor. BTW, I did not smell anything doing the entire tour. Later, when I was driving around the area, I did smell odors from the chemical plant to the east.

The solids then go to a centrifuge to remove the water. For a picture of the centrifuge plant, see the railroad post. The extracted wastewater goes to the activated sludge aeration tanks for more treatment.

The biosolids then move to Anaerobic Digesters. Here bacteria eat the biosolids and excrete natural gas. As the video explains, they have expanded their capacity so that they can accept organic waste from other sources such as food processing plants so that they can create more gas to help them achieve their energy neutral goals.

The digesters are up on a hill, but they did not explain why they were up on a hill. The biosolids then go from the digesters to second set of centrifuges and then are dumped into the railroad cars to be dried in the field. They also have installed equipment that uses heat to dry the biosolids and forms them into pellets.

|

| Excerpt from wall graphic |

- red: Offices and parking

- green: Final Settling Tanks

- yellow: Activated Sludge Aeration Tanks

- dark blue: Primary Settling Tanks

- light blue: Aerated Grit Tanks

- orange: Pump and Blower House

- purple: Anaerobic Digesters

- brown: Centrifuge House

- black: Phosphorous Recovery

|

| Satellite |

|

| MWRD posted Oct 8, 2021 March 9, 1927 MWRD posted Construction of the West Side Sewage Treatment Works, one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant, on March 9, 1927. |

|

| MWRD posted Dec 4, 2021 March 9, 1927 MWRD posted Construction of the Stickney Water Reclamation Plant (WRP) on March 9, 1927. MWRD posted |

|

| MWRD posted on Jan 18, 2022 Construction of the Stickney Water Reclamation Plant (WRP) on April 20, 1927. MWRD posted |

|

| MWRD posted Construction at West Side Sewage Treatment Works on January 11, 1928, viewed to the west from the pumping station. MWRD posted |

MWRD posted three photos with the comment: "Three "elevated" views of early construction and excavation at the West Side Sewage Treatment Works on May 7, 1927. The West Side Plant was placed in service in 1930 and the adjoining Southwest Plant was placed in service in 1939. The two facilities were eventually combined and renamed the Stickney Water Reclamation Plant, now one of the largest wastewater treatment plants in the world."

|

| 1 |

|

| 2 |

|

| 3 |

The pumping station has to be deep because the bottom has to be below the sewers. And the sewers have to be low to provide the gradient needed for sewage to flow to the pumphouse.

|

| MWRD posted Excavation for the pumping station at the West Side Sewage Treatment Works on May 7, 1927. |

|

| MWRD posted Construction of Imhoff tanks at the MWRD's West Side Sewage Treatment Works, now part of the Stickney Water Reclamation Plant (WRP), on May 7, 1927. Imhoff tanks were an important part of early wastewater treatment operations but have been replaced by more efficient processes and facilities. |

|

| MWRD posted A view to the northwest showing construction of settling tank walls for the West Side Sewage Treatment Works on May 7, 1927. |

|

| MWRD posted Excavation for preliminary settling tanks at the MWRD's West Side Sewage Treatment Works, now part of the Stickney Water Reclamation Plant (WRP), on May 31, 1927. |

|

| MWRD posted Construction of the Stickney Water Reclamation Plant (WRP) on May 31, 1927. MWRD posted |

|

| MWRD posted on Sep 10, 2022 Construction of the foundation for the pumping station at the West Side Sewage Treatment Works on June 24, 1927. |

|

| MWRD posted A view to the northwest from the top of an on-site concrete plant showing Imhoff tank facility construction for the West Side Sewage Treatment Works on June 24, 1927. Imhoff tanks were an important part of early wastewater treatment operations but have been replaced by more efficient processes and facilities. |

|

| MWRD Construction of the West Side Sewage Treatment Works on August 5, 1927. MWRD posted Construction of the West Side Sewage Treatment Works on August 5, 1927. MWRD posted again |

