The dome of the hot stove next to Furnace D exploded off the top. There were enough photos about the explosion and its repair to justify some separate notes about the explosion.

|

| Mike Brady posted From a 1978 Bethlehem brochure, front cover. Dan McCusker: Will Glick Sr. How was it being an electrician at a mill? I am a two year journeyman electrician myself but I’ve never done any industrial. Mostly all commercial and apartments. Been looking to try out something like this just because I’m feeling a little burnout on what I’m doing now. Just don’t feel quite challenged enough. Will Glick Sr.: Dan McCusker Its not just a job… it’s an adventure. It’s what you make of it. It takes years to get to know the different equipment especially the electric drives. Old and new technology and equipment. A lot of things have changed in my 36 years. Computer’s, solid state drive units combined with more electronics, variable frequency drives to mention a few. In the Sintering Plant there are two 9000 HP synchronous motors that run on 13,800 Volts and some 400-900 HP motors that run on 4160 volts. In a steel mill you also have to deal with hot and cold temperatures and / or dusty conditions. When I said it’s an adventure I was not kidding. For me this is where I belonged. Not the kind of job for everyone but it’s different for other industries other than steel mills. Not all of areas of the steel mill are like the blast furnace/ raw materials handling department as far as the heat / cold and dust but that’s what kept it interesting to me. Lol! If you’re really interested check out some local industries especially the smaller ones, they may give you some insight and maybe a tour of the facilities. Let the adventure begin! Good luck to you! Mark Goodrich: Only one caster back then and no hot dip galvanize line. Will Glick Sr.: Mark Goodrich no Coal Injection facility for the blast furnace’s either. |

|

| Dave Vass posted Joe Vass rolling the first plate of steel @ Bethlehem Steel In Burns Harbor Indiana Andrew Jackson: That slab is in the ground in front of the 160” plate mill office. Ron Casaday: Some of that equipment is still in and being used in the 4 hi pulpit. Dave Vass: Check out the counter, it reads “01” indicating it is the first slab ever made there. Dad was hired on the first day of hiring and had the highest scores in his training class, which qualified him to roll the first plate. I think it was the 160 roll line. This picture was from a company calendar that he had hanging in his Man Cave. Dale Hinds: Would I be correct in assuming a family relationship between the author of this post and the rolling mill operator? Dave Vass: Dale Hinds Yes, I was 5 years old then. Jerry Szymanski: November 30th 1964 first plate the day I hired in stayed there 46 years wow |

|

| Jon Wolfe posted Burns Harbor |

.jpg) |

| Paul Santiago posted Overlooking Burns Harbor BOF and Caster Building. Watched and worked in the BOF while it was under construction. Put 49 years there and was called back for another 5. |

|

| Ted W. Makropoulos posted Fred Baginski: "3000 acres of land, neighboring US Steel’s Gary works, were purchased and construction started in late 1962. Probably few could have imagined that Burns Harbor would be the last integrated mill in the U.S. to be built until today. In 1964 the 160 “ plate mill was started followed in 1966 by the 80” hot strip mill. In between 1969 and 1972 two blast furnaces, a coke plant (164 coke ovens) and a steel mill, containing two 300 ton BOF vessels were started. In 1975 Bethlehem Steel’s first continuous slab caster started production. In 1978 a 110” plate mill and a third BOF vessel became operational. In 2000 the last ingots were poured." http://www.steel-photo.org/.../burns-harbor-the-last.../ Mr Richard posted Winda Yunita Kudadiri posted |

|

| railroad_journal posted Aerial view of Cliffs Burns Harbor, formerly Bethlehem Steel. (Dr. Raymond Boothe collection). In 1962, Bethlehem Steel Company from Pennsylvania began construction of a state-of-the-art integrated steel mill on Lake Michigan. The site encompassed 3,000 acres of land east of US Steel’s Gary works, next to what would become the Port of Indiana - Burns Harbor. This was the last integrated steel mill be built in the United States. An integrated steel mill processes raw materials, such as iron ore, to produce steel from scratch through a multi-step process that includes coke making, iron making in a blast furnace, steel making in a Basic Oxygen Furnace (BOF), and then rolling the finished product. This differs from mini-mills, which primarily recycle scrap metal using electric arc furnaces (EAFs). In 1964 the 160” plate mill was started followed in 1966 by the 80” hot strip mill. In between 1969 and 1972 two blast furnaces, a coke plant (164 coke ovens) and a steel mill, containing two 300-ton BOF vessels were started. In 1975 Bethlehem Steel’s first continuous slab caster started production. In 1978 a 110” plate mill and a third BOF vessel became operational. In 2000 the last ingots were poured. After filing bankruptcy Bethlehem Steel was taken over by the International Steel Group (ISG) in 2003. Two years later Burns Harbor became part of Mittal Steel USA (ArcelorMittal since 2007). On December 9, 2020, Cleveland Cliffs LLC. purchased the ArcelorMittal Burns Harbor facility. The facility is now known as Cleveland Cliffs Burns Harbor LLC. The Cleveland Cliffs Burns Harbor is one of the largest fully integrated steel mills in North America, with the capacity to produce 5 million tons of raw steel per year. |

|

| safe_image for ArcelorMittal Burns Harbor, Indiana by Viktor Macha [Viktor travels the world taking photos of steel mills. This page has quite a few photos.] |

|

| Christian Thomas posted Hey everyone, Just had a question regarding currently operating blast furnaces around the Great Lakes. The ones I know of are Hamilton, Nanticoke, Cleveland, Sault Ste. Marie and Burns Harbor, Gary Harbor and Indiana Harbor. Could someone let me know if I missed any? Thanks for any info. The video is from Burns Harbor. Mike Stephenson: Algoma shutting down BF as EAF just started up. Dave Greenfield: middletown, ohio Don Mc Carthy: Dave Greenfield more than 100 miles to the lake. [Given their transportation costs for raw materials, I don't understand why this one is still running.] |

|

| Robert Rice Sr. posted Burns Harbor: the last integrated steel mill built in the United States. |

|

| Chris Morris commented on Robert's post If I remember correctly we all got this as a 20th anniversary gift from the company in the early 80s, 1982-ish? |

|

| Janet Ruth Howard posted Cleveland Cliffs Burns Harbor. Riley Drumm: Old old old picture but awesome. |

