Any big bulk-carrier boat that you look at today on the Great Lakes will have a conveyor boom near the bridge to unload its cargo. (Some freighters have the boom at the bow instead of the stern.)

|

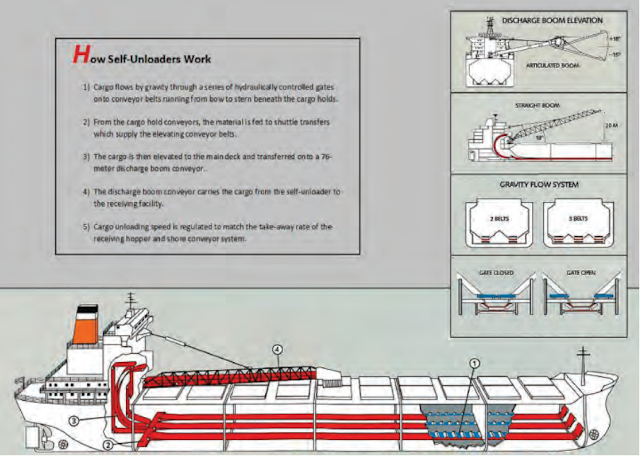

| AmericanSteamship The graphic above demonstrates a self-unloader in action. The cargo is unloaded using a system of conveyors built into the ship. The cargo holds are "hopper-sloped", or slanted on their sides, so that the cargo will flow down through gates located at the bottom of the holds. The cargo drops onto a tunnel conveyor belt, which carries the cargo to one end of the ship and transfers it onto a loop or incline conveyor belt system. This system carries the cargo up to the main deck of the ship where it is then transferred onto the boom conveyor belt. The boom conveyor can be lifted and swung hydraulically left or right to position the cargo on the dock or into a receiving hopper as specifically desired by our customer. |

|

| jenish, p18 |

|

| jenish, p53 |

|

| CSLships |

|

| Troy Greatens commented on Ben Ziemendorf's post |

|

| David B Seehafer commented on Ben Ziemendorf's post |

Here is a different view of the boom.

|

| Michael Eskelin posted Burns Harbor, back in the saddle again. |

|

| Andrew Dean Detroit posted Take a load off - Dorothy Ann unloading on the Rouge River. |

(new window)

An early example of a self-unloading ship.

|

| Photo from LC-USF33-016147-M3 from LOT 1073, Jul 1941 Drawbridge, Chicago, Illinois |

|

| Philip Wizenick provided a better exposure in a comment on a post |

|

| One of ten photos posted by Brian Wroblewski Here’s H. Lee White on her first grain run to Buffalo & the first new grain boat for the Frontier Elevator in about 10 years. 250’ boom. [Fontier Elevator is part of the General Mills cereal plant.] |

CSLships has a video that provides more detail as to how the self-unloaders work. Their video describe a C-Loop conveyor that lifts the material to the deck. This is different than the inclined conveyors that American Steamship describes. The boom can typically be raised 18 degrees, and it can swing 90 degrees to either side.

When I saw the white piles in the photo below, I wondered if it was salt or limestone for a construction project. They were obviously made by a self-unloader from a boat on the Chicago River. But then the age of this photo (older than 1987) made me wonder when self-unloader technology was developed. Since the last bulk carrier built without a self-unloader (Edward L. Ryerson) was built in 1959, the technology would have been available to build those piles.

|

| Chicago History posted |

|

| 3D Satellite |

The J. F. SCHOELLKOPF JR. is seen in this fine picture taken on June 9, 1960 in the St. Clair River by historian and photographer, Peter J. Van der Linden. It was built in 1907 as the straight deck bulk freighter, HUGH KENNEDY for the Buffalo Steamship Company, managed by the John Mitchell shipping fleet. American Shipbuilding constructed this 557 foot boat at its yard in Lorain, Ohio.

