|

| http://www.barnshaws.com/structural-tees.php |

This reminded me of the first annual EMD plant tour that I took many years ago in La Grange, IL. (Actually, the plant is in McCook, IL, but uses a LaGrange postal address.) Since the tour was part of an anniversary celebration and the plant was built in 1935, it was probably the 50th anniversary in 1985. At the time, EMD was the Electro-Motive Division of General Motors. Now EMD stands for Electro-Motivie Diesel. I'm really glad I took the tour because the "annual" part never happened. I did not notice any tours after that one. And the plant quit assembling locomotives in 1991 when GM used just their assembly plant in London, Ontario, that was opened in 1950. The headquarters, engineering, training, and parts (engines, generators, alternators, etc.) manufacturing remained in La Grange, IL. Progress Rail Services Corporation, a wholly-owned subsidiary of Caterpillar, bought EMD August 2, 2010, as a wholly-owned subsidiary. A new assembly plant was opened in Muncie, Indiana, in 2011, and the London plant was closed in 2012 because of union labor issues. (EMD24B is a Tier 4 rebuild of a GP40.)

|

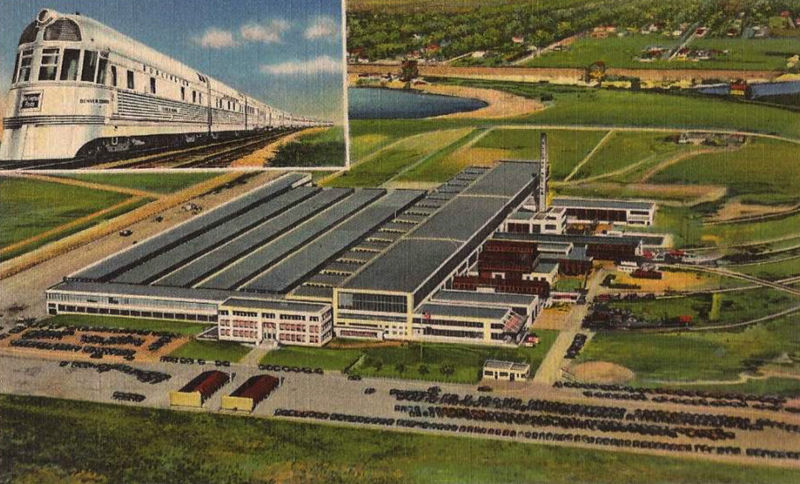

| La Grange, IL, Plant, late 1930s |

(Update: Lost Illinois Manufacturing posting has more pictures and information about the plant.)

|

| safe_image for Terry Spirek Flickr They had there own Fire department and a coal fire electrical plant. They would get coal delivered by train cars. They had a crane that would lift the coal car off the tracks then turn it upside down to empty it, a large hammer would bang the side of the car to get all the coal out of the car! The Mechanical contracting company I worked for got the contract to do co-generation with their own diesel engines to produce electricity when they removed the coal plant. We continued to do the work as they reduce the plant sight as they sold off parcels! In the upper left side of this photo are the parking lots. When we 1st got the job sitting in the guard shack filling out paper work to get a badge to do surveying there was a picture of these parking lots filled with old model t fords hundreds of them. FYI the site was chosen because the bedrock level was 0'' on the majority of the site. There is a quarry just on the other side of Roosevelt rd. near by. |

|

| Illinois Central Railroad Scrapbook And Occasionally Other Railroads posted In 1937 the Chicago Rock Island & Pacific Railroad (the "Rock Island") began operating streamlined passenger trains on select routes. To power these trains the Rock Island bought six TA locomotives (numbered 601-606) from the Electro Motive Company. This photo shows four of these locomotives under construction at the EMC plant in La Grange, IL. This photo provides a nice view of the framework within the locomotive. At first glance the locomotives might look like an F-unit, but there were several key differences. First, the TA's were powered by a Winton engine (the "T" in TA stood for 1,200 horsepower). Second the locomotives rode not on Blomberg trucks, but rather on unique trucks more similar to the AAR Type B trucks. The locomotives saw service across the RI system, including trains into Memphis. They were withdrawn from service in the late 1950's and scrapped. EMD builder's photo, Cliff Downey coll. |