This is the first time I've seen a flare burping fireballs.

|

| Steve Buckner posted Burns Harbor |

Mike Brady posted the complete 1978 brochure.

|

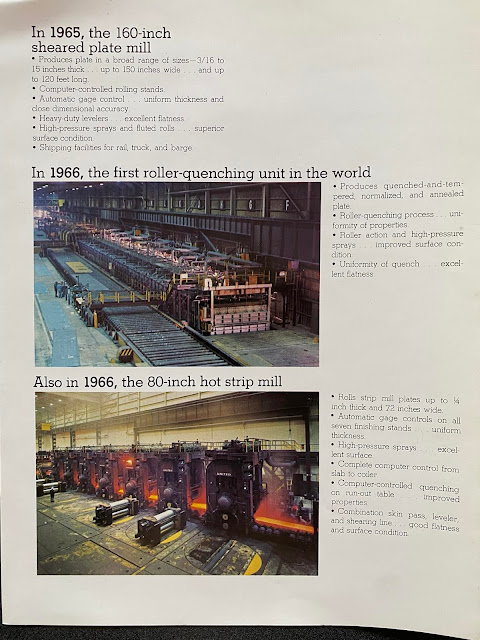

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| Chris Morris posted It's been pointed out this was for the 25th anniversary of the ground breaking at BH (1962), so received it in 1987, which was around my 20th. James Torgeson: Note there were two versions of these tinplate trays for both Burns Harbor and Sparrows Point. The originals featured the traditional Bethlehem logos, while the newer versions featured the dune grass Burns Harbor logo or the lighthouse Sparrows Point logo. James Torgeson: Chris Morris The Burns Harbor Plant with the 1000' M/V Burns Harbor at the ore dock! |

Lou Gerard posted two photos with the comment: "Arcelor Mittal Burns Harbor plant, August 2016. Taken from a WWll B25."

|

| 1 |

|

| 2 |

By the time I started writing this blog in 2014, Burns Harbor was one of the steel plants in Chicagoland that was owned by ArcelorMittal (AM). In 2020, Cleveland-Cliffs (C-C) bought all of those plants from AM.

|

| safe_image for Michael Harding Flickr Working the mill Lake Michigan & Indiana Railroad #203 is pulling coil cars out of the massive mill complex at Burns Harbor to place in the interchange yard. Only a relatively small portion of the sprawling complex is visible even at this height but the blue waters of Lake Michigan can be seen beyond the mill. Burns Harbor, IN 8/24/2022 |

|

| David Schaeffer posted Cleveland Cliffs Plate Mill, Burns Harbor, IN |

|

| David Schaeffer posted Cleveland Cliffs, Burns Harbor, IN Johnny Patrick: Good ole Coke plant |

|

| David Schaeffer posted Cleveland Cliffs, Burns Harbor, IN |

Two sides of an Indiana Historical Bureau Marker:

Bethlehem considered building a steel operation in Northwest Indiana in 1906 in Lake County and in the 1920s in Porter County, but the costs were deemed to be too high. (I recognize the 1906 date as when US Steel built the Gary Works.) "In 1956, Bethlehem Steel decided to move forward with construction plans. They formed a subsidiary to quietly purchase land in Porter County near Lake Michigan. The Lake Shore Development Corporation eventually purchased over 3,000 acres of land. In 1962, the company announced its plans to build a finishing mill on the site. The Burns Harbor Finishing Mill commenced operations in 1964." The Federal government created the Port of Indiana in 1965 and shortly thereafter Bethlehem added a Primary Production Facility (PPF) at this location. [OrangeBeanIndiana] Until the PPF was built, steel was shipped to the rolling mills from their eastern locations.

This is a good article about the social aspects of Bethlehem's history. Basically, the executives were more interested in their perks such as gold nameplates than the innovations in the steel industry. I just skimmed it, but the information about Nucor helped put things in perspective. It also documents some of the iron ore mines that existed in eastern United States. Significant parts of the article are very appropriate for reading on Labor Day.

|

| Raymond Boothe posted Aerial view of Cliffs Steel (formally Bethlehem Steel) Burns Harbor Blant (Dr. Raymond Boothe collection). |

|

| Rick Catania posted Took this photo of #7 Blast Furnace from Whiting Park. March 8, 2022 NIKON 200-500 5.6E ED VR James Torgeson shared Cliffs Indiana Harbor #7. Ed Goodale: That’s some good zoom you got there. Whiting Park about a mile away Jason Williams: With #4 on the West Side being idled they are expecting alot out of Madeline/#7. They want to see if we can Cast 13,000 tons of iron a day. We will be feeding 3 BOF's. Allan Phillips: Ray Belcher I was hired in 1980 as one the first engineers there. It’s the largest in the Western Hemisphere at 45’ hearth diameter, 40 tuyeres. The initial blow-in was a bear, as the biggest furnace Inland had before that was 26’, lots of learnings about big furnaces. |

|

| Allan Phillips commented on James' share Here’s one I took in summer of 1980, before its startup. Look how clean! |

