I didn't realize that bricks were made in the Western Suburbs until I read the post below. I knew there was a lot of brick manufacturing around Goose Island,

South Chicago and in Streator, IL after the 1871 Fire because of a city ordinance that ruled out reconstructing with wood. [

DeBruler]

The house that William L. Gregg built for himself with one of this first batches of bricks has been preserved in Westmont (

Satellite).

|

| 20190925 9459 |

|

Forgotten Railways, Roads & Places posted

Westmont Station was originally known as "Gregg".

Nothing was more important in paving the way for future Westmont than the building of the Chicago/Aurora branch of the C.B. and Q. Railroad, begun in 1862 and completed two years later. At this time, a large share of the future Westmont was bought up by the Phipps Industrial Land Trust. Shortly after the Chicago Fire of 1871, some of this land was sold to a number of brick manufacturers jumping at the chance to supply bricks for the rebuilding of Chicago.

The most memorable brick manufacturer was William L. Gregg who chose the highest point of land along the C.B. and Q. Railroad for his company so that shipping by steam locomotive would be downhill with a full load of brick. In the spring of 1872, Gregg began manufacturing bricks under the name of Excelsior Brick Company. His company started with a capital investment of $250,000.00, employed 120 people and produced 70,000 bricks a day. While here, Mr. Gregg invented and patented a triple pressure brick machine which revolutionized the brick industry. Using this method, his bricks could withstand 100,000 pounds of pressure without cracking or disturbance of any kind.

Gregg built his home to showcase his product. Records indicate he lived in the home for approximately three years. He considered himself a dealer in patents as he invented sixteen different pieces of brick making apparatus.

By 1900, brick making declined. The area continued to grow and the flag-stop on the “Q” was known as “Gregg’s Milk Station”. The name of the station was shortened to “Gregg”.

After Gregg left the area, the home had various owners and was used as a farm house, restaurant, funeral home, speak easy, and recreation center. Later it was owned by Holy Trinity Catholic Parish and used as a home for a priest for a short time before becoming home to several nuns.

Eventually the home became run down and was going to be demolished. In 1976 the Westmont Area Historical Society was formed to save the home. It was moved one block from its original location on Cass Ave. to its current location on Westmont Park District property. After extensive restoration, it opened as a museum in the fall of 1981.

History via: https://www.westmontparks.org/parks-facilities/gregg-house-museum/ |

The oral presentation at the museum provided some more information. Gregg was living in Philadelphia when he heard the Chicago rebuild could not use wood and would need a lot of bricks. So he moved to the Chicagoland area to be a part of the rebuild economy. The 80-acre parcel that he bought was typical for the day. His house was originally on Cass. The Holy Trinity Catholic Church owned it and actively used it. But in the 1970s they wanted to tear it down to expand. The Westmont Historical Society was formed, and they moved it a block East. Since the new location was still on the original 80-acre plot, the 1977 move did not invalidate its inclusion on the National Register of Historical Places in 1980.

Gregg designed and built is own equipment to mix, cut and dry the bricks. His machines to mix and cut the bricks ensured that they were of a consistent composition and size. His kiln was designed to dry all of the bricks in it at a uniform rate.

The home of William L. Gregg was constructed in 1872 with bricks manufactured in the newly operating Excelsior Brick Manufacturing Company. Gregg's brickyard, a large and carefully located one for that time, employed 120 workers and manufactured 70,000 bricks a day. Mr. Gregg also invented the triple pressure brick making machine, which revolutionized the brick making industry. He died in 1891 and a few years later, the Excelsior Brick Company ceased production. [Brochure]

I have determined that the above topo excerpt was from the 1901 Riverside Quadrangle @ 1:62,500. The left side of the excerpt is the left side of the quadrangle. The oldest topo for the Westmont area is 1891:

|

| USGS 1891 Riverside Quadrangle @ 1:62,500 |

By 1927, the suburbs along the CB&Q had "filled in."

|

| USGS 1927 Hinsdale Quadrangle @ 1:24,000 |

I took a couple of photos of the garden that is behind the house.

They had three (glass covered) frames for the diagrams and text of some of his patents.

A kiln:

A "Brick Mahcine:"

A drying building:

Each Summer they have a different theme for the exhibits in their two front rooms. This year was transportation. So one room was about the CB&Q Railroad.

This is the first time I've seen Lisle included in the list of existing western suburbs. And Hinsdale had a different name. But now I can't remember it. Bush Hill is what is in my brain cells. But I don't trust them.

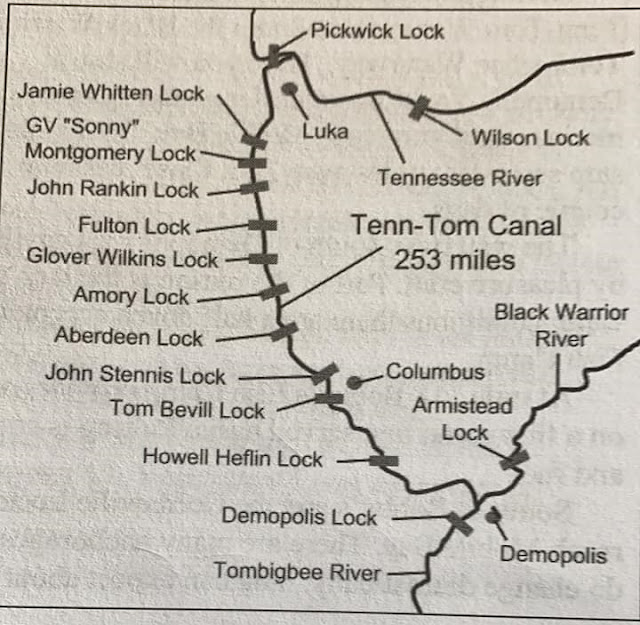

The second room was about the I&M Canal.

Two closeups to try to get a readable resolution of the facts. If you click an image and use your browser's F11 option, you should get a better view.

This display includes historic and current views of the

Fox River Aqueduct in Ottawa, IL.

I took this image for my

Gaylord notes.

The museum is full of permanent exhibits of "old things." This is just a sampling. Note the washing machine. The stove had gas burners. They had a sign that explained the temperature of the two ovens was not automatically controlled. Each oven had a thermometer, but a human would have to adjust the controls to maintain the correct temperature. The compartment on top was a warmer.

Early cathode ray tubes were round because that was the strongest shape to withstand the pressure of holding a vacuum inside.

Most old cash registers I have seen are quite fancy. I'm sure this is more representative of what was actually used.

The oral presentation explained that

the ball park south of the house was the clay pit for the brick factory. The diamond was visibly lower than the surrounding land. I took a couple of photos to try to capture the slope of the land along the edges of the diamond.

I found myself parked in, so I had to kill some time. I walked down past home plate to take another photo to try to capture the fact that the diamond is in a pit. That is Gregg's House in the middle of the photo. A park district building is to the right of the house.

During the oral presentation, I was showed one of the bricks he made. I knew that the markings on a brick are important to brick collectors. So I went back in to get some close ups of the demonstration brick. Note that the S is backwards.

|

| Image taken with permission of the Gregg House Museum |

|

| Image taken with permission of the Gregg House Museum |

|

| Image taken with permission of the Gregg House Museum |