In 1922 the Mitchell shipping interests sold this and other ships, with the American Steamship Co., Boland & Cornelius, purchasing it. In 1930 it was renamed with its only other name, J. F. SCHOELLKOPF JR. In 1933 it was converted to a self-unloader, likely giving workers at the American Shipbuilding yard in Lorain much needed employment during the Great Depression.

Over the years the SCHOELLKOPF would get improvements, including repowering in 1950, but remaining as a coal fired steamship. However, its claim to fame occurred in the Saginaw River on October 5, 1967. It had just unloaded cargo in Saginaw, Mich., then as it made its way down the river, it lost power and collided with the I-75 Zilwaukee Bridge. This bridge then was a draw bridge, and often opened for ships, blocking traffic for miles. It struck the southbound lane of the bridge knocking it out of commission for sometime. The SCHOELLKOPF suffered little damage, but the incident helped bring about the present Zilwaukee Bridge high over the river.

In 1973 the SCHOELLKOPF was sold to the Erie Sand Steamship Co., but not renamed. On November 9, 1974 I photographed it at Port Huron, Mich. after it had unloaded a short distance away. I am not sure why the unloading boom was so far out, but its smoke was spectacular!

In 1975 its boilers were converted to oil burning, but just four years after it last sailed, laying up in Dec., 1979. It had put in 72 years, and that as a steamer, which is itself quite a record for service! One last trip under tow took the J. F. SCHOELLKOPF JR. to far away Italy for scrapping in 1980.

(Text by Richard Wicklund. Photos by Peter J. Van der Linden and Richard Wicklund.)

|

| 2 The J. F. SCHOELLKOPF JR., was photographed by Richard Wicklund on November 9, 1974, at Port Huron, Michigan. (It was built in 1907, as the straight deck bulk freighter HUGH KENNEDY, by the American Shipbuilding Company in Lorain, Ohio.) Carl Mottern Why is the boom being swung underway as they near a potential bridge/boom collision? Mark Gilson They couldn't hit any part of the Blue Water Bridge if they tried, can't get close enough. As they just left the unloading dock, it looks like the Captain was in a hurry to leave (maybe other river traffic?) and departed before the ballast was pumped in fully to compensate for the weight of the boom as it's brought inboard and secured for sea. I'm sure the boom was inboard even before they reached the vicinity of the bridge and it would've been interesting to see in a sequence of photos as she headed upbound. Hindsight is always 20/20... Carl Mottern Mark Gilson thanks for the clarification. I once saw an Algoma Boat swing its boom Between lock 3 and the Skyway. I was wondering why risk that? John Clark Most interesting photo, smoke is awesome sight. Looks like securing the boom would be correct, two crewmen looking at it and the operator window/door is open, odd but logical. I'll settle for that Sean Whelan They may have been putting on the hatch tarps. |

This posting taught me that you can't tell if a boat is a self-unloader just by looking.

Dan Drella posted the question: "They had a big section of the Blough open on both sides at the stern. Any idea what Work is being done there?"

|

| David Seehafer commented on Dan's posting The opening in the stern of the Roger Blough is where the unloading boom is stored when not in use. Here is a picture of the unloading boom extended. In short, Blough has always had a hole in her hinder. |

|

| Robert Campbell posted This photo of the Roger Blough by the late John Vournakis shows the ship at Gary Indiana on January 10, 1973. Dennis DeBruler: In the left background, you can see the unloading boom extended from its stern. |

|

| David Seehafer commented on Dan's posting Stewart J Cort is the same way |

|

| David Seehafer commented on Dan's posting Edgar B Speer has a short boom as well but hers is stored on deck rather than in the hull |

Speaking of the Roger Blough

|

| Mark Duskey posted Mong Rockey I didn't know the Roger Blough was an M/VMong Rockey M/V MEANS motor vessel |

This illustrates the labor and dock-side capital that self-unloaders save.