|

| MWRD posted on Dec 10, 2021 Construction of the pump house foundation at the Stickney Water Reclamation Plant (WRP) on August 5, 1927. |

|

| MWRD posted A view of Imhoff tank construction at the West Side Sewage Treatment Works on August 5, 1927. |

|

| MWRD posted Construction of a grit chamber tank at the Stickney Water Reclamation Plant (originally called West Side Sewage Treatment Works) on October 19, 1927. MWRD posted MWRD posted |

|

| MWRD posted on Mar 19, 2022 Construction of tanks at the West Side Sewage Treatment Works on December 29, 1927. |

|

| MWRD posted Construction at West Side Sewage Treatment Works, one of two plants that was eventually renamed the Stickney Water Reclamation Plant, on December 29, 1927. |

|

| MWRD posted Construction of the masonry exterior wall for the pumping station at West Side Sewage Treatment Works, looking northwest, on December 29, 1927. |

|

| MWRD posted Construction of grit chambers at the Stickney Water Reclamation Plant on December 29, 1927. |

|

| MWRD posted Work on the intercepting sewer at approximately 3500 S. Pulaski Rd. in Chicago on April 11, 1928. |

|

| MWRD posted |

| ||

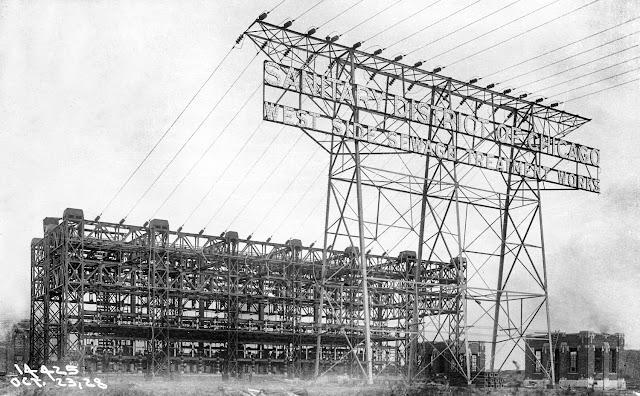

| MWRD posted A view of the West Side Sewage Treatment Works, one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant, looking north from the Chicago Sanitary and Ship Canal. A transmission line tower & substation are shown during construction on Oct 23, 1928. MWRD posted

|

|

| MWRD posted on Jun 8, 2023 Construction of Imhoff tanks at West Side Sewage Treatment Works on June 24, 1927. |

|

| MWRD posted Break time during construction at the West Side Sewage Treatment Works on July 29, 1927. |

|

| MWRD posted Workers build wall panels for Imhoff tanks during construction of the West Side Sewage Treatment Works, one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant, viewed to the southwest on August 5, 1927. MWRD posted |

|

| MWRD posted A view to the northwest from the top of an on-site concrete plant showing Imhoff tank facility construction for the West Side Sewage Treatment Works on June 24, 1927. Imhoff tanks were an important part of early wastewater treatment operations but have been replaced by more efficient processes and facilities. West Side was one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant in Cicero, IL. MWRD posted A view from the top of an on-site concrete plant showing Imhoff tank facility construction for the West Side Sewage Treatment Works on June 24, 1927. Imhoff tanks were an important part of early wastewater treatment operations but have been replaced by more efficient processes and facilities. West Side was the first of two treatment plants built, the other being Southwest Sewage Treatment Works, which were combined and eventually became the Stickney Water Reclamation Plant. Learn more about our water reclamation plants here: https://mwrd.org/water-reclamation-plants |

|

| MWRD posted Imhoff tanks, May 7, 1927 |

|

| MWRD posted on Nov 23, 2021 Excavation for the pumping station at the West Side Sewage Treatment Works on May 7, 1927. |

|

| MWRD posted Construction of interior compartment walls for Imhoff tanks at the West Side Sewage Treatment Works on June 24, 1927. MWRD posted with the same comment |