The assembly of a locomotive started with a slab of steel the length and width of the locomotive and about 4 inches thick. The bottom part of the slab in this Metra locomotive has the white stripe that is just below the side panels.

|

| 20140530 0008 |

The tour guide then showed us two T-sections that had been created by cutting an I-section down the middle with a cutting torch. He explained that the T-sections were bent because of the release of stress. I remember that one end was about 6 inches from where it would be if the beam was straight. However, EMD did not straighten the beams as was mentioned in the above video. Instead, they welded the bent beams to the foundation slab and that caused the slab to bend slightly. The tour guide explained that when the locomotive is built and the engine and other heavy components are installed, the weight would bend the slab down so that it would then be straight again.

I'm surprised that an I-beam has so much internal stress to cause the T-beams to bend when it is released. Every picture I have seen of a rolling mill looks like it is hot rolling the beams. In fact, they talk about soaking furnaces that reheat the metal blooms to 1200 degrees Centigrade for rolling. I would think that if the metal was hot, it would be malleable enough that stresses would not build up during the rolling. It seems that some of the beam's strength would be wasted to resist these internal stresses.

|

| Joshua Lemier posted |

|

| Electro-Motive Builder Photos posted 1949 (?) Frame milling machine (?) Karl Schaefer: Yes it milled the pads and was lifted up by an overhead crane from station to station. It’s enormous weight flattened out the locomotive under frame’s built-in camber. It was in use well into the 1980’s at the LaGrange plant. A one of a kind! Patrick Carroll: It’s an ingersoll gantry mill. Looks like it’s portable. David Semple: Michael Schwiebert Used to mill the pads for the engine, generator and air compressor. James Torgeson shared Big machine tools are currently of interest in the group (Mesta, Blaw-Knox, etc.) so I thought this giant portable milling machine at the Electro-Motive Division of General Motors would fit right in! Real Bubba: Appears to be milling engine mount pads to prevent block twist? James Torgeson: Real Bubba I believe so, as those were critical. |

|

| Andy Burns commented on the EMD Builder Photos post Sitting on a flat car to the rear of the property at La Grange. |

|

| LIVE GAME CS posted Brand new Union Pacific EMD SD60M Nos. 6194 and 6205 are in the final stages of assembly as they are “trucked” with an overhead crane specially for visitors during an open house at the sprawling EMD plant at La Grange, Illinois, on September 17th, 1989. Photo Credit to Mike Danneman. |

As long as i am feeling nostalgic I might as well throw in how I miss the original and fully functional Electro Motive Plant in LaGrange and all those beautiful Diesels it turned out! Lower left: The body of the first E unit for the Baltimore and Ohio. Middle: Construction of SW's and E's, Lower right, construction of F units.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Glen Miller posted Photo of new ATSF EMD F3 locomotives 16, 17, 18 and 19 at the EMD plant in LaGrange, IL in 03-17-1948. History's Mirror posted New ATSF EMD F3 locomotives at the EMD plant in La Grange, IL, 1948. Larry Johnson shared New Santa Fe Railway Warbonnets at the EMD Plant in La Grange, 1948. ‘All the Way’ Pete Maley: At the height EMD cranked out 5/day. Now they might do 1.2/week out of the Muncie and Mexico plants. Muncie was also refurbishing a lot of the older models. |

|

| Chicago & North Western Historical Society posted Here is an interesting and unusual view of an E-7A #5012B. The back of the Ken Zurn photo says that the locomotive has been "stripped for shopping" in Chicago." The date is September 1966. this photo and hundreds of other Ken Zurn photos and negatives are held at the archives of the C&NW Historical Society. Can we help you? [Before they learned how to build big "road units" with a frame using a thick slab of steel reinforced with a couple of T-sections, they used truss-bridge technology in the sides of the cab.] |

|

| Dan Deyoung posted Ok here goes most people don't know diesel engines in trains are the original HYBRIDS FROM THE START GM General motors EMD Electro motive Division had the technology to turn gas or diesel in to Hybrid Cars from the 40s 50s and 60s So where were they? Diesel engines, generator and traction motors Only for railroads not us |