|

| David Schaeffer posted Cleveland Cliffs, Burns Harbor, IN Kirk Hayes: Pictures taken from j5? Patrick Goughler: Kirk Hayes No, J5 is visible in the lower right |

|

| Remo Gonzalez posted Cliffs,Burns Harbor Furnaces |

%20Steel%20Mill%20Pictorial%20_%20Cliffs,Burns%20Harbor%20Furnaces%20_%20Facebook.png) |

| Comments on Remo's post |

|

| Mario Tarabuio posted Phoenix couple working at BH blast furnace! [Some comments indicate the steam is coming from a slag granulator or "popcorn machine" rather than the bleeders.] |

|

| Raymond Boothe posted Cliff Steel- Burns Harbor Con Caster (Macha Photo). |

|

| Terry Hiestand posted Bethlehem, number one caster. 1975 Burns Barbor |

|

| Raymond Boothe posted Cliffs Steel-Burns Harbor Coke Plant (Macha photo). |

|

| A coke-push post that got deleted from Facebook before I could access it. |

|

| Phil Jadlowiec posted Sharing from another group. Will Glick Sr.: Did some special testing of Coke Quenching back in the 70s when I was in the Chem Lab. |

|

| Ryan Boots posted Iron producing Cliffs Burns Harbor. Ravi Eh: How many tuyeres per furnace ? Ryan Westman: Ravi Eh 28 on both |

|

| For Burns Harbor, Cleveland-Cliffs will be the fifth name change in its 50-plus year history. (E. Jason Wambsgans/Chicago Tribune) |

A two page 1966 ad: ($400m in 1966 is worth $3.37b in 2021. [calculator] And this was just the rolling mills. The total investment was more like $1b ($8b today).)

|

| 1 |

|

| 2 |

They are starting work on the Primary Production Facility in this photo.

|

| Refrigerator Magnet |

|

| SteelNerd 1: Blast furnace C, 1969 [BurnsHarbor, Building Bethlehem Steel tab] 2: Blast Furnace D, 1972 [BurnsHarbor, Building Bethlehem Steel tab, about 10,000 tons/day] 3: Ore storage, 1969-72 4: Coal Storage, 1969-72 5: Coke plant, 1969-72 6: Sinter plant, ? 7: BOF shop, 1969-72, two 300-ton BOF; 1978 third BOF 8: Slab caster 1, 1975 9: Slab caster 2 10: 80″ hot strip mill, 1966 11: 160″ plate mill, 1964 12: 110″ plate mill, 1978 13: Cold rolling [and tin] mill, 1966 [The last ingots were poured in 2000.] |

The plant has two blast furnaces, as well as two, 82-oven coke batteries. Sheds contain plate and strip mills, coating lines, annealing and tempering mills, and other treatment facilities. It provides steel to the automobile, tube, pipe, shipbuilding, drum, appliance, HVAC, tank, and rail car-making industries. Bankrupt Bethlehem Steel was bought by ISG for $1.5 billion in 2003, and Mittal bought ISG for $4.5 billion in 2004. So like the big mill at Indiana Harbor, Burns Harbor is also owned by ArcelorMittal, the largest steel company in the world, based in Luxembourg.

(These photos are kinda old because the NIPSCO Bailey Power Plant is still active.)

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

"The opening of the Burns Harbor plant came just before a major turning point for the US Steel Industry. It was the last integrated steel mill to be built in the US. Unfortunately, the late 1970s and 1980s saw the American steel industry struggle due to foreign competition and large draws from their pension plans." [OrangeBeanIndiana]

|

| BurnsHarbor, Building Bethlehem Steel tab |

|

| Bill Mergl posted Here’s one I took looking at Bethlehem from the stack at the power house ! Shaun Connelly: From nipsco? Must be a older photo the slag piles look small lol. Bill Mergl: Shaun Connelly yes changing lamps on the stack March 2014 |

James Torgeson posted three photos with the comment: "The former Bethlehem Steel flagship Stewart J. Cort unloads 58,000 tons of Hibbing Taconite pellets at Cliffs Burns Harbor."

|

| 1 |

|

| 2 [A stacker/reclaimer in the background.] |

|

| 3 |

|

| 1 |

|

| 2 |

|

| Bill Dufault posted C furnace Burns Harbor, from bleeder change on D. 8-20-2014 The best furnaces ever built. If you took this picture today, that far plume of steam is from me in the quench! [So they make their own coke.] Is the coke plant off in the distance? #1 battery quench tower in deluge |

|

| Tom McKee posted Burns Harbor 2019; looking from the Bedding Plant NE- Blast Furnace on left and Power Station on right. Brown on the ground and blue in the sky. |

|

| The Beauty of Steel project posted Burns Harbor "C" blast furnace in 2015 and in early 70´s. The last integrated mill ever built in the US (so far). IG: @ viktormacha |

|

| The Beauty of Steel project posted The blast furnace C as seen from the blast furnace D at Burns Harbor works. Back in 2015 I got a rare chance to visit the ArcelorMittal USA sites within my documentary project. I was so hoping to return this year, but it turned out that Cliffs don´t like photographers the same way as the USS do. Shame. More images from my visit: https://www.viktormacha.com/.../arcelormittal-burns.../ |

|

| The Beauty of Steel project posted This is where the molten metal/pig iron transforms into the steel. The process is called basic oxygen steel making. Pure oxygen is blown into a bath of molten blast furnace iron and scrap. Easy. No magic, yet very magical to look at. I asked the worker to stand next to the 350t BOF vessel to demonstrate the monstrous scale. Taken back in 2015 at Burns Harbor, IN works. https://www.viktormacha.com/galerie/arcelormittal-burns-harbor-indiana-297/Sandeep Sahoo: Interesting scrap charger Viktor Mácha At the Burns Harbor BOF shop during my steel tour back in 2015. 8 years ago… time to come back to the US I guess! |