|

| MWRD posted on Apr 19, 2022 A view of the foundations for Imhoff tanks in Cicero, Illinois, on May 23, 1928, during construction of the West Side Sewage Treatment Works. |

|

| MWRD posted on May 28, 2022 An interior view of an onsite workshop during the construction of the West Side Sewage Treatment Works facility on May 23, 1928. |

|

| MWRD posted |

|

| MWRD posted Imhoff tank construction at West Side Sewage Treatment Works on July 16, 1928. |

|

| MWRD posted Construction of the Stickney Water Reclamation Plant (WRP) on July 16, 1928. |

|

| MWRD posted 📷 Construction of West Side Sewage Treatment Works, one of two treatment plants that were combined and eventually became the Stickney Water Reclamation Plant (WRP), on July 16, 1928. |

|

| MWRD posted on Nov 9, 2022 A view of an electrical vault and conduit on July 27, 1928, during construction of the West Side Sewage Treatment Works. |

|

| MWRD posted Construction and assembly of an electrical substation at the West Side Sewage Treatment Works on August 15, 1928. |

|

| MWRD posted Construction of the West Side Sewage Treatment Works on August 15, 1928, with a concrete mixer plant and pumping station in the background. |

|

| MWRD posted Construction of the West Side Sewage Works on August 15, 1928. |

|

| MWRD posted on Mar 1, 2022 Construction of the pump house for the West Side Sewage Works in Cicero, Illinois, on August 15, 1928. MWRD posted again |

|

| MWRD posted on Apr 4, 2022 Construction and assembly of an electrical substation at the West Side Sewage Treatment Works on August 15, 1928. |

|

| MWRD posted Construction of an electrical substation at the West Side Sewage Treatment Works, one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant, looking northeast from the Chicago Sanitary and Ship Canal, on October 23, 1928. |

|

| MWRD posted Construction of skimming tanks at the Stickney Water Reclamation Plant (WRP) on October 23, 1928. |

|

| MWRD posted An interior view of an onsite workshop during the construction of the West Side Sewage Treatment Works facility on May 23, 1928. The West Side plant was placed in service in 1930 and the adjoining Southwest Plant was placed in service in 1939. The two MWRD facilities are now combined and named the Stickney Water Reclamation Plant. |

|

| MWRD posted Construction of the Stickney Water Reclamation Plant (WRP) on December 11, 1935. The Stickney WRP consists of two facilities; the original West Side Plant which was placed in service in 1930 and the Southwest Plant which was placed in service in 1939. The Stickney WRP currently serves over 2.3 million people and cleans an average of 700 million gallons of wastewater per day and has the capacity to treat 1.4 billion gallons per day. Rich Sustich For the mathematically challenged, that's just under a million gallons a minute. There's a reason there are Warning and No Mooring signs posted all around the outfall. [Or 2,200 cfs] |

|

| One of six photos posted by MWRD

The MWRD Board of Commissioners, staff and contractors, including IHC Construction Companies, FH Paschen, S.N. Nielsen Joint Venture and Greeley and Hansen, joined neighboring communities and stakeholders to celebrate the completion of the $224.8-million upgrade at Stickney Water Reclamation Plant (SWRP). The nearly four-year project will improve operations and reduce odor issues associated with the wastewater treatment process at SWRP, where up to 1.44 billion gallons of water are treated per day for 2.3 million people living across 260 square miles of Cook County, including downtown Chicago and 46 other municipalities.

The MWRD constructed nine 160-foot diameter primary settling tanks and six 132-foot long aerated grit tanks, associated support facilities, service tunnels and conduits. The new infrastructure will replace labor-intensive tanks and increase digester gas production to reduce energy costs. The new tanks will also increase and improve grit removal, protect downstream piping and equipment, reduce sidestream water recycling and capture odors to benefit surrounding neighbors.

