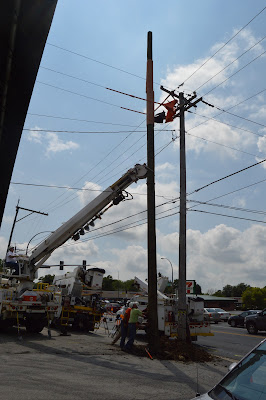

In this overview scene, we see they have already installed safety insulators on the wires that go east from the pole in front of the Domino sign.

|

| 20180817 3880 |

I put a yellow rectangle around the end of the boom that caught my eye because the end was moving back and forth.

So as I walked across the intersection, I got an overview of the Action. From left to right, they had small and large bucket trucks and a digger derrick.

I got a view of the auger as I walked around the trucks.

The lady with the blue instrument had "Nicor" on the back of her high-visibility vest. It is obvious that she is marking where the gas pipes are. At this point, I switched to video.

Something broke on the auger, so they stopped for a closer look. They decided that they needed to call a mechanic to fix the problem. So while they waited, I took some additional shots. Below is an overview from the other side.

Equipment that will be needed on the top of the new pole is stored at the edge of the parking lot...

...except for the crossarm that is tied to the old pole.

A closeup of the protection equipment they have installed on the wires. One of the workers explained to me that the wires carry 7,200 volts compared to ground. And there is 12,000 volts between the wires (between phases).

A closeup of the business end of the boom truck since it was readily available.

The work they had done so far.

This is the next pole south. The location of the new pole should reduce the overhang on this pole. I wonder if that is why they are putting in a new pole because the current one looked OK (to my untrained eye).

When I got back, they were drilling, so I switched to video.

You saw during the video that a truck drug the new pole into place. So I again switched to video for the lifting of the pole. As I mentioned in the video's comments, they had the challenge of working around a low phone cable and a building at one end of the pole.

In this video of them installing the pole, note the clamp attachment at the end of the boom. It is normally folded down, and I had not noticed it until they started to use it. That is what holds the pole when they place it into the hole.

13:24:27 I switched from video to a series of photos because they had to work slowly on the final placement of the pole. Note that the top of the pole is between two of the high tension wires. They have slipped on insulators as a precaution, but they would rather not hit one of the wires. I zoomed in on the pole clamp attachment at the end of the boom.

|

| Digitally Zoomed |

|

| 13:24:42 |

|

| 13:24:52 |

|

| 13:25:00 |

|

| 13:25:28 |

|

| 13:26:00 |

|

| 13:26:10 |

|

| 13:26:22 |

|

| 13:26:28 |

|

| 13:26:34 |

|

| 13:27:03 |

|

| 13:27:11 |

|

| 13:27:20 |

|

| 13:27:43 |

|

| 13:27:54 |

Then the activated liquid is poured into the hole.

13:30:17 A crew member was kind enough to explain that the liquid is a foam that will expand to fill the gap between the pole and the undisturbed earth.

13:33:03 After the first batch of foam quit expanding, they activated a second batch of the foam chemical...

...stirred it in...

...and poured it into the hole.

13:34:13

13:35:50 I was straining to see what was happening in the hole from my safe distance, so one of the crew indicated I could get closer to take photos of the foam since nothing was happening while they waited for the foam to set up.

13:36:33

Remember when I said something on the auger broke and they had to call a mechanic? This is the mechanic leaving with his special truck.

Now that the foam is rigid, they release the pole clamp. Notice the near clamp arm in the open position.

|

| Digitally Zoomed |

They lowered the cable by lowering the boom rather than letting more cable out.

I believe the worker on the right is the boss. I always appreciate watching a crew where the boss pitches in and helps with the grunt work. In this case shoveling dirt back into the hole.

A closeup of the pole clamp in its folded transport position.

13:40:04 The cable is stowed and the shoveling continues.

(new window) The fact that the boom has already swung half way around shows how long it takes me to switch the camera from photo-mode to video-mode when I'm caught by surprise.

The pad at the end of the outrigger automatically folds vertically to reduce the width of the truck during transport. The operator is now raising the front outrigger.

The metal pads for the outriggers are lifted and stowed in slots under the truck.

14:01:47 An overview of the trucks after all of the tools have been stowed away. From left to right, a digger derrick truck, a non-overcenter aerial truck, and an overcenter aerial truck.

After the digger derrick left, I got a better view of the two aerial trucks.

14:23:45 A junior member of the crew waited with the smallest (cheapest) truck until the traffic barricade subcontractor arrived to open up the traffic lane on Belmont that was blocked for this work.

When they were installing the new pole, one of the crew members explained that they would be back at midnight to move the wires. They had to move the wires later because they turn off the power to the neighborhood while they work on the wires. When I arrived around midnight, I saw six trucks in the area.

I had the ISO of the camera cranked up to 6400. That was OK for taking photos of a crane disassembly between midnight and 7:00 because the signs and street lights were still on. But I learned that when they cut power to the neighborhood so that even the traffic lights are out, ISO 6400 is not good enough. I include this photo because you can faintly see the spool of cable on the trailer being pulled by the truck.

A few blocks north they had a small over-center aerial truck parked on Ashley and another on Belmont.

They also had a large off-center aerial truck parked on Belmont.

This is the pole they were working on, but I evidently jerked the camera during the slow shutter speed.

Between Ashley and the new-pole work was this pole. If you look at the base, you can see a new crossarm and other equipment. Later, a couple of the aerial trucks will work on this pole while work is happening on the new pole. I counted up to five aerial trucks on this project. It makes sense that when they cut power to a segment, they do all of the repairs needed on that segment while the power is out to minimize outages for their customers.

I believe the crew member in the raised over-center aerial truck is using a device to verify that the wires are, in fact, deenergized. A crew member is loading tools and equipment such as a crossarm, insulators, bolts, etc. into the bucket of the off-center aerial truck. I saw a label of "700 pounds" on that truck's bucket. I assume that is the maximum lift capacity. Note how the tool compartment has interior lighting. That is important because it is really dark when they pull the power. Not even the traffic lights were working. I was surprised how much ambiant light there was from store signs, etc. before the pulled the power.

(new window)

Then the other aerial truck joined the work so I had a ballet of bucket trucks.

I had been asked by a worker not to take photos. When I asked him for his business card, he said "I'm not saying you can't take photos, I'm saying I would appreciate you not taking photos." I explained that this a rare opportunity to get shots of this equipment because I'm not going to go out in a thunderstorm to get them. As you can see, I did take some photos and video; but I soon left. Partially because someone did not want photos taken, but mainly because you can't see anything anyhow. I think this is the photo I took of the worker in the off-center aerial truck boring a hole in the new pole with a big, long bit.

No comments:

Post a Comment