|

| Jessica Van Giana posted Charging a 300 ton BOF at Burns Harbor back in the day. Mostarifa Mostarifa shared |

|

| Willy Gee posted Brand New BOF Furnace for installation at Bethlehem Steel/Burns Harbor. AKA Cleveland Cliffs December 19 2022 Brian Strong: That is for #3 furnace Michael DiPasquo: When is it going in? Willy Gee: Michael DiPasquo The Job has not been awarded yet. Still up in the air. Mike Spence: It’s all rust now saw it last week. [A brand new one is already rust???] David Czapla: Sitting outside rusting away. What an investment. Jason Parham: David Czapla that surface rust isn't hurting anything. put a couple of heats through it and that paint will be burned off anyway. Josh Lugar: Well if it’s like any of the other parts we have gotten from primetals it’ll be trash and have tons of issues and need special parts that they only have.. Justin Braden: Hopefully their BOF's run better than their EAF's lol El Boiler Smith: 374 [I presume that is its capacity in terms of tons.] Tom McKeon: Truck Drivers still call it Bethlehem too ! If you want your stuff delivered to the right place its Acme Steel - US Steel - LTV - Inland Steel and Bethlehem Steel . John Groves: At its peak, Bethlehem Steel Corp. operated the following plants (with maximum annual capacities in brackets)...... Bethlehem (3.9 million tons per annum) closed 1995. Sparrows Point (8.2) closed 2012 Lackawanna (6.0) closed 1983 Burns Harbor (5.3) still operating Johnstown (2.4) closed 1992 Steelton (1.5) still operating There were also three small scrap-based mills at San Francisco, Los Angeles and Seattle (each less than 0.5). Of these only Seattle is still operating, as part of Nucor. Lukens Steel was acquired in 1997 (1.0), and is still operating as part of Cliffs. At its peak, Bethlehem Steel had a raw steel capacity of around 27 million tons per annum and ranked as the world's second largest steel company. |

Until I learn which USS works this was at, I'll park the information here.

%20Steel%20Mill%20Pictorial%20_%20Brand%20New%20BOF%20Furnace%20for%20installation%20at%20Bethlehem%20.png) |

| Comments on Willy's post |

|

| John Smith posted Clear and cold this morning [Nov 18, 2021] in Burns Harbor. Gregg Leech: D furnace. |

|

| Bob Gallegos posted Cliffs Steel bucket loader. Burns Harbor, IN 20220228 ©Bob Gallegos James Torgeson shared Will Glick Sr.: This is #3 stacker, it was #4 that fell March 12, 2014. |

|

| 0:42 video (source) Nathan Bantsolas: C and D blast furnaces off in the distance. |

|

| Bryan Eschbach posted ‘C’ Blast Furnace Bryan Eschbach shared Jay Sharpe: It's having a smoke break. George Goble: Is that a pressure relief value? [unfortunately, no answer] |

|

| Nathan Bantsolas posted, cropped Cleveland Cliffs Burns Harbor… taken a few years ago when it was Arcelor Mittal … C and D blast furnaces |

|

| Aaron Pena posted Reduction box that serves the 80"" Hot Strip at Burns Harbor, IN. |

|

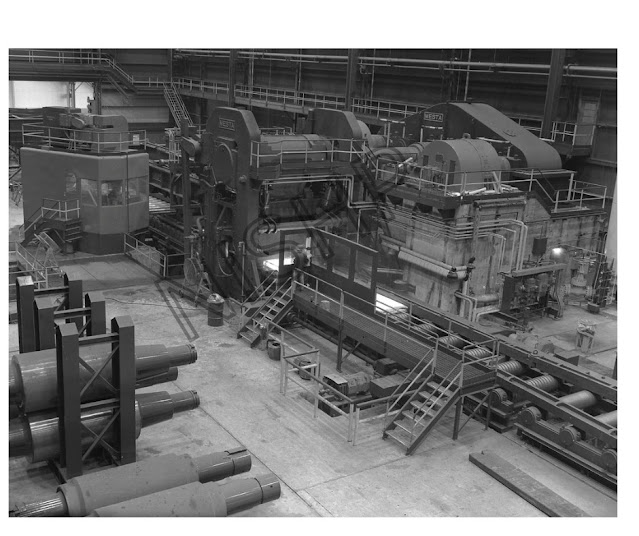

| Robert Meyer posted Another early shot of the Burns Harbor 80" HSM (Dave Mergl photo, NISHP collection) Jean-Pol Masina: finishing stand |

Anthony Wheeler posted four photos with the comment: "Some quick pics from a couple years ago. Former arcelormittal burns harbor coke plant, with beautiful Lake Michigan in the back ground. Details in captions."

