"Washington Steel was the first U.S. company to use a Sendzimir Mill to cold-roll stainless steel." [wikipedia]

The small work rolls allows the rolls to be made with stronger metals such as titanium because the smaller size is more affordable.

|

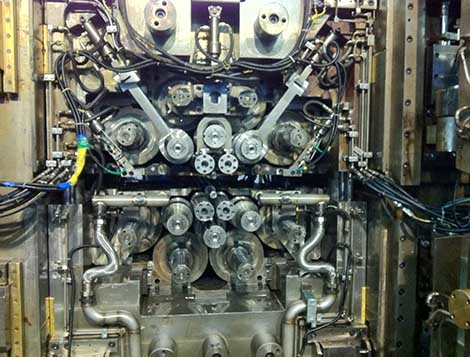

| Jon Wolfe posted Jim Adkins: We had a 49" Z mill in Massillon Republic Steel Stainless mill. Edward Hollis: Wrecked and rebuilt ATI’s #8 zmill many times. Good memories [There are several comments about how clean this looks.] Francis Coleman: Eligiloy specialty metals in northern Illinois. Francis Coleman: The 4 big ones are bearings the 3 are drivers, the 2 are lateral rolls, that's wear your shape is adjusted with the hydraulic crown adjustment and the 2 little guys are the work rolls 😁 Just the work rolls get changed multiple times a shift. We would change lats and drivers weekly and bearings based on time. Jonathan Wallace: Z mills are kind of amazing. Worked on the one at ATI Louisville when I was there for six months. It was something when it would crash. |

Of the three diagrams I have seen, this is the only one that doesn't have mistakes that are obvious to me. Note that the backing rolls at each level touch the rolls below but not each other.

|

| Waterbury Farrel Brochure, p4 |

This diagram incorrectly shows the backing rolls touching each other, but it shows which rolls are driven and the two small work rolls.

|

| pinterest and LibraryOfManufacturing |

The small work rolls allows the rolls to be made with stronger metals such as titanium because the smaller size is more affordable.

|

| Waterbury Farrel Brochure, p4 |

|

| IndiaMart Waterbury Farrel Corp. Model Zr23-19 |

|

| hanrm The work roll has a small diameter and the pass reduction rate is high, up to 60%. Some materials can be rolled into very thin strips without intermediate annealing. |

|

| Waterbury Farrel Brochure, p1 |

|

| Derrick Ream posted Z31 Louisville Ohio . Ati now owns this mill but used to be JL. Sendzimir mill ( zmill ) [A comment explains that the two work rolls are not in.] Michael Thomas Fagan: ..we have a 54",64", and 74" @ CRM. Andy LaRowe: As a "4high" guy this is neat to look at. How many stands are there and how wide? ( Curious) Dave Jaap: Andy LaRowe no stands. It's one unit cluster reversing mill. Work rolls, drivers and idlers, tapers, and back ups. It's called a Sendzimer or Z mill for short. Pretty sure new mills go real wide. Ones I've been a part of were 50 wide at Washington Steel and J&L Midland. Pat McCon: Andy LaRowe https://www.hanrm.com/pro.../sendzimir-20-high-rolling-mill/ [There are a lot more comments on this post.] |

|

| Randy Berisford commented on Derrick's post Z8 |

|

| Bob Clementi posted Sendzimir rolling mill [Several comments indicate where they worked on a Z-mill.] |

|

| Karl L. Brendle commented on Bob's post Derrick Ream commented on Bob's post Z31 Louisville Ohio . Now gone |

|

| Jake Butler commented on Bob's post |

9:22 video At 3:58 they show the rack moving. I assume that controls the gauge. But I have yet to figure out how that works.

An interesting summary of the mill types.

|

| ispatguru |

2:37 video

I use to make cluster mills for Intergrated industrial systems in Wallingford Connecticut. It’s a machine not many can machine. If u machined these your a bad ass machinist. I was. Name is Robert Burns. The housings themselves weighed 90 tons. Cost. About 20 million depending

ReplyDeleteMy boring bar that cut the radius cuts on the sides weighed 17 thousand pounds. It was passed two fixtures. One in the front and one in the back to cut it straight

ReplyDeleteU want me to build. One for u. Call 561-201-1765

ReplyDelete