|

| GMPhotoStore posted As we can see in this photo from GM’s ElectroMotive Division building a locomotive requires a unique kind of body shop. Mike Schwartz: The first two front ends could have been pre-production pilot models that are being refurbished for sale. Bill Osgood: Mike Schwartz that man makes sense. They look like they are being refurbished rather than constructed. It seemed strange that the glass and trim, like the wipers and grab irons, would be fitted before the body is finished. Bill Means: Worked at GE in Erie Pa for 20+ years. We put EMD out of business by using DC motors and computers to make our locomotives 50 times more fuel efficient. GM’s car business was going down so we passed them up standing still. Michael V. Witham: GM sold EMD to a private equity group in 2005. It was sold in 2010 to Caterpillars Progress Rail. Wayne Brunzski: Was this 103 rd st Chgo 🤔🤔🤔 before LaGrange. William Huber: Back when lead was used a body filler. [There are some comments about passing Tier 4 emissions regulations. This one caught my eye: Brad Rice: Cat had to get out of supplying engines for Trucks. Could not pass emissions.] Kevin Murray: I made piston cooling tubes and electrical connectors for them for over 25 years. Great people and a great company, but GM corporate gutted resources and left them under capitalized and under-resourced. The SD70MAC was a great locomotive, but the 710 engine could never pass Tier 4… it’s compliant replacement (the H engine,) a 4-stroke, cast crankcase, suffered a lot of problems until being abandoned and sold to China. GM tried to sell to Caterpillar around 1991, but the UAW wouldn’t permit the sale owing to long-standing issues with Peoria. Mateusz Ruszel: Caterpillar is in the process of gutting pretty much everything at McCook plant except design, some engineering & administration. Don Gerdts shared |

Greg Burnet shared six photos with the comment: "Electro-Motive plant construction pics from the 1930s."

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 Contruction Photo by Kaufmann-Fabry Negative Number (35)-27 Electro-Motive Builder's Photo https://www.facebook.com/photo.php?fbid=10158413806313658&set=g.196767310439590&type=1&theater&ifg=1 Greg Johnston Date? Electro-Motive Builder's Photo according to the bottom left negative number; 1935 and the 27th photo in EMC negative file. |

|

| 5 Reception Room to General Manager (1936) Negative Number 36-0202 |

|

| 6 |

|

| 1 |

|

| 2 |

|

| 3 |

|

| Kevin Piper posted Something you don't see anymore. An EMD test train heads south at Symerton, IL, on the old Wabash. The train has SD60 3, an EMD test car, a SDP40F, and a SD45X. Today the line is gone and so is GM ownership of EMD. 4-12-89 Brian R Bundy I worked this train several days while we had it in Decatur. We made a couple trips between Bement and Gibson City daily before returning to Decatur. They were testing out making transition on the EMD 3 for the SD70 model. EMD 3 did the work in power while the other two locos were in dynamic brake to simulate a train, all controlled by the engineers in the test coach. Brian R Bundy I saw EMD 3 several years later at the TRRA yard in East STL. It had the standard truck on one end and the radial truck on the other. Kevin Piper I ran the EMD 3 on BNSF. It had two radial trucks by then. |

Steven J. Brown posted three photos with the comment: "EMD celebrated the fiftieth anniversary of the FT with an open house at the factory in LaGrange (McCook), Illinois - September 17, 1989. They assembled a colorful group of their products!"

|

| 1 |

|

| 2 Steven J. Brown posted EMD celebrated the fiftieth anniversary of the FT with an open house at the factory in LaGrange (McCook), Illinois - September 17, 1989. |

|

| 3 |

|

| Doug Kydd commented on Steve's reposting of his second photo above. I was there that day too. Will remember it for a lifetime! |

|

| Noah Haggerty posted Thirty-six years ago today on September 17, 1989, Electro-Motive Division opened its doors for the 50th anniversary of the famed F-unit locomotive at their shops in La Grange, Illinois. Many railroads from across the country were present for the event en masse. Notably for the Illinois Railway Museum, Santa Fe FP45 #101 later went to the museum as #92. Chicago & Northwestern GP7 #1518 is also in the background. John & Roger Kujawa Photo, Thomas Dyrek Collection. |

|

| Thomas Bowers posted EMD 50th Open House LaGrange, Il. Fall of 1989 Alex Lorenz Very nice, is that 268 one of those SDP40F? Steven J. Brown Yes - it was used as a test bed for AC traction motors. Built as Amtrak 531. |