“These new tanks and facilities represent a major milestone in our evolution of water reclamation over a century of innovation at the Metropolitan Water Reclamation District of Greater Chicago,” said MWRD President Mariyana Spyropoulos. “We are replacing 90 year old Imhoff tanks with current technology to treat water during the primary phase of treatment, and as a result, it will lead to major savings for our taxpayers and the environment. We commend our staff and contractors who worked diligently to complete this project on time and on budget, working through system shut downs while keeping daily plant operations running smoothly.”

The primary settling tanks replace 108 Imhoff tanks that had been in service since 1928. While productive over a significant lifespan, the Imhoff tanks were aging and required replacement. The new tanks will allow the MWRD to increase digester gas production, reducing both energy costs for the MWRD and greenhouse gas emissions.

“This is a major accomplishment for our engineers who designed a major overhaul of our primary and grit tanks and other support facilities,” said MWRD Vice President Barbara McGowan. “The project highlights the importance of critical infrastructure investments.”

The new primary tanks will have effluent weirs and troughs covered for odor control and tunnel access pump stations containing new pumps, airlifts, an electrical substation, odor control vessels and fans and other equipment. The aerated grit facility, which will be covered for odor control, will also include shaftless screw conveyors, centrifugal and airlift pumps for improved grit removal, grit classifiers and a dumpster-loading system to weed out whatever unwanted materials flow to SWRP. Process air for the grit tanks and primary tanks will be provided by new turbo blowers.

“To operate one of the world’s largest wastewater treatment plants, we have to constantly maintain it and improve our systems,” said MWRD Commissioner Frank Avila. “These upgrades speak to our mission in sustainability and as responsive members of the community trying to fulfill our role as a good neighbor working around the clock for the betterment of the community.”

Part of the project was funded through Clean Water State Revolving Funds. The State Revolving Funds program, administered by the Illinois Environmental Protection Agency, also received financial support through the U.S. EPA to provide communities the resources necessary to build, maintain and improve the infrastructure that protects water resources.

[A video of the ribbon cutting. Evidently they started filling a tank after the ribbon was cut.] |

|

| MWRD Cover Photo |

|

| MWRD posted There may be an alligator living in the Humboldt Park lagoon, but we had a deer visit our Stickney plant this morning. Animal control escorted our guest as it walked back to the nearby woods unharmed. #GATORWATCH2K19 |

|

| MWRD posted Oh deer! Our friend has returned to the Stickney plant and this time, she's brought one of her young ones! We think she is trying to take the limelight away from #GATORWATCH2K19 [The Humbolt Park gator has eluded capture for at least four days.] |

|

| MWRD posted onstruction of the pumping station for the West Side Sewage Treatment Works, one of two treatment plants which were combined to eventually become the Stickney Water Reclamation Plant, viewed to the southeast on August 24, 1927. Lawrence Paul The spoil piles in the distance are likely left over from the canal construction. MWRD posted Construction of the pumping station for the West Side Sewage Treatment Works, one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant, viewed to the southeast on August 24, 1927. Learn more about our seven water reclamation plants here: https://mwrd.org/water-reclamation-plants MWRD posted |

|

| MWRD posted Here we are staging materials and equipment in an aerated grit tank at the Stickney Water Reclamation Plant |

|

| MWRD posted on Oct 22, 2022 An interior view an area in the pump house during construction of the West Side Sewage Treatment Works facility in Cicero, Illinois, on March 28, 1929. MWRD posted, same comment |

|

| MWRD posted Historical Photo of the Day: Twin sewer pipes under rock in an excavated tunnel in an unknown location on November 7, 1929. Toni Donahue 9 days after the stock market crashed. This is a hard job but they are probably happy to be working. Dennis DeBruler I assume that the sewer pipes get bigger as they get closer to a Water Reclamation Plant. How big are the pipes when they enter Stickney? Metropolitan Water Reclamation District of Greater Chicago Good question Dennis DeBruler. There are different sewers coming into the Stickney plant; our engineers report that Salt Creek interceptor is 7’, Argo sewer is 10’, west side #1 is 17’ and southwest #1 are two double barrel 16’. |