[The comments have some interesting information: there are 82 ovens per battery and each oven "cooks" 32 metric tons for a minimum of 18 hours. Battery #1 was built in 1969 and the coke plant has been a money maker. There is also a discussion of how the Larry Car lifts a lid, discharges coal, and then seals a lid.]

|

| 1 On top of #1 battery coal bin looking north |

|

| 2 Same location looking north east Bill Hill: Nice picture of the old Songer yard on the right as well. |

|

| 3 Same location looking east |

|

| 4 Same location looking northwest |

|

| Gabi Buhus commented on Anthony's post Put together the images make a great panoramic view of the mill |

The piles of black stuff (coal), as opposed to brown stuff (iron ore), made it easy to find the coke plant on a satellite image. I left the "Dray fertilizer loadout building" active on the satellite image because I did not realize that one of the byproducts of coke making is dry fertilizer. I do know that gas is one of the byproducts. In fact, in the 1800s coke plants were built to get the gas and coke was considered a byproduct.

|

| Satellite |

|

| Mike Hilzley posted #2 Continuous Slab Caster Bethlehem Steel Burns Harbor Plant Start-up 1985, later became, ISG, Mittal, ArcelorMittal, and now Cleveland Cliffs |

|

| Will Glick Sr. posted Both C and D furnaces down at Burns Harbor 2013 due to stupid miss management. Chris Merry: I'm working on D3 stove. They are definitely running and looks like they will be for quite a while based on the $ cliffs is spending. [Comments offer books describing how a manager killed the Weirton works.] |

|

| David Schaeffer posted Cleveland Cliffs, Burns Harbor, IN Chris Benedict: I’ve delivered a lot of lime to that place. Spent many hours there waiting to unload lol Brian Katzmarek: That new granulator on D furnace is a POS. |

|

| Will glick Sr. commented on David's post Spent many hours on # 3 Stacker/reclaimer as an electrician in my 36 years in the Raw Materials Handling section of the Iron Producing department . |

|

| Ashanti Gillette posted Curious what the front-end loader is moving here. John Flint: Just pushing the pile up to be reclaimed easier. |

|

| David Schaeffer posted Cleveland Cliffs Mill, Burns Harbor, IN. Paul Carnahan: I hate that stacker, sucks changing a gearbox on New Years Eve, at night, during a blizzard, 50 ft up, with wind blowing... Dan Mills: Paul Carnahan 🍼 [The icon is more obviously a baby bottle on Facebook.] |

.jpg) |

| Paul Carnahan commented on a comment the one right in that area... |

Anthony Carter provided two photos in comments, but I think it was a different repair job. (There is some bad blood in the comments, and I didn't bother to understand what they are talking about.)

|

| 1 Pretty sure I was higher than 50' felt like it |

|

| 2 |

Ryan Boots posted two photos.

Will Glick Sr.: I worked on this one , #3 stacker. Knew it well.

Tomm Alsman: Most maintenance people at Burns Harbor knew how to run this machine, but operating it is a whole different story. It takes a lot of training to be a stacker/reclaimer operator, especially a good one.

|

| 1, cropped |

|

| 2 |

|

| Will Glick Sr. commented on Ryan's post |

|

| Will Glick Sr. commented on Ryan's post |

|

| Will Glick Sr. commented on Ryan's post Current view |

Ryan Boots posted five photos of #3 stacker/reclaimer

|

| Will Glick Sr. commented on Ryan's post [In addition to this photo of the bucket wheel missing, Will added several photos of a stacker that fell.] |

|

| Sean Howard posted Correction, the boat is 728' long. Ryan Hunt: Wow!! What made it collapse? Shaun Connelly: Ryan Hunt limit malfunction. Raised past limits and toppled over. Robert Hutchinson: Shaun Connelly I'm sure somewhere was a standard test. I remember in the 750 bldg Cleveland works before operating an overhead We/I would do a 3 step test raising the block into the limit switch from various distances at 3 different speeds (points). The last test is/was 5 point speed into the block....one time it did not stop and the block came crashing down...luckly, no one was hurt. Will Glick Sr.: Ryan Hunt stupidly, lack of maintenance and poor management . I was an electrician and worked on #4 stacker/reclaimer for 36 years before retiring. The official cause which is BS was electrical/ mechanical failure. Supposedly the boom went through the limits and didn’t stop which according to the video from the cameras on the stacker is definitely not true. James Ross: Will Glick Sr. The leg that supports the upper unit above the ring buckled. David Rodrigues: I was there working the night it collapsed...heard the whole thing on the mill radio and felt the ground shake twice when it went down.. Operator barely escaped with his life... James Ross: After this one fell, they had another 395 guy and I immediately rush over to the other stacker and pad weld all the feet to prevent it from happening again. [Some comments are about how the inspections are seldom and rushed. And the results are kept secret from the operators and maintainers. (I presume that was A/C. I wonder what C-C will do.) The boat was Joseph L. Block, built in 1976. There are more photos of mangled and bent steel that I did not bother to copy.] |

|

| Sean Howard commented on his post |

|

| Will Glick Sr. commented on Sean's post |

Michael Laskowsky posted 16 photos with the comment: "Can't believe it has been 10 years since this stacker folded itself in half before collapsing in a heap. Never a dull moment in Burns Harbor... Anyone know how long it took to clear the mess and get the new one up and running? I left shortly after this happened. Sure do miss the excitement some days though..."

Rob McKay: Damn I don't remember that, did they figure out the cause??

Michael Kane: Rob McKay they said limit switch failed.

Will Glick Sr.: Michael Kane I worked on this for over 30 years as an electrician. There were many thoughts on the cause but they were wrong. I knew this stacker very well both electrically and mechanically and I can say that it was definitely a mechanical malfunction. I won’t go into all the details, but I can disprove all of their guesses. There were problems with the boom at the pivot point area that were never resolved. Lucky the operator got off 2 minutes before it fell.

Michael Kane: Will Glick Sr. We were out there that night and for the next 2 years cleaning.

Chad Yester: I actually was one of the Ironworkers who demolished that wreck....the counterweight box girders was one Pic...over 400 tons...I got some awesome stories and great memories on that one!

Jeff Armfield: I work in BOF n only hired in back in 21, but I've been told the story of the stacker collapsing multiple times n every time I work service floor when I see that thing I just can't imagine it collapsing. I was told the "new" one came from Europe cause they didn't have one anywhere this side of the Atlantic they could get...idk if thats true or not

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

|

| 13 |

|

| 14 |

|

| 15 |

|

| 16 |

|

| John Smith posted Good morning from Burns Harbor Iron Producing. |

|

| Aaron Smith commented on John's post Good morning |

|

| Rich Jasper commented on John's post, cropped Cliffs Dearborn C Blast FCE. THE NEWEST in the CC organization [More comments indicate that it was commissioned in Oct 2007.] |

Allen Sydow posted four photos with the comment: "Burns Harbor Cleveland Cliffs."

Richard Allison: I have worked in over half the blast furnaces in the US in the 1970s and 1980s when there were over 125 blast furnaces running. In order were my favorites to work and the people that went with them. 1. USS-Fairfield Works No.8, 2. Republic-Gadsden Works No.2 3. Armco/AK-Ashland Works Amanda/Bellefonte Furnaces. 4. Empire-Detroit Steel Louise Blast Furnace 5. Bethlehem Steel-Sparrows Point L Blast Furnace.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Tim Timbo Shepard posted View from top of the coal silos in Burns Harbor Coke plant from about 6 yrs ago when owned by ArcelorMittal now Cleveland Cliffs. We went up here once a week to clean in coal handling, lots of stairs. Tyler Massengill: I'm up there a couple times a day to clean the tripper. Those stairs never get any easier. Scott Yuill: I remember back in the early 80’s, we had a large fire in the area of this picture just north of the coke ovens. We threw a lot of water for a long time. The unit was back up and running within a week. |

|

| Rick Boots posted #3 stacker at Cliffs Burns Harbor from 4 stacker. Note: 1 & 2 were never built. David Conkle: Ran both of these stacker reclaimers back in the mid 70s. Pain in the ass in the winter. You have to walk all the way to the cab. James Ross: I remember when this thing collapsed a few years back. They had another guy and I rush over to the other stacker to weld on gussets so it wouldn't happen to that one too. Chris Merry: Ryan Boots Burns harbor was supposed to be massive. It ended up 2 blast furnaces, 3 BOF pots, 2 casters 84", 160" and 100". Oh and two batteries. It was supposed to be a 4 furnaces, 4 batteries, beam mill, bar mill plus others. I read the old plans for this place it was supposed to be HUGe |

|

| Will Glick Sr. commented on Rick's post |

|

| Will Glick Sr. commented on Ryan's post [I presume this is #3 after the wheel fell off.] |

|

| Will Glick Sr. commented on Ryan's post This was when the old #4 stacker”tipped “ |

|

| Ed Bowmar posted No.1 caster.. Burns harbor Ed Ritter: This shot was taking from under the south strand starter bar rack... |

|

| Brandon Sims posted The mighty 80” hot strip mill slab yard. Cleveland-Cliffs East Chicago, IN. |

Some comments indicated that most of their slab storage is outside, so I looked for it. That storage is along a building starting from the lower-left corner of this excerpt. Before I found that, I found the coil storage lot that fills the right side of this excerpt.

|

| Satellite |

|

| Robert Meyer posted, cropped The Burns Harbor 80" Hot Strip Mill, (United), began operation in August of 1966. This picture's month is cropped but I'm confident that it is one of the first days of rolling. This mill is a "sister" mill to the 80" at Inland, built a year earlier. On occasion, parts were exchanged between the two mills. (Photo by Dave Mergl, from the Northwest Indiana Steel Heritage Project collection) |

|

| Robert Meyer posted This is the Dou Mill at Burns Harbor just before commissioning. It was used to temper tin plate product, called "twice reduced". Burns Harbor ceased tin plate production in 1983. Does anyone know if this line ran any product besides tin? Also, this mill was removed and became a Mechanical Shop across from single stand temper mill. Does anyone know the year it was removed? Trying to fill in some timeline gaps. TIA. (Dave Mergl photo, NISHP collection) Zygmunt Tesniarz: BLAW-KNOX STANDS Roland Parsons: Razor blade and banding stock One week a year for both Banding for entire corporation in the 80s Michael Starr: I was straight days fire watch for the entire dou mill tear down and remove , it was put in sea containers and sold to China |

|

| John Lethen posted My dad, Ted Lethen, was the Superintendent of the 80” Hot Strip Mill at Burns Harbor. He worked for Bethlehem Steel for 40 years. He started at Sparrows Point in 1958 and transferred to Burns Harbor after about five years. This picture shows the seven finishing mills. Jon Wolfe shared Chris Pitts: Those mills have had several upgrades over the years wow how stripped down they look in this shot. No HAGC or profile gauge. Jim Crownover: Familiar sight from 508 crane Andrew Jackson: Spent a few years in the 80” swapped many a roll packages. It’s pretty cool how it’s done. All hands on deck for a full general! Takes only several minutes to swap all 7 packages(if everything goes right). Finally installed walking beam furnaces few years back. Dave Silski: I was thinking the rolls were backwards, then I noticed the rotary roll positioner, very cool setup! |

|

| Brian Strong posted Iron treadwells at Burns Harbor last night [Oct 15, 2021]. [The comments discuss the various brands and nick names for these cars and offer some more photos including the bears treadwell. At Burns Harbor, they are called subs.] |

|

| Jon Wolfe posted MITTAL,BURNS HARBOR Greg Ostrozovich: Plate mill. Yuck. Place sucked to work at. [When challenged, he responded.] The schedule was horrible. Forced overtime. Scheduled 6 and 7 days a week. Many times, forced to work 16 hour shifts due to call offs because of the insane schedule. "Days off" were 24 hours one week, 23 hours the next week and your "long weekend" was 48 hours. Many weeks were scheduled 72-84 hours. Management was terrible. Complete refusal to change the schedule or follow any rules, including on the scheduling, seniority and job placement and even safety, unless fought with and forced to do so. Management running production jobs (an absolute no no) on calloffs. And a good old boys club of both management and older union workers that took absolute advantage of new hires who didn't know any better, including pawning off their job responsibilities on new hires with impunity. That's a start. Jeff Roush: Walking beam or pusher type? Sean Campbell: Jeff Roush This is our 110 mill, it's a walking beam furnace. Our 160 mill is still a pusher for now, though. Emilio Diaz: Inland had this kind of furnace and trsnsfer tables from the 2A Bloomer to the 28" mill. It was mighty cold on your back side and roasting on the front side as we were changing table rolls on New Years Eve 1978 🥶🥵 |

|

| Matthew Kawiecki posted World's largest plate leveler. 8500 tons of force with 5-9 roll retract. Matthew Kawiecki: Cleveland Cliffs burns harbor 160 plate mill Heat Treat line. Made by steel plantech. Discrete plate. Leveling range is .312"-4" and up to 180 KSI. Robby Lett: Who makes it Stamco, Herr-Voss, Delta? Those three are the only ones I'm familiar with. Matthew Kawiecki: Robby Lett Steel Plantech. |

|

| Kirk Martinsen posted Burns Harbor, Indiana about 2014 Karrie Frye: #2 ROLL SHOP... Lewis Graff: 72" swing hydrodynamic grinder with machine serial number 64A1390, if I remember correctly. Built in 1964 in Ansonia, Connecticut. Was the second machine installed at Burns Harbor in 1965 by the Farrel Corporation. The upgrade by Pomini in 2015 was my first Capitol Project and included an inertia block up rebuild of the machine. Prior to the rebuild, the machine was nearly 100% original mechanically and still ran on the old GE Mark Century 100s numerical control with an 8 bit tape reader. That machine was my baby, hopefully Burt is taking care of her! Lol. Robert Meyer: Lewis Graff 160" Plate Mill was running in 1964, and the sheet mill was operating in 1965, so it was probably the second machine installed in the #2 Roll Shop. An identical machine was probably running in the #1 Roll Shop. I'm not sure of your source for installation dates. I too was heavily involved in it's rebuild. We were a good team Lew! Mike Keen: Which department? Plate? Kirk Martinsen: Mike Keen I think this roll shop does plate and HSM. [HSM = Hot Sheet Metal, I believe.] |

|

| Burt Bearickx commented on Kirk's post Same grinder after the upgrade in 2016. |

|

| Kirk commented on his post |

|

| Josh Whitson posted John Slowikowski: Three steel mills in one shot. Midwest steel, the Russians at NLMK and the former Bethlehem plant. Mark Goodrich: Photo should be from mid to late 90's. Degasser is built and there is still some mold activity. Bret Yelachich: This is awesome, you can see the old ore unloaders, and the old 4 stacker before it collapsed. Will Glick Sr.: Stewart J Cort in the harbor, Old #1. Ryan Babjak: Late 90’s is the last time I saw a ingot out there. Robert Savage: Caster there finished in 86ish . Degasser there finished in 90ish . Soaking pits closed in 92ish . I'd say 91. Ryan Boots: Late 80’s early 90’s no coal injection in this picture. [See Mark's comment below.] [The four white tanks near the center are part of the Cargill Grain Elevator.] |

|

| Mark Goodrich commented on Ryan's comment coal injection is there in photo |

|

| Will glick Sr. commented on Josh' post MV Burns Harbor at the dock, North and South Unloaders and # 3 stacker in the background. Internet find taken from the Port of Indiana. |

|

| Comments on Josh's post |

|

| Bob Byerman posted Burns Harbor Construction. [These would be the hot stoves used to preheat the air that provides the blast of air for a blast furnace.] Will Glick Sr.: #2 stove looks crooked. Lol |

|

| Bob Byerman posted Burns Harbor 1971 Mark Goodrich: Koppers was the furnace contractor. Mark Goodrich: Powerhouse construction going on in the background. Steven Booth: Hard to tell if this is Charlie or Doggie. Edward Fanello: Steven Booth Charlie furnace based on placement of blast furnace and coke oven gas mains in the highline to the right of blast furnace being built. Will Glick Sr.: Edward Fanello D furnace was there in August of 1970 when I hired in. C furnace was under construction. Bob Byerman: In the lower right hand corner of the title block there’s a contract number of 2402 that’s the contract with koppers in Bethlehem all the drawings related to see furnace have that number in the drawing number from koppers. Viktor Mácha Almost the same viewpoint from 2015 James Torgeson: Mark Goodrich BH started processing slabs in 1964 that were railed in by the New York Central from Lackawanna. Dennis Davaney: Matt Barnard When Plant Broke Ground? Dennis DeBruler Dennis Davaney I assume the 1962 announcement included a ground breaking ceremony. Bethlehem considered building a steel operation in Northwest Indiana in 1906 in Lake County and in the 1920s in Porter County, but the costs were deemed to be too high. (I recognize the 1906 date as when US Steel built the Gary Works.) "In 1956, Bethlehem Steel decided to move forward with construction plans. They formed a subsidiary to quietly purchase land in Porter County near Lake Michigan. The Lake Shore Development Corporation eventually purchased over 3,000 acres of land. In 1962, the company announced its plans to build a finishing mill on the site. The Burns Harbor Finishing Mill commenced operations in 1964." The Federal government created the Port of Indiana in 1965 and shortly thereafter Bethlehem added a Primary Production Facility (PPF) at this location. Calvin Dorward: That has to be Charlie. Doggie in was started up Dec. 69. I was there for the build of D fce. Till 1990 when I retired |

Bob Byerman posted three photos with the comment: "Charlie furnace under construction at BH For Bethlehem steel."

|

| 1 |

|

| 2 |

|

| 3 |

|

| Robert Meyer posted Burns Harbor D Furnace build. Can someone tell me the proper name for this type of crane? C Furnace used a crawler BTW. (NISHP collection) Mike Vannatta: “Guy” Derrick, note the Guy lines - not legs and definitely not a dtiff leg Derrick, all your old Bridgeman will be familiar with this , my Dad helped build “D” furnace at Burns Harbor along with Steve Depung, and many other great Ironworkers from the region and lots of “Boomers “ ! Thanks for posting Bob !! It was a privilege growing up with you in Burns Harbor you and I know every neck of the woods around that place !! Lol |

|

| Roy Conrad commented on Robert's post It’s a guy derrik. |

|

| Roy Conrad commented on Robert's post For a little extra razzle-dazzle, the top paragraph is a description. |

|

| Robert commented on his post Here is C Furnace. Crawler crane on this job. (Dave Mergl photographer, NISHP collection) |

|

| Tom Cera posted Cleveland Cliffs Burns Harbor Coke flare stack this frigid morning. [I was glad to learn from the comments that the orange column is a "light pillar" instead of flame. Although the yellow at the bottom looks like a pretty big flame. A light pillar is the light reflecting off of ice crystals in the air. Note the "frigid morning."] |

|

| Will Glick Sr. commented on a post Sintering Plant at Burns Harbor ( Google Earth). 1 strand I believe 16 feet wide. Capacity was originally 5000 tons per day. With a few alterations I believe a record was set 9,200 if I remember correctly. The induced draft for the Sintering process was done by two General Electric 9000 horsepower Synchronous motors. |

|

| Allen Clark posted, cropped Cleveland Cliffs, Burns Harbor Steel Mill. Burns Harbor, Indiana. |

Ryan Boots posted two photos with the comment: "Cold February night at Cliffs Burns Harbor."

|

| 1 |

|

| 2 |

|

| Mike Thornton posted No.2 CASTER RUNOUT BETHLEHEM STEEL [Bethlehem had a lot of plants. Judging from some comments, this was the Burns Harbor plant.] Lance Beauparlant: Start of cast just disconnected Walt E Fles: I worked there in the summer of 1986 in the #2 caster office as a summer engineer doing programming. I remember hearing a loud boom and asked what it was, and a foreman said they probably dropped the ladle on the turret a bit hard. Then another time I heard a loud boom and I said, "turret?" Then they looked outside to the caster floor and they yelled, "no, stay put!" Turns out there was a breakout in the intermediate floor. The next day they showed me what happened and little shards of steel were stuck everywhere. I guess #2 caster had a lot of issues with mold taper until Voust-Alpine got it straightened out. Wayne Ellis: I ran Charlie strand cutting torch..Our biggest slab was 48 inches wide and 396 inches long after being cut. Jeff Roush: Wayne Ellis at WP widest slab was 70 inches and longest was 360 inches….2 strand wide slab caster. Wayne Ellis: 70 inches is a wide slab. Scott Cuma: Wayne Ellis we run up to 75 inches on both strands. Jeff Stalbaum: Scott Cuma but remember we are capable of 86” wide X 420”. Scott Cuma: Jeff Stalbaum I don't want to see that lol |

|

| Robert Meyer posted One of my favorite Mesta themed photos. Delivery of Mill post, 50" X 96" Slab Mill Burns Harbor. Photo in 1968. Burns Harbor's Slab mill began operation on October 20, 1969. [Additional comments explain this slabbing mill was closed after both of the continuous casters were working.] Robert Meyer posted again James Zmuda: Mesta had a universal bottom for their mill stands that they use to use . The slabbing stands may have been larger. Blaw Know would have cast a heavier stand. Doug Majka: Is a mill post the same as a stand? R Jim Echlin: Doug Majka Actually it appears to be a mill housing. A stand is comprised of two housings mounted on a shoe plate, etc. I’ve not heard of it referred to as a mill post. Josephine Lily Brown posted One of my favorite Mesta themed photos. Delivery of Mill post, 50" X 96" Slab Mill Burns Harbor!! Milko Kašić: What was the purpose of this mill in the slab mill? Or was it just passing thru there on its way to the hot strip mill or the plate mill? |

|

| David Mikail posted ArcelorMittal Burns Harbor, heavy plate mill | Viktor Mácha - industrial photography |

|

| Robert Meyer posted Burns Harbor's 50" X 96" Universal Slab Mill in operation. (Dave Mergl photo, NISHP collection) Pat McCon: Fun to be in the pulpit of a slabbing or blooming mill, watching all arms and legs being used to manipulate the ingot! Graham Whitfield: Pat McCon You said it Pat, The Mill Pulpit, what a place. Our Rollerman ( Mill Operator) operated the Screwdown, the Manipulators and finger tilts, Edger Mill, by both hands. Foot pedals operated the Roller tables. Two ingots were Rolled simultaneously, known as Tandem Rolling. It was ‘Poetry in Motion’ and 500 tons per hour was the norm. Long time ago but great times. |

|

| Robert Meyer commented on his post Burns Harbor Slab Mill. Dated 12/3/1969. Day one? (Dave Mergl photo, NISHP collection) |

|

| James Gourley posted Hired in 1966 at Bethlehem Steel (Burns Harbor Plant) as a CA Line Tractor Operator. [There are several comments from people who also drove one. The biggest weight I saw was 70,000 pounds.] |

Can anybody help with the history of the stacker-reclaimer machines. Looking to find out who supplied them in what year etc. Thanks in advance

ReplyDelete