|

| Ben Stalvey posted Who says you need a self unloading ship. LOL just use a fleet of Manitowocs Ron Nadeau Salem mass. Power plant the 4000w in the middle only one still running. Ben Stalvey David Guarino Ben Stalvey No idea if the cranes are gone but the power plant is. Ron Nadeau Early 8os [This is a demonstration of why the industry is moving to big barges with big towboats. It allows the expensive machinery part (towboat) to make money somewhere else while the barge is being unloaded. And because the cost of wasted assets during docking for a barge is a lot less than for a boat, they don't have to go to the expense of having a self-unloader in the cargo bay.] |

|

| Carl Burkett commented on a posting I was pretty amazed with the self unloading equipment parked in her big fat arse. [I can't determine exactly which boat he is referring to. (Update: I noticed this photo in his Roger Blough posting.)] |

|

| Dale Pohto posted The Irvin L. Clymer unloading at the Diamond stone dock in Fairport. The A. E. Staley grain complex is visible in the background, across the river. Vincent Minello: What year is that ? Dale Pohto: Vincent Minello The ship was renamed Irvin L. Clymer in 1951 but she has no radar yet, so it's very close to that date... |

I saved this photo because the unloader on the bow is rather rare. It is unloading at Shelly Materials.

|

| Paul Hodson posted Cuyahoga River in Cleveland. View from the plane. |

|

| David Schauer posted Another entry in the unusual category is this image of the Paul R. Tregurtha doing some spring cleaning of its holds prior to its first trip of the season (coal at Midwest Energy). 4/2/2022 Dave Wagner: Running off the belt , cleaning up the tunnel. |

This made me wonder how many motors are needed by the unloader.

|

| Adam Stromquist posted I forgot I took this. From atop of the unloading boom structure of the Presque isle. We took out one of the 500 hp electric belt motors of the unloading system for a rebuild. She looks even longer from this vantage point. June 5th, 2022. Duluth MN Dan McCusker: That’s a big motor! I am a construction electrician and I think the biggest motor I’ve wired is a 50 HP 480V 3 phase unit. What supply voltage do they run on? Adam Stromquist: Dan McCusker that I do not know. I believe the guys run 480 3 phase to the ship for winter layup so it's probably in that range. |

|

| 4:14 video @ 0:32 (source) Mike Rezabek: Our gates are quite different from this video. Instead of side to side opening clamshells, we have fore and aft opening slide gates. Same concept, but different tech. Many of our ships have a single belt system, where the footers have a three belts system. |

A term for older boats that haven't been converted to self-unloading is "gearless." [Carl Burkett comments in a posting] (Facebooked, 61) In that same posting Carl Burkett found the first self unloader on the Great Lakes. It was way back in 1908 with a triple expansion steam piston engine.

In 1932, W. E. Fitzgerald was the first U.S. self-unloader to go through the (fourth) Welland Canal. [BoatNerd]

A video of a clamshell crane in operation (source)

Hulett unloaders are no longer needed to unload ore boats. The tall black structures on the side of the big grain elevators in Buffalo are also unloaders that have been made obsolete by the conversion to self-unloading boats. Fortunately for industry history enthusiasts, it costs too much to tear down these obsolete structures.

Danny Thompson shared twelve annotated photos of the construction of the Mark W. Barker at Sturgeon Bay.The photos have some good views of the unloading tunnel. The boom salvaged from the Middletown/American Victory is currently stored next to the ship.

It took about five hours to unload road salt.

Ozinga's dock on the Calumet River has several aggregate piles made by self-unloading freighters.

Bonus: self-unloading significantly reduced the labor of unloading freighters. Now they have developed "single point loading" to reduce the labor for loading a freighter.

%20Fans%20of%20the%20Book%20Know%20Your%20Ships%20_%20Northern%20Venture%20on%20her%20first%20visit%20to%20t.png) |

| Todd Shorkey posted |

No comments:

Post a Comment