|

| MWRD posted July 8, 2021 Construction of the pumping station for the West Side Sewage Treatment Works on November 25, 1927. MWRD posted |

|

| MWRD posted Construction of grit chambers and skimming tanks at West Side Sewage Treatment Works on November 25, 1927. The West Side plant was placed into service in 1930 and the adjoining Southwest Plant was placed in service in 1939. The two MWRD facilities, now combined and named the Stickney Water Reclamation Plant, currently serve over 2.3 million people and clean an average of 700 million gallons of wastewater per day with the capacity to treat 1.4 billion gallons per day. |

|

| MWRD posted Construction of the pumping station at West Side Sewage Treatment Works on November 25, 1927. |

|

| MWRD posted on Jul 5, 2023 Construction of the West Side Sewage Works on August 15, 1928. MWRD posted |

|

| MWRD posted on Mar 14, 2022 |

|

| MWRD posted on Nov 1, 2021 Imhoff tank construction at the Stickney Water Reclamation Plant (WRP) on August 4, 1931. MWRD posted a cropped version of this photo |

|

| MWRD posted Construction of skimming tanks, grit chamber and coarse screens for the West Side Sewage Treatment Works on October 19, 1927. MWRD posted |

|

| MWRD posted An interior view of an onsite workshop during the construction of the West Side Sewage Treatment Works facility on May 23, 1928. |

|

| MWRD posted Construction of Imhoff tanks for the West Side Sewage Treatment Works on June 13, 1928. |

This is the same as the above but cropped differently.

|

| MWRD posted Construction of Imhoff tanks for the West Side Sewage Treatment Works on June 13, 1928. |

|

| MWRD posted Construction of the West Side Sewage Treatment Works, one of two treatment plants that were combined and eventually became the Stickney Water Reclamation Plant (WRP), on June 13, 1928. |

|

| MWRD posted on June 15, 2022 Pouring concrete for the floor of a tank on June 13, 1928, during construction of West Side Sewage Treatment Works. |

|

| MWRD posted Conduit construction at the West Side Sewage Treatment Works, now known as the Stickney Water Reclamation Plant (WRP), on September 5, 1928. |

|

| MWRD posted The Sanitary District of Chicago's (now MWRD) West Side Sewage Treatment Works, one of two treatment plants which were combined and eventually became the Stickney Water Reclamation Plant, looking north from the Chicago Sanitary and Ship Canal, showing a transmission line tower and substation during construction on October 23, 1928 |

|

| MWRD posted on Oct 2, 2022 Construction of an underground conduit for the West Side Sewage Treatment Works on October 23, 1928. |

|

| MWRD posted Construction of an electrical substation at the West Side Sewage Treatment Works looking northeast from the Chicago Sanitary and Ship Canal on October 23, 1928 |

|

| MWRD posted on Jun 6, 2022 Stickney Water Reclamation Plant on September 3, 1936. |

|

| safe_image for We now treat half the world's wastewater and we can make inroads into the other half |

MWRD posted four photos with the comment:

For immediate releaseJanuary 19, 2023Pilot algae reactor at MWRD Stickney plant to test carbon offset, and nutrient recoveryTucked in the shadows of vast treatment facilities at the Metropolitan Water Reclamation District of Greater Chicago’s (MWRD’s) Stickney Water Reclamation Plant is an unassuming greenhouse that is holding the key to sustainable wastewater treatment operations. It might look like a pop-up business, but it has long-lasting staying power and value.Inside this greenhouse, MWRD staff and their research partner, Gross-Wen Technologies (GWT), have developed an experimental pilot algae reactor. Here MWRD and GWT are growing algae from wastewater to offset carbon emissions, while also recovering nutrients that can better protect downstream water quality.It is the second time the MWRD and GWT have installed the technology that demonstrates how the MWRD can use algae to naturally uptake phosphorus and nitrogen from wastewater to support its growth through photosynthesis, utilizing the sun as its energy source. Following a successful research trial at its O’Brien Water Reclamation Plant in Skokie, this time around at Stickney, the MWRD is studying if it can successfully reduce its carbon footprint and meet its long-term goals of becoming carbon neutral.Thanks to $100,000 in new grant funding from Imagine H2O’s Fourth Annual Urban Water Challenge, GWT constructed the new revolving algal biofilm (RAB) system and greenhouse to analyze how the system can more efficiently recover nitrogen and phosphorus without the use of inorganic chemicals or energy-consuming aeration, which is the traditional method of nutrient removal.“The pilot algae reactor makes both economic and environmental sense for our taxpayers and our planet,” said MWRD President Kari K. Steele. “Testing experimental technologies to find ways to remove more ammonia using less energy in aeration tanks, while recovering both phosphorus and nitrogen, we are providing numerous benefits that include not only environmental benefits but furthering the science in this important and often overlooked area.”How it worksAfter solids are removed from the main treatment process, they are digested then dewatered through centrifuges. The extracted water, known as centrate, is conveyed to a nutrient recovery facility at Stickney where phosphorus is collected and converted into a slow-release fertilizer. The remaining water then flows to the greenhouse where it is cycled through the RAB’s vertical conveyor belts. As wastewater is passed through the RAB, the algae grow on the belts by “eating” the nitrogen and phosphorus from the water. The algal biomass grows even more rapidly by taking carbon dioxide from the atmosphere. While the nutrient recovery facility can recover most of the phosphorus, the algae reactor can recover nitrogen and the remaining phosphorus. Centrate is usually returned to the head of the treatment process and can contain up to 15 percent of the WRP’s ammonia loading.ProductThe algae are mechanically scraped from the belts and can then be utilized as a raw material in the manufacture of a variety of products, such as algae pellets as a slow-release fertilizer, sustainable aviation fuel and bioplastics. Each of these products will reduce a reliance on petroleum. Furthermore, the algae can also be composted with biosolids and land-applied as a soil amendment, digested to produce biogas, or processed as aquaculture feed — all of which return the phosphorus to the nutrient cycle. With the right amount of sunlight, nutrients, water and carbon dioxide, the MWRD can harvest more algae.Why it mattersAmmonia (a form of nitrogen) presents a challenge for water reclamation plants. It can originate from human waste or cleaning chemicals, and it is the MWRD’s job to collect it in wastewater and convert it into nitrate through nitrification followed by denitrification, where the nitrate is reduced to nitrogen gas that is released into the atmosphere. The algae system in comparison assimilates (eats) ammonia and bypasses the nitrification/denitrification process. By removing ammonia via assimilation, the algae system can further reduce carbon emissions by limiting the nitrous oxide emissions which are generated during the conventional ammonia removal process. Nitrous oxide from treatment processes and treated water resulted in approximately one-third of the MWRD’s 2021 carbon emissions.If the pilot proves to be successful and can be scaled to the MWRD size, the MWRD can use the RAB system to reduce ammonia more efficiently by using less energy at blowers to pump oxygen. Not only will the MWRD not require as much electricity for its blowers, but it can also potentially reduce chemical costs.“Our RAB, algae-based treatment process will allow the MWRD to continue its efforts in protecting water quality while also making a positive environmental impact by reducing carbon emissions” said GWT’s President Dr. Martin Gross.The MWRD will need to reduce its carbon footprint through different carbon offsets to meet higher standards set in the MWRD’s 2021-2025 Strategic Plan. The MWRD is striving to reduce its greenhouse gas emissions by 28 percent by 2025 compared to 2005 baseline levels and has embarked on a milestone of 80 percent reduction by 2050, with additional stretch targets of 50 percent reduction by 2025 and achieving net-zero by 2050. These targets are aligned with the federal government’s April 2021 announced economy-wide target of 50-52 percent reduction in greenhouse gas emissions by 2030 and a net-zero emission economy by 2050.If the pilot study proves effective and scalable, the MWRD will consider expanding the RAB to treat more water on a larger scale following technical and economic analysis. By treating 2 million gallons of water per day, the MWRD believes it can reduce its carbon emissions by up to 5,000 metric tons of carbon dioxide equivalents per year.“We thank Imagine H2O, our staff and our partners at Gross-Wen Technologies for selecting our Stickney Water Reclamation Plant to implement this groundbreaking research,” said MWRD Vice President Kimberly Du Buclet. “If successful, the pilot algae reactor can lead to innovation that will reduce energy use, lower carbon footprints and improve resource recovery of valuable nutrients that we can reuse to build a more sustainable environment.”The RAB technology was developed by GWT’s founders while performing research at Iowa State University. The system was initially developed to produce biofuels but was later adapted for treatment of municipal wastewater. The current pilot system can recover approximately 1.5 pounds per day of dry algae biomass which results in the capture of about 3 pounds of carbon dioxide per day.The Imagine H2O support is another chapter of acclaim in the RAB’s development. In 2020, the U.S. Department of Energy’s (DOE’s) Office of Technology Transitions (OTT) selected the MWRD and GWT to receive grant funding to continue developing the sustainable nutrient recovery system. Also in 2020, the international Water Environment Federation (WEF) bestowed the MWRD and GWT with the Ralph Fuhrman Medal for Outstanding Water Quality Academic-Practice Collaboration for advancing algae technology and research.A revolving algal biofilm system naturally uptakes phosphorus and nitrogen from wastewater streams to support the growth of algae through photosynthesis and energy from the sun. The MWRD is using this process to remove nutrients from the waste stream without the use of inorganic chemicals or energy-consuming aeration, which is the traditional means of nutrient removal.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Insider Tech posted 9:56 video The Stickney Water Reclamation Point in Illinois is one of the largest wastewater-treatment facilities in the world, serving about 2.3 million people and cleaning an average of 700 million gallons of wastewater a day. During rainfall, the facility can handle a whopping 1.44 billion gallons of wastewater in a single day — that's a million gallons every minute. The clean water is released into the Chicago Sanitary and Ship Canal, and the sludge that is removed from the water is converted to biosolids, which are a sustainable alternative to chemical fertilizers. For more, visit: https://mwrd.org/what-we-do |