Jerry Coleman Yes, LaGrange I believe that "new" facility opened in the late 40's these drawings are part of a promotional piece Wm. A. Hottinger produced for Electromotive while on staff as their Illustrator. The family has several others as well from the promotional book.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| Steven J. Brown posted A long line of new Conrail SD40-2's and GP38-2's await delivery along the back fence at the LaGrange EMD factory in McCook, Illinois - July 2, 1978. |

Gabriel Eduardo I hope to see other railroads besides UP buying those locomotives.

Dennis DeBruler I thought EMD (actually Cat's Progress Rail) moved locomotive assembly to Muncie, IN. So why are there locomotives setting at the original EMD plant?

Vincent Gortner Engineering staff is still there, I believe.

Marcelo Menendez yes,

Jeff LewisJeff and 1 other manage the membership, moderators, settings, and posts for Chicagoland Railfan. [Evidently you can get this view from Fed Ex] https://www.google.com/.../@41.7950353,-87.../data=!3m1!1e3

|

| 1 |

|

| 2 |

|

| Ken Schmidt posted

September 17th, 1989, EMD opened it's doors to the public. They had assembled quite a collection of units from all ages. Here is one view of that display in LaGrange.

Not sure if EMD did this again in it's history.

|

Richard Stewart shared 8 photos from an EMD Assembly Album.

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 Mark Hershoren shared, brighter exposure Charles Smith: Lot of puddy to get the noses smooth..Photo taken at EMD la Grange plant. Must be one of the last F or E series of units on order. Rich Kranz: Charles Smith That’s not putty, that’s lead. Paloma Tomas: That plant use to go 3 shifts and weekends , and now ...[nothing] Jr Luciano: Love this ❤️ Two favorite EMD'S, F-Units & GP7/9's. Tim Hayes: Look at all the filler needed to make the curves fair. This is one reason that this body style was abandoned in favor of ones with straighter lines. David Jansson: Shows how EMD created the compound curves on the nose. BEND AND HAMMER STEEL, APPLY BONDO!!!! Richard Jahn: David Jansson - Having worked on several EMD cabs they did not use "bondo" All metal sheets were "leaded" at the joints. George Keller: When we updated the Wabash F-7 at the Mad River and NKP Railroad Museum we had to do quite a bit of work on the nose of the engine. The nose was full of lead that was used to contour the shape of the engine's nose. John Vincent: George Keller Lead was a normal body filler in those days. You'll find cars up to the end of the 1960's with lead in the for body filler. Jeffrey Cwan: I once heard no two noses were exactly the same. Richard Jahn: Jeffrey Cwan - incorrect. Nose is made of several different sheets of preformed metal attach to a frame leaded together at the joints. All of the sheets and frame members were standard parts which could be ordered from the EMD parts catalog number 90 in case repairs were needed. David P. Reaves III: Budd Co. shot-welding formed stainless steel sheets for passenger car construction was equally interesting. The welds were never perfect, and they bought -and used- putty by the barrel. |

|

| 8 |

|

| 1 |

|

| 2 |

|

| 3 |

|

| 4 |

|

| 5 |

|

| 6 |

|

| 7 |

|

| 8 |

|

| 9 |

|

| 10 |

|

| 11 |

|

| 12 |

Two photos from a Parts Album show a couple of generations of a cylinder boring machines.

|

| a |

|

| b |

|

| Cliff Downey posted In the summer of 1963 a new DD35 diesel-electric locomotive is lowered onto its trucks at the EMD* plant in La Grange, IL. The DD35 was built in response to Union Pacific's request for more powerful locomotives than the 2,500 horsepower locomotives available at the time. EMD took up the challenge and designed the DD35, which essentially was the machinery of two GP35's locomotive (a single GP35 packed 2,500 horsepower) placed onto a massive 88' long frame. The locomotive rode on two four-axle trucks, the largest ever used (up to that time) to construct a diesel-electric locomotive. The DD35 did not have a cab, for it was intended to be coupled with other locomotives when in service. The first two DD35's were built as EMD demonstrators, and were numbered EMD 5653 and 5655 (the locomotive seen in this photo is one of these two locomotives, but it is unknown which one). These two locomotives, sandwiched between a pair of GP35's, tested on several railroads. In May, 1964, the Union Pacific bought the two GP35 and two DD35 demonstrators. UP then bought 25 more DD35's plus 15 DD35A's (which were equipped with cabs). Southern Pacific also bought three DD35's, but no other railroads bought DD35's or DD35A's. EMD photo, Cliff Downey collection. *Electro-Motive Division, General Motors |

Is EMD's new Tier 4 a bust? Some of the more meaningful comments on a posting.Christopher Overbeck Union pacific has stored all the new tier 4 sd 70 aces.

Will Daniel Martin Christopher Overbeck because progress rail wont release the tooling or repair documents and schematics.

Ben Schneider Yea because they are plies. They suck. Emd never should have had cat put a 4 stroke tier 4 in their units.

Christopher Overbeck Ben Schneider its not an engine problem. Its electrical issues. Over half wont start because of inverter failure.

Ben Schneider Yea well I'm a machinist and that engine is so dumb to work on. We had a unit with 15k miles and it blew out 2 power assemblies.

Christopher Overbeck We had the test units for the Sierra's and we burnt 1 down.

Jesse Rooker It's a shame, because for train crews, they are the quietest and smoothest out there. Hope they get the issues fixed.

Christopher Overbeck Jesse Rooker they are not even looking for the solution right now. Its not part of the unified plan.

[I wonder what the "unified plan" is.]

Christopher Overbeck Sam Fuller we started putting them in storage up in roseville because of electrical isssues. Probably stored 25 of the 100 already.

Will Daniel Martin Christopher Overbeck we've put at least 10 in storage in NLR for the same reason we're told they're going back to progress [Progress Rail].

Leon Shahayda The ones I ran were bad to wheelslip on wet rail.

Billy Sullivan Way back....my brother and I went to rescue a 15,000 ton rock train from the BNSF....the crew left this train tied down on the side of Dobbin Hill..( you need to be at 1.1 HPPT to pull the hill....4 SD 40's pulled this train from a dead stop 1.5 miles to Crest the hill....no double over...Those punk 70 aces would have never made it....js

[Several comments indicate that EMD can't figure out how to make a decent toliet and the cabs always smell.]

Chris Madera AIr conditioner inlet is next to the potty. These units are strong but smelly work horses.

Mike Huhn NS ones, when there aren’t any issues with them, run like champs. Quiet and are great on heavy trains.

Brian Richardson Mike Huhn I like them better than the 2600-2700 dc series... but I still like the es44ac engines best.

[Evidently a computer stops the engine rather than let it idle. But then the inverter fails and the engine won't restart.]

Comments on a posting:

Jed Boyles What happened? Does GE build all new locomotives now? Someone please help me with some information..

TJ Cloke Muncie, IN is where EMD - Progress Rail - Caterpillar built a new assembly plant. The tier 4 SD70ACe has been plagued by reliability issues (most seem to be fixed), which turned away large orders except UP who ordered 100 units. Currently BNSF, CSX, and NS have orders for 10 units.

NS is getting 40 credit SD70ACe's along with their 10 tier 4s however.

| ||

| EMD posted As we can see here, worker are smoothing the seams as the Geep hoods moves along at West Pullman, Ill. Electro-Motive Builder's Photo The Geep was probably trucked to plant 3 in Cleveland for final assembly. The F/E nose goes to plant 1 in LaGrange. This is at the former Pullman plant. Dennis A. Livesey At first glance, they looked like screens on the loco side. Looking closer, those are large reflecting surfaces for making, bright, even light so the grinders can see their work accurately, IMHO. (I am not a sheet metal worker so I am guessing.) Greg Burnet shared William H. Tolliver EMD facility was East of Cottage Grove on 103rd st. Locomotive subassemblies. Pullman plant was on 111th st. And Cottage grove. Dave Ladislas Sr. William H. Tolliver,correct.The EMD shop at 103rd. was a former Pullman shop way back in the day.Pullman Shops went from like 103rd. on the N. to almost 115th. on the S.,including their Calumet Shops. Dave Ladislas Sr. Mike Rusnak,when I was working at Pullman we had a lot of welders that also worked at 103rd. st.Welding 16 hrs. a day had to be brutal. Ean Kahn-Treras Oh very neat! Had no idea this was down here. Must’ve kept the N&W quite busy. Were they the main carrier providing service along the Pullman Connecting Railroad, or was it a big joint venture? [Unfortunately, as of 23 hours later there was no answer.] EMD posted Recent Photo released by Progress Rail at Plant number 2. Cabs as far as the eye can see. Greg Burnet shared | Ed Elm: Bob Lalich when I worked there they did not assemble cabs any more we made crankcases, fuel tanks ,traction motor housings, fan frames ,and plow blades and many other smaller parts. Bob Lalich: Ed Elm - I grew up near this plant. Until I saw this photo several years ago, I thought that Plant 2 made parts such as you describe. This photo was quite a surprise to me. I wonder how the cabs were transported to LaGrange? Steven Marcyk: Geep cab being worked on is IC 8901 delivered May '51. The order, 5171-1 is written several places on it. 1951 would make everything in the photo a 7....F7, FP7, or GP7. [Some comments indicate that the US government took it over during the war to make airplane wings.] |

|

| EMD posted Jerry Jewels: What's with the cowl on the Right? What road is that? Electro-Motive Builder Photos: Jerry Jewels test bed for prime mover used in marine, drilling rigs and peaker application. Michael Riha shared Rick La Fever: Plus the White Elephant Electric Locomotive. Too bad that didn't work out. Things might be different today on railroad tracks. |

|

| Henry Goodbread commented on EMD's post https://flic.kr/p/ATtE9M [This is a closeup of the prime mover testbed dicsussed in the comments above.] |

|

| EMD posted GP18 1960 Gregg Wolfersheim: 6 cylinder water cooled air compressors. |

|

| EMD posted Date 1975 EMD Negative Number 75-1108 Ed Cooper: The Alaska RR and the B&O received GP40-2s that year. |

|

| EMD posted Road: Union Pacific Model SD60 Date Jan 1988 EMD Negative Number 88-0022 |

|

| Michael Matalis posted EMD open house in 1978. I never knew that Electro-Motive built Daleks!!!!!! |

|

| Marty Bernard posted Inside the EMD Erecting Shop at McCook, IL on June 10, 1978. This unit was probably about to be a GP40X. |

History of EMD 657 and 710.

EMD started production in a Pullman building before they got their La Grange plant up to speed.

EMD could end engine production at LaGrange (source) 600 jobs building engines would be lost to North Carolina and outsourcing. 600 keyboard pounding jobs (engineering, administration and support operations) would still be left.

Micahel Matalis posted a link to his Flickr album of outside shots with the comment: "Photos inside the EMD plant taken during their open house in 1978. There are a lot of photos in this set, but they are of a subject that we do not often get a chance to see:"

Micahel Matalis posted a link to his Flickr album of inside shots with the comment:

Michael Matalis I'd heard that photos had been banned because of a new process of laser hardening of pistons or piston crowns.

Looking through Michael's Flickr albums, I found his outside and inside albums.

(new window)

(new window, it has extensive comments)

(new window)

|

| Facebook Reel |

This is awesome! My family worked at McCook over decades starting in the late sixties. It was so cool to see the open day. I was 12 and there! Thanks for this!

ReplyDeleteThe best was there Christmas Parties at the plant for the workers familys. What happened to the huge model trainset they had inside.

DeleteThe new Santa Fe F3s were built in October/November 1946. You can see National of Mexico F2s in the background which were shipped the same month. The photo dates to early November 1946, not March 17, 1948. Ed in Kentucky

ReplyDelete