An MWRD posting about the emissions reductions caused by the new equipment.

MWRD has posted an updated video. The MRWD also posted that they are a partner in reducing nitrogen runoff from a farm near Argenta, IL.

MWRD's page for Stickney.

MWRD posted a link to an article about the plant with the comment:

Learn about our Stickney Water Reclamation Plant, the world's largest, in this month's US Water Alliance newsletter. The Stickney WRP serves 2.3 million people in a 260-square-mile area, including the central part of Chicago and 46 suburban communities. The Stickney WRP cleans 700 million gallons of water per day, with the capacity to treat up to 1.44 billion gallons per day.

What The MWRD Has Learned About Wastewater Treatment

A video tour of Stickney

MWRD has posted an updated video. The MRWD also posted that they are a partner in reducing nitrogen runoff from a farm near Argenta, IL.

MWRD's page for Stickney.

MWRD posted a link to an article about the plant with the comment:

Learn about our Stickney Water Reclamation Plant, the world's largest, in this month's US Water Alliance newsletter. The Stickney WRP serves 2.3 million people in a 260-square-mile area, including the central part of Chicago and 46 suburban communities. The Stickney WRP cleans 700 million gallons of water per day, with the capacity to treat up to 1.44 billion gallons per day.

What The MWRD Has Learned About Wastewater Treatment

A video tour of Stickney

"Content includes the history of the MWRD and how it reversed the flow of the Chicago River, which is brought to life with historical imagery from the MWRD's archives. The tour provides an in-depth look at wastewater treatment, including underwater and microscopic views of the process. Aerial drone footage captures highlights of the construction of the Tunnel and Reservoir Plan in addition to property the MWRD leases for recreational uses."

No comments:

